Kraków 2005-03-14

General Dynamics F-16 A, B. 1974

Section 1974-02-02.

The modern fighter aircraft. First generation.

History of the F-16 Design.

Due to the need to find a successor to the lightweight Northrop F-5 Tiger fighter, in 1972 the US Department of Defense announced a competition to develop a lightweight fighter providing so-called daytime air superiority. The fighter was to be designed for maneuverable combat while retaining the ability to engage ground targets. The program was designated LWF (light weight fighter).

A formal request for proposals was issued on January 6, 1972, to nine American aircraft manufacturers, of which Grumman, Fairchild, McDonnell Douglas, and Rockwell declined to participate. Responses came from LTV, General Dynamics, Boeing, Northrop, and Lockheed.

Northrop’s design was a development of the P-530 Cobra concept, previously planned as the successor to the F-5. Lockheed’s design was an improved and modernized successor to the F-104. The remaining companies submitted new designs.

Since the most important parameters of the new fighter were to be a tight turn radius and high acceleration at subsonic speeds, in August 1972, the designs of General Dynamics and Northrop were announced as the winners. Contracts were signed with them to build two prototypes each, designating them the General Dynamics YF-16 and Northrop’s YF-17. The final selection will be determined by a direct comparison.

$100 million was allocated for the program, of which General Dynamics received $38 million and Northrop $39 million. The remainder went to two engine companies, Pratt & Whitney and General Electric, for propulsion development.

Although the aircraft’s entry into service was uncertain, General Dynamics approached the project as if the prototypes were already models for production aircraft. This was because, in addition to the American market (estimated at 650 aircraft), it was counting on orders from European NATO countries seeking a successor to the F-104 (estimated at 350 aircraft). General Dynamics’ marketing department conducted a massive campaign in Europe. This approach ensured a minimal cost per production fighter.

Construction of the YF-16 prototypes. 1974.

The first YF-16 prototype, NS 72-01567, with a Pratt & Whitney F-100 PW-100 engine, was officially demonstrated on December 13, 1973, at the General Dynamics facility in Fort Worth, Texas. The aircraft was then disassembled and transported aboard a C-5 transport to Edwards Air Force Base in California for comparative testing with a competitor.

The YF-16 made its first flight on January 22, 1974, but the right horizontal stabilizer was damaged shortly after takeoff, and the flight was aborted. After the damaged component was replaced, the full flight took place on February 2, 1974. For this reason, both dates are used interchangeably in literature. During this flight, the aircraft reached a speed of Mach 2 at an altitude of 12,200 m.

The second YF-16 prototype, No. 72-01568, first flew on May 9, 1974. It was already equipped with a cannon and weapons systems. The aircraft’s maximum weight was 12,250 kg. In 1975, one of the prototypes was demonstrated at the Paris Air Show. Without a doubt, the F-16 prototype was significantly simpler than those currently in production.

The competing YF-17 prototype, No. 72-01569, did not fly until June 1974. After a series of tests, the final decision was made on January 13, 1975, to choose the F-16, although YF-17 tests continued until 1976. The aircraft had two engines, which caught the attention of the US Navy, but that is the history of the F-18, discussed in a separate chapter.

F-16 design assumptions.

In designing the F-16, General Dynamics designers leveraged experience and technologies gained from the NASA space program and the X-15 rocket, while avoiding the use of expensive materials and advanced technologies. The F-16 utilized, among other materials, 78% (83%) aluminum, 5% steel, 2% titanium alloys, and 4% (2%) graphite-epoxy composites. Approximately 60% of the fuselage is made of metal plates, with less than 2% requiring heat treatment. The aircraft’s modular design significantly simplifies the development of subsequent versions and the modification of older models. These technologies resulted in a weight savings of 260 kg.

The fixed-geometry air intake module was optimized for speeds between Mach 0.8 and 1.2. This reduces its design by 180 kg compared to a variable-geometry intake.

The F-16’s design achieved a high degree of commonality with the earlier F-111 aircraft, exceeding 60% for structural components. The main landing gear wheels were borrowed from the B-58 Hustler bomber. It is powered by the same engine that powers the twin-engine F-15A Eagle. Aircraft handling is improved by the fact that many components are interchangeable, including the horizontal tail halves, flaperons, struts, and main landing gear wheels. Of the 373 airframe components, only 57 were newly developed; 59 were sourced from other aircraft, and 257 were off-the-shelf components.

The F-16 boasts highly efficient aerodynamics at high angles of attack and low speeds. Its aerodynamic configuration was thoroughly tested in wind tunnels on 46 different variants. The one chosen provides high lift coefficient at high angles of attack, ensuring controllability and stability even at angles of attack up to approximately 30 degrees.

F-16 control system.

A completely new feature was implemented for the first time: an artificial stability and active control system, which made this aircraft a pioneer in a completely new class. A new element, facilitating piloting, was the digital control system. Unlike the previously used analog system, the digital system provided faster response, allowing the aircraft to be stabilized over a wider range of flight parameters. This allowed for a change in the previously used safety margins and expanded the operating envelope, practically to the limits of piloting capabilities. This improved the aircraft’s maneuverability, although the new avionics system components increased the aircraft’s weight. The digital control system was designed with a care-free philosophy in mind, eliminating the possibility of exceeding operational limits during strenuous maneuvers, such as during air combat. During a maneuver, the pilot can focus on monitoring the enemy’s actions, pulling the stick as far towards himself as possible. The control system automatically adjusts the required control deflection, and the maneuver is executed close to the critical angles of attack, while avoiding the risk of stalling. For safety reasons, the digital version of the aircraft utilizes double the control system – three systems operate on the aircraft.

Pre-series F-16 FSD aircraft, 1976.

The YF-16’s victory resulted in a $417.9 million contract with General Dynamics for the construction of 15 F-16 FSD aircraft (full-scale development), 11 F-16 A aircraft and 4 F-16 B aircraft. Production began in July 1975. During production, the order was reduced to 6 F-16 A aircraft and 2 F-16 B aircraft.

The first F-16 A FSD aircraft left the factory on October 20, 1976, and first flew on December 8, 1976. The second aircraft first flew on February 25, 1977. The first F-16 B FSD aircraft first flew on August 8, 1977.

During the F-16’s research and development, it was decided to revise the LWF program. It was determined that the F-16 should complement the expensive F-15. Therefore, the ACF (air combat fighter) program was launched. The program’s goal was to enhance the aircraft’s combat capabilities, primarily through the installation of an AN/APG-66 radar, an upgraded navigation system, and a wider range of air-to-ground weapons.

Other changes were also made: the wings are slightly larger than those of the prototypes, and the horizontal tail has an area approximately 15% larger. The airbrakes were enlarged. Pre-series aircraft received enlarged noses to accommodate the radar. This resulted in a longer fuselage. The structure was reinforced to fully utilize the aircraft’s maneuverability, primarily in the rear fuselage. Nine suspension nodes were installed, and their payload capacity was increased. Many epoxy-carbon composite components were used, including the main landing gear covers, some engine inspection covers, and aerodynamic vanes under the fuselage. The nose landing gear bay received a single-piece hatch instead of two symmetrical halves. Finally, a landing hook was added to catch the aircraft at the end of the runway. Pre-series aircraft were used for comprehensive flight testing. During tests under various conditions, nine AIM-9 Sidewinder guided missiles were fired, 12,948 cannon rounds were fired, and ten Mk.84 bombs were dropped.

Contract of the Century for NATO Countries.

While prototype tests were still underway, the aircraft was presented to European NATO countries, which were seeking a fighter for the 1970s and 1980s. In the competition, held in the mid-1970s, the YF-16 emerged victorious, edging out the Mirage F.1 (France) and SAAB J-37 “Viggen” (Sweden). This was because General Dynamics offered European NATO countries cooperation in its production, which benefited them by revitalizing their own aviation industries and adopting new technologies.

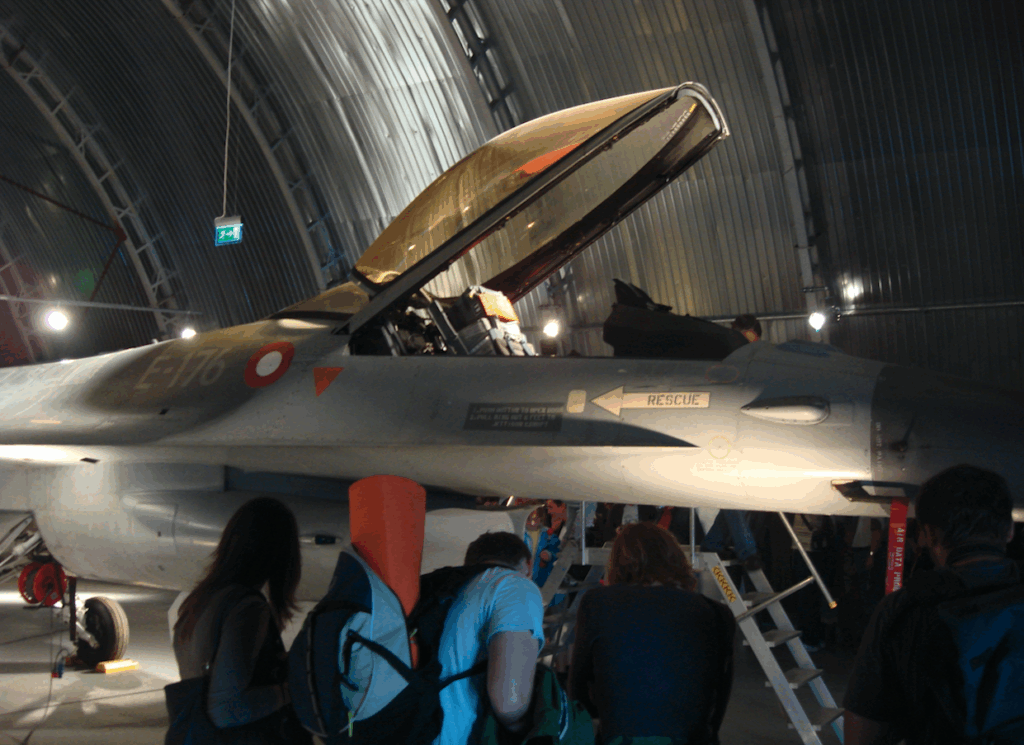

In February 1975, the aircraft were offered to Belgium, Norway, the Netherlands, and Denmark, at a price of $5.16 million each. On June 7, 1975, it was announced that initial deliveries would include 116 aircraft for Belgium, 102 for the Netherlands, 72 for Norway, and 58 for Denmark. Aircraft companies from these countries were included in the F-16 production program in the following proportions: 10% of each aircraft for the USAF, 40% of each aircraft for European customers, and 15% of each aircraft for third countries. This was a very favorable arrangement for European manufacturers. Final assembly of the aircraft was located at Fort Worth, USA, Fokker-VFW in Schiphol near Amsterdam, Netherlands, and Sonaca/Sabca in Gosselines, Belgium.

F-16 A Fighting Falcon. 1978

In the spring of 1978, the US Secretary of Defense signed the long-awaited contract for series production of the F-16 A/B fighter. This was the first production variant. The first F-16A, aircraft number 78-0001, powered by a Pratt & Whitney F-100 PW-100 target turbofan engine with 1 x 10,818 kgf (10,818 kG) of afterburning thrust, flew on August 7, 1978. Test pilot Neil Anderson was at the controls.

On October 31, 1978, the first F-16A with European-made wings flew.

From January 1979, the first production fighters entered service simultaneously in the United States and Western Europe. In the United States, they were deployed to the Hill Air Force base in Utah, and combat readiness was achieved in October 1980. Deliveries to customers began in Europe; Belgium – built on January 29, 1979, delivered to the military on March 23, 1979; the Netherlands – built on May 10, 1979, delivered to the military on June 7, 1979; Norway and Denmark – delivered to the military in January 1980. In July 1980, the aircraft received the official name Fighting Falcon.

From 1984, the Americans introduced the F-16 A/B to their units in South Korea, West Germany, and Spain, as well as to the National Guard (defense of the US territory).

F-16 B.

A two-seat combat trainer version derived from the F-16A, with unchanged external dimensions but reduced internal fuel tank capacity to 2,620 kg, a reduction of 550 kg. Unlike Soviet combat trainer aircraft, the F-16B is a fully combat aircraft.

F-16 Wild Weasel Program. 1978

On April 7, 1978, General Dynamics, despite the lack of a formal order from the USAF, began work on a version for countering ground-based radars. A pre-production F-16B FSD No. 75-0751 was used for testing the new version. The aircraft was equipped with wingtip antennas, an AN/ALQ-131 WRe warfare system under the fuselage, and underwing armament: AGM-88 HARM, AGM-45 Shrike, and AIM-9J Sidewinder. However, the military did not order this variant.

F-16 A/B Block 15/20. 1981.

As early as 1980, a multinational, multi-stage F-16 modernization program, designated the Multinational Staged Improvement Program (MSIP), was launched within the Enhanced Tactical Fighter ETF program. Its goal was to develop a tactical fighter capable of carrying out the most complex combat missions in all weather and time of day conditions, and in complex operational and tactical situations.

Due to the complexity of the issues, the MSIP program was divided into three stages. The first, MSIP-I, saw the creation of F-16 A/B Block 15/20 aircraft, receiving only the necessary structural changes and a reinforced power plant for future needs. Work began in 1981. Subsequently, the following were implemented: Some new equipment, the ability to carry new weapons and related equipment (sensors), the installation of a drogue parachute in an extended vertical stabilizer base fairing, and an enlarged horizontal tail with a lighter structure.

F-16A Block 15 OCU.

F-16A Block 15 OCU – a modernization program for the F-16A Block 15 aircraft operated by the Air National Guard and several other nations.

F-16 C. 1982

There was no doubt that the aircraft needed to increase its combat capabilities. The problem was that the F-16 A/B was excellent against the widely used MiG-21, but it was already struggling against aircraft equipped with medium-range guided missiles. Therefore, in February 1980, a version capable of engaging medium-range AMRAAM guided missiles was developed. However, this did not stop there, and the development program was significantly expanded. It was designated MSIP. However, due to the enormity of the changes, it was divided into stages, as discussed in subsequent chapters.

Major avionics modifications and their enhancement, along with the increased ability to employ a variety of weapons under the MSIP-II/-III programs, led to the introduction of the F-16 C Block 20/25 type for newly produced aircraft. External differences are limited to an extended vertical stabilizer base to accommodate the ASJP jamming system. The radar is a Westinghouse AN/APG-68. The first F-16 C aircraft flew on December 14, 1982.

F-16 D.

The F-16 D is a two-seat, two-control variant derived from the F-16 C and differing from the previous F-16 B in having an extended vertical stabilizer nose, as on the base aircraft.

F-16 / General Electric F-101 engine. 1980.

The General Electric F-101 engine was developed to power the B-1 strategic bomber and became the subject of joint USAF and US Navy research into alternative powerplants for the F-14 and F-16 aircraft. In 1980, a pre-series F-16 A FSD aircraft, No. 75-0745, was equipped with the General Electric F-101 DFE (Derivative Fighter Engine). The aircraft differs externally from P&W-engined aircraft in the shape of the exhaust nozzle, due to the different airflow requirements. The first flight was performed on December 19, 1980. Tests lasted for a total of 100 hours and were completed in July 1981. As a result of the aircraft’s test flights, this engine became the replacement turbofan powerplant for the F-16. However, work on the General Electric F-101 engine continued and culminated in the development of the General Electric F-110 GE-100 engine, with 1 x 72.0 kN thrust and 1 x 128.8 kN with afterburning, which was installed in series on the F-16 from 1986. From that point on, the aircraft have two alternative powerplants. The type of engine used is distinguished by its numbering; Block X0 is a GE engine, Block X2 is a P&W engine. Polish F-16 aircraft have P&W engines.

F-16 Production and Operations

Initially, the USAF ordered 552 and 98 F-16s (single-seat and two-seat), respectively, and 290 and 58 for four European NATO countries, respectively. Plans for the USAF even called for 1,184 and 204 F-16s, respectively.

The US production line delivered 74 F-16 A/B aircraft by January 1980, while 34 F-16 A/B aircraft were built in Europe during the same period. The pace of production is demonstrated by the fact that the USAF received its 300th F-16 in December 1980. At the beginning of the 1980s, the order was increased to 2,795 aircraft, including 1,859 for delivery by February 1985. The production rate increased from 150 to 180 units per year in 1987, with a projected increase to 216 units per year in 1989.

The following aircraft were built: F-16 A/B Block 1 – 43 units built (21 F-16 A and 22 F-16 B). These aircraft differ little from the pre-production F-16 FSD. F-16 A/B Block 5 – 126 units built (99 F-16 A and 27 F-16 B). Reliability was improved and ground operability was improved. F-16 A/B Block 10 – 170 units built (145 F-16 A and 25 F-16 B). F-16 A/B Block 15 – 457 units built (416 F-16 A and 41 F-16 B).

The term “Block” (series) deserves clarification. Traditionally, in the United States, a modernized variant of a type receives the next letter of the alphabet, although there were exceptions that prove the rule. However, in the case of the F-16, despite the initial letters A, B, C, and D, the designation “Block” became standard, which conveys much more about the aircraft’s combat capabilities. This was because most of the aircraft were produced in the early 1980s and subsequently modernized during their service.

Four European NATO countries—Belgium, the Netherlands, Denmark, and Norway—produced 348 F-16s in cooperation with the United States for their own use, supplementing this by importing pre-built aircraft.

Belgium in 1979, the first F-16B, no. FB-01, was delivered on March 23, 1979. Belgium received 96 F-16A Block 15s and 20 F-16B Block 15s. In 1988, 40 F-16A Block 15s and 4 F-16B Block 15s were upgraded to the Over-the-Counter Unit (OCU) version. In 2000, Belgium had 129 F-16A/Bs in service and 39 in storage. It was planned that 110 aircraft would undergo a major modernization in the following years. According to current data, by July 2025, Belgium had 42 F-16A/B MLUs, and they are being systematically replaced by F-35A Lightning IIs.

Netherlands 1979 – The first aircraft was delivered to the army on June 7, 1979. Deliveries were completed in March 1982. The Netherlands received 131 F-16A Block 15s and 31 F-16B Block 15s. In 1988, 46 F-16A Block 15s and 5 F-16B Block 15s were upgraded to OCU standard. In 2000, the country had 157 upgraded F-16A/B MLUs. Currently, the Netherlands no longer has any operational F-16s. All have been retired, and a significant number have been transferred to Ukraine. The last flight of the F-16s took place on September 26, 2024, marking the end of their active service with the Koninklijke Luchtmacht. The Netherlands transferred 24 F-16AM/BMs to Ukraine. The last aircraft departed from Volkel on May 26, 2025. Another 18 aircraft were transferred to the European F-16 Training Center in Romania, while others serve as sources of spare parts or were transferred to private companies.

In 1980, Denmark received its first order for 46 F-16A Block 1/5/10 aircraft and 12 F-16B aircraft. Deliveries were made between 1980 and 1984. In 1984, eight more F-16A OCU Block 15 aircraft and four F-16B OCU Block 15 aircraft were ordered and delivered in 1987. Three more aircraft were subsequently purchased to partially replace the loss of seven aircraft. In 2000, the country had 68 F-16A/B aircraft, yet to be modernized. In 2023, the country had 54 F-16 aircraft. In 2025, Denmark will have no F-16 aircraft. Denmark transferred 24 F-16 aircraft to Argentina in April 2024. Also in 2024, Denmark transferred 19 F-16 aircraft to Ukraine.

Norway, 1980. The first flight of a Norwegian aircraft took place on December 12, 1979. Norway ordered 60 F-16A aircraft and 14 F-16B aircraft. Deliveries lasted from January 15, 1980, to June 4, 1984. In 2000, the country had 57 F-16A/B aircraft, not yet modernized. The last F-16 was retired on January 6, 2022, and combat duties were taken over by the F-35A. According to available information, 32 aircraft were transferred to Romania, and over 20 aircraft were delivered to Ukraine.

Portugal, 1994. After considering the sale of used F-16 A/Bs to the United States, Portugal decided to purchase 17 new F-16 A Block 15 aircraft and three F-16 B Block 15 aircraft. The first four aircraft arrived by air on July 8, 1994.

Israel 1980. The country was the first non-NATO country to order F-16 A/B aircraft. The initial order amounted to 75 (67/8) F-16 A/B Block 15s. Deliveries began in January 1980. Israel is proud of the first combat use of F-16s. On July 7, 1981, F-16s attacked an Iraqi research facility with a nuclear reactor in Tamuz, near Baghdad. It didn’t take long for Israeli F-16s to participate in the invasion of Lebanon in April 1982. The next delivery of 75 (51/24) F-16 C/D Block 30 aircraft with F-110 GE-100 engines began in December 1986. In 1991, a third delivery of 30/30 F-16 C/D Block 40 aircraft followed. In 2002, the Israeli Air Force had a total of 237 F-16s, more than half of which were C/D variants with innovations designed exclusively for Israel. In 2024, Israel had 174 F-16 C “Barak” and F-16 I “Sofa” (two-seat combat aircraft).

Egypt currently possesses up to 220 F-16 aircraft of various versions. After the USAF, Egypt is the country with the largest number of Lockheed Martin F-16s. Total deliveries amounted to 244 aircraft.

Jordan initially ordered 16 F-16 A/B variants. The order has since been increased to 59 aircraft: 44 F-16A/AM (single-seat) and 15 F-16B/BM (two-seat). Jordan has ordered 12 additional F-16C/D Block 70 aircraft, with delivery by 2027.

Pakistan 1983. The contract was signed on December 18, 1981. Thirty-two F-16A and eight F-16B aircraft were ordered. Minor modifications were made before the contract was implemented, and ultimately, between January 1983 and 1985, 28 F-16A Block 15s and 12 F-16B Block 15s were delivered. These aircraft shot down Afghan fighters violating Pakistani territory several times in the second half of the 1980s. Plans were made to purchase another 71 F-16s. Production of the aircraft began, but deteriorating diplomatic relations with the United States prevented the contract from being fulfilled. The Pakistan Air Force currently operates approximately 75 F-16 fighters of various versions: the F-16AM/BM Block 15 MLU, the F-16A/B ADF, and the more modern F-16C/D Block 52+. Venezuela, 1983. In South America, only Venezuela possesses the F-16. In May 1982, a contract was signed for the delivery of 24 (18/6) F-16 A/B Block 15s. The contract was almost terminated when the US offered F-16-79 aircraft, which, according to the military, would not provide sufficient range. The number 79 refers to the old J79 engine. Ultimately, the F-100 PW-100 engines were approved. On November 16, 1983, the first six aircraft were delivered, and the military took them into service in December 1983. Currently, Venezuela has a relatively small number of operational F-16s. Although it historically had 24, only a fraction of them are currently operational.

Thailand, 1988. The country planned to purchase the F-16-79, but ultimately opted for the F-16 A/B Block 15. The contract was signed in December 1987. The first of 12 F-16 A/B Block 15s was delivered in May 1988. These were presumably not new aircraft, but rather from USAF inventory. A further 18 (22) F-16 A/Bs were ordered in January 1992, with the first aircraft delivered on September 11, 1995, followed by another 16 F-16 A/Bs withdrawn from the US fleet. A total of approximately 50 aircraft. According to the latest data, the Royal Thai Air Force maintains 48 F-16s of various versions, including the A/B Block 15 ADF, OCU, and the modernized F-16AM/BM Block 20 MLU.

Indonesia 1989. The country signed an agreement in August 1986 for the delivery of 8 F-16 A Block 15 and 4 F-16 B Block 15. The Indonesian Air Force (TNI-AU) currently operates 33 F-16 aircraft of various versions: F-16A, F-16AM/BM (modernized, formerly A/B), F-16C/D (remanufactured, often designated F-16ID or Block32+).

Singapore 1990. In January 1985, the country signed a contract for the delivery of eight F-16-79s. When it became clear that the program had been discontinued, the contract was canceled. It was not until February 1990 that four F-16A Block 15 OCUs and four F-16B Block 15s arrived in Singapore. On June 9, 1994, an order was placed for eight F-16C Block 50D/52Ds and ten F-16D Block 50D/52Ds. Deliveries were made from March 1998 to December 1999.

Taiwan 2000. The country operated 146 F-16 A/B Block 20 aircraft. Currently, Taiwan has over 139 F-16V (Block 70/72) aircraft and is accepting 66 new F-16C/D Block 70 aircraft, which will be delivered by the end of 2026.

Japanese license production of the F-16 J/DJ. 1989. A program for a new fighter aircraft for the Japan Self-Defense Forces was designated FS-X. Since it was determined that the Japanese economy was unable to develop its own modern fighter aircraft on its own, it was decided to take advantage of the US proposal and license-purchase the F-16. However, this was not a pure copy, but rather the maximum possible unification of their equipment with the American design. Avionics and armament were the first to be developed. The Japanese used domestically produced equipment: radar, computers, and weapons, primarily ASM-1 guided missiles. Anticipating the increased weight of the equipment, the Japanese requested that General Dynamics increase the landing gear’s strength to 21,780 kg and install a drogue parachute. Many components were made of composites instead of metal. Even entire composite wings were planned. Plans were made to manufacture the powerplant in-house, with the F-100 PW-229 or F-110 GE-119 engines. The aircraft was officially designated the Mitsubishi F-2A – a single-seat version based on the F-16C – and the Mitsubishi F-2B – a two-seat version based on the F-16D. In the United States, the aircraft were designated F-16 J/DJ. Japan planned to acquire 130 aircraft. By 1989, Mitsubishi had already produced approximately 20 domestically produced F-2 fighters. Production ended after 98 units had been built, including four prototypes.

This chapter does not describe the F-16 aircraft in Poland, as this topic is covered in other chapters.

Written by Karol Placha Hetman