History

Kraków 2014-10-11

Boeing B-747 – Amazing plane.

When the B 747 was flown on February 9, 1969, it was the world’s largest aircraft. It turned out to be very successful in operation and its success exceeded the expectations of its designers. I don’t think anyone expected that. And although there were several sharp turns in its history, the B 747 has become an unusual plane and will continue to travel through air routes for many years to come.

Prologue.

then what was happening had a huge impact and set the standard for air cargo and passenger communication for several decades. Two paths of development were then created; faster or more (goods or passengers). The first road hardly led to the bankruptcy of such aviation companies as Boeing, North American, Lockheed, McDonnell Douglas, and in Europe, Aerospatiale. No doubt the airlines dealt the cards in this game. They have always been looking for such planes to earn good money with their help. And that has not changed since the 20s of the 20th century. In the case of supersonic airplanes, the main problem was that the ticket price was too high, which did not compensate for even a few hours reduction in travel time. Therefore, airlines gradually withdrew from participating in supersonic aircraft construction programs, and saw their benefit in cramming as many passengers as possible on one plane. But here, too, there were some barriers that the client, the passenger, did not want to accept. One of them was the low frequency of connections. In commercial aviation, the balance between cost and effect always counts. Airlines know very well how big a plane can bring them measurable profits. The only problem is to hit the market with the right size and beat the competition. This is what happened with our hero, the Boeing B-747. But the career of the B-747 began with a military transport aircraft.

In 1961, several American aviation companies began developing a heavy turbojet transport aircraft to replace the then used Douglas C-133 Cargomaster and Lockheed C-141 Starlifter. Political and military considerations were needed to ensure the transport of large amounts of cargo to Indochina. In 1963, Lockheed introduced a new concept for the CX-X transporter with a curb weight of 250,000 kg, a maximum payload of 82,000 kg and a speed of 919 km / h. The dimensions of the cargo space were: 5.20 m wide x 4.10 m high x 30.00 m long, accessible through both the front and rear loading doors. The plane was to be powered by 6 turbojet engines. On this basis, in 1964, the USAF developed a new specification for the CX-HLS (Heavy Logistics System) machine, which was to be powered by only 4 engines. In late 1964, the carrier specification was sent to the Boeing, Douglas, General Dynamics, Lockheed and Martin Marietta aviation factories.

In the first half of the 60’s, US aviation had turbojets up to 100 kN. Such an engine could not drive the new military transport, which was supposed to have only 4 engines. In connection with the SST (Passenger Supersonic Aircraft) program, work has already begun on high-thrust engines; GE-4 with a thrust of 290 kN. However, such engines have different rules due to the speeds achieved. Subsonic engines with a thrust of 180 kN were needed for the designed transport aircraft. Therefore, the engine development was proposed to Curtiss-Wright Corporation, General Electric and Pratt & Whitney. The former withdrew from all programs and soon shut down.

The General Electric company developed the TF39 turbofan engine (military version for the C-5 Galaxy) with a thrust of 180 kN, which was designated CF6 in civil aviation.

The Pratt & Whitney company developed (1966) the JT9D turbofan engine with a thrust of 180 kN. It was the original propulsion of Boeing B-747 aircraft.

Both engines marked the beginning of large families of turbofan engines that have resulted in the construction of many successful commercial aircraft.

Two companies have entered the main stage of the CX-HLS competition; Lockheed and Boeing. At the end of 1965, the USAF committee chose Lockheed’s design with General Electric engines, and thus the C-5 A Galaxy was created.

It is worth comparing both projects; Lockheed and Boeing. Both in size and mass were similar. In both, the crew cabin (cockpit) was raised high to ensure the installation of loading doors both at the front of the fuselage and at the rear. Both had an identical power unit (4 engines in individual nacelles suspended under the wings). However, there was a serious difference; the Lockheed design is a high wing and Boeing is a low wing (although Boeing also considered the high wing configuration). There are two main consequences of this difference. The high wing has a hold floor lower than the low wing. And the high-wing due to the center wing has a naturally reinforced upper fuselage, so the installation of ceiling winches and transport cranes does not require reinforcing the structure.

The Boeing concern.

The Boeing concern in the 1960s was called the Boeing Aircraft Company. The company was founded in 1916. In the second half of the 70’s, it was already the largest aviation company in the world. Today (2014) Boeing is the world’s largest aviation company, a leading manufacturer of commercial aircraft, military aircraft, helicopters, satellites, weapons, defense systems, electronic systems, advanced information systems and communications. Boeing’s customers are located in 150 countries. The concern employs 169,000 people in the US and 65,000 in other countries. Boeing is divided into two business units: Boeing Commercial Airplanes and Boeing Defense, Space & Security. These units are backed by; Boeing Capital Corporation, a global provider of financing solutions; Shared Services Group, which offers a wide range of services to Boeing around the world; Boeing Engineering, Operations & Technology that helps develop, acquire, apply and protect innovative technologies and processes. Over the years of its operation, Boeing has built more than 12,000 commercial turbojets. The novelties of recent years include; B 787-10, B 737 MAX, B 777 X.

Boeing 747. 1969 year.

After Boeing lost in the CX-HLS competition for the USAF (late 1965), it seemed the project would hit the shelf. However, Pan Am airline was very serious about the big airliner by submitting an initial bid for 10 passenger aircraft.

Where did Pan Am’s interest in such a large passenger plane come from?

Pan Am airline was one of the precursors of the jet era in commercial aviation. In 1955, it placed an order for the Boeing B 707 commercial aircraft. With these aircraft, it inaugurated the transatlantic connection from New York Idlewild to Paris Le Bourget, landing technically for fuel matching in Gander (a city in Canada, in the provinces of Newfoundland and Labrador). The first flight was made on October 26, 1958 on a Boeing B 707-121 Clipper America (N711PA) with 111 passengers. Subsequent B 707-320 (1959) and DC-8 (1960) models allowed Pan Am to fly to Europe without stopping. More European cities have appeared in the network of connections; Amsterdam, Rome and others. Pan Am has become the dominant player on the transatlantic lines and is making good money from it.

No wonder then that the boss of Pan Am Juan Trippe asked his friend William McPherson "Bill" Allen, one of the bosses of the Boeing concern – On the basis of an already developed large transport plane, would they build a passenger plane, much larger than the B 707, capable of non-stop flight New York – Rome? William McPherson "Bill" Allen, on the other hand, began to analyze the subject with the president of Boeing, Malcolm T. Stamper. Everyone agreed that it would be a transitional aircraft, as supersonic aircraft were already being developed. Boeing executives were not immediately willing to take the risk. Boeing has sent relevant inquiries to other airlines; TWA (Trans World Airlines), American Airlines, United Airlines, and also abroad; British Overseas Airways Corporation (BOAC), Japan Airlines (JAL), France and Australia. One of the basic questions was the capacity of the future machine. Almost all carriers indicated a capacity of 350 passengers. Boeing knew about working with competitors; MDD (DC-10) and Lockheed (L-1011). Therefore, having made a large amount of design calculations for a transport aircraft, it was decided to convert it into a transitional airliner.

The team of designers of the future B 747 was led by Joseph F. "Joe" Sutter, whose history hailed the father of the B 747 aircraft. chief designer Jack Steiner.

It is worth mentioning that at that time the USAF’s Boeing CX-HLS program had not yet been closed and was run by Rowland "Row" Brown. As the only reliable recipient of the future aircraft was Pan Am, therefore Joseph F. "Joe" Sutter began working with their chief engineer John G. Borger. This suggested that the fuselage was in the cross section of a double bubble. It’s like stacking two B 707 fuselages. This fuselage arrangement was already used in the Lockheed R6V Constitution in 1946. However, this solution has several disadvantages, the most difficult of which was evacuating all passengers and crew in 90 seconds. This standard was already in force then. Ultimately, in March 1966, Pan Am Airlines chose the concept of a single passenger deck. Interestingly, the design of the aircraft’s bow was designed to accommodate front cargo doors in the future. Remember that the plane was supposed to be a transitional one and a relatively young fuselage could be converted into a cargo transport. This is also why the crew cabin has been left high in a distinctive hump, similar to the C-5 Galaxy. The upper deck, behind the cockpit of the crew, was to be exclusively at the disposal of the crew and cabin crew. It was planned to place an observation deck there. However, in the following already produced versions, passenger cabins were also placed here. 69 people can travel here in a 3×3 seat configuration. In some variations, they can accommodate 150 passengers.On April 25, 1966, Pan Am Airlines signed an order for the B 747 for $ 525 million. This amount rose to $ 550 million. The Pan Am airline company secured the first 5 machines and the first machines in each new series, i.e. after the construction of 50 B 747 machines, half of them went to Pan Am. Importantly, only 50 machines were to be built, because the next planes were to be supersonic. The signed contract was worth $ 550 million, and one B 747-100 cost about $ 18 million. Subsequent orders came from JAL and United Airlines, which ordered a total of 25 machines. Possible further B 747s were to be produced as cargo.

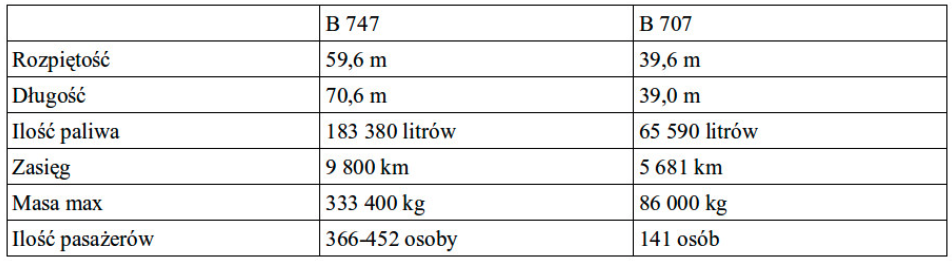

With the introduction of the B 747 into service, it was natural to compare with the predecessor B 707.

In the fall of 1966, the Boeing CX-HLS program was permanently shut down. Engineers from this program were transferred to the B 747 program. Malcolm T. Stamper became the head of the B 747 program, who became responsible for the economic and administrative side. Joseph F. "Joe" Sutter remained the chief designer.

On December 22, 1966, the head of Pan Am, Juan Trippe, signed a letter of intent to purchase 25 B 747s, which was the result of work on the aircraft by Boeing and the approval of the Pan Am Board of Directors. On December 27, 1966, the contract was signed. As early as the spring of 1966, Pratt & Whitney guaranteed the Boeing concern that it would undertake further work on the JT9D engine as long as the B 747 program was implemented.

Remember that at that time Boeing’s priority was the supersonic B 2707. The team of this program worked in a modern Development Center. The B 747 team, on the other hand, had much worse housing conditions, and individual offices were scattered throughout the area. In addition, it turned out that Boeing did not have a production hall large enough to accommodate such a giant. A proposal was made to build a new assembly plant in California. It was a typically political game, because competitors’ plants were located there; Lockheed and Douglas, and the state of California had a much larger breakthrough in the US Congress. However, the design team pointed to possible long delays in the program due to the significant distance of the office from the assembly plant. This argument won, and Malcolm T. Stamper found a convenient square in Everett, 25 miles (about 50 km) north of Seattle. The square was 780 acre (about 315 hectares) in size and was in fact a former military airport. In this area, a new 10,000 ft (3,048 m) runway and other facilities were built at a cost of $ 200 million. These include a huge aircraft assembly building with a cubature of 13,385,378 m³ and an area of 399,480 m². To date (2014), it is the largest building in the world. Airplanes have been and are produced here; B 747, B 767, B 777 and B 787. As a reminder, let us mention that planes; The B 707, B 727, B 737 and B 757 arose and are being built in Renton. In May 1967, the assembly of the first production equipment began. In 1967, the entire engineering team was already working in Everett.

Constructing the B-747.

Wings. Initially, for the B 747 the wings were to have an area of 5,200 ft2 (approximately 483 m2). However, due to the prospect of suspending the take-off weight of the freight version, this area was increased to 5,650 ft2 (approximately 525 m2). Pan Am management insisted that the cruising speed should be Ma-0.88. Boeing wanted to maintain the Ma-0.82 cruising speed and thus maintain a wing angle of 35 degrees, as with the B 707. Higher speed would require a 40 degree angle. Jointly agreed cruising speed at Ma-0.85 and a wing pitch of 37.5 degrees. The wing received a rich mechanization; Kruger flaps, Fowler flaps, spoilers, double ailerons. The idea was to maintain the take-off and landing speed as well as the length of the in-run and roll-out in the regimes. After all, no one will build new, long runways for the B 747. During tunnel tests, it turned out that the wing tips create more lift than necessary and unnecessarily strain the girders. The simple solution was to aerodynamically twist the outer parts of the wings. The chassis was designed for a weight of 272,000 kg, which was later increased to over 300,000 kg. Therefore, it was necessary to properly distribute the pressure on the surface. A front chassis plus three four-wheeled main chassis are planned. But eventually the main landing gear got four four-wheeled bogies. Nay. The wheels and braking systems were taken from the B 707 which proved to be a good solution.

Prototypes B 747-100.

On 09/30/1968, the first prototype was rolled out in Everett. The plane on the fuselage had the emblems of 26 airlines, which declared their intention to use the plane at home and signed letters of intent. The ceremonies were held especially for banks so that they would continue to finance the program. Only some of the factory personnel knew that the plane was only 78 percent complete, and there were still several months to go.

There were some problems with the Pratt & Whitney JT9D engines (unstable work and low stiffness of the nacelle, especially the air grip, which became oval). These problems were resolved and in April 1969. The engines were approved for initial operation with certain restrictions, with a thrust of 184.5 kN. In the first year, there were 87 engine failures and 55 power unit replacements. However, there was never an accident. We must remember that the engine of such high power was new to commercial aviation.

The flight of the B 7470 took place on February 9, 1969, in Everett from Paine Field airport. The crew of Jack Waddell, Brian Wygle, Jess Wallick. The flight was a great success, although there was a minor failure of the swingarm bearing due to a material defect. On February 15, 1969, the plane made its second flight.In April 1971, the B 2707 program was finally closed, making the B 747 a synonym for technical advances in commercial aviation.

The B 7470 prototype was not called a prototype by Boeing, but a test specimen and remained the property of Boeing until the end. It even received its own name "City of Everest". Five machines participated in the test program. Four of them were already intended for the Pan Am airlines (3 pieces) TWA (1 piece). The second copy is the B 747-121 for Pan Am, registration N747PA and proper name Jet Clipper American. Its flight test was performed on April 11, 1969, and it was delivered to the user on October 3, 1970.

Written by Karol Placha Hetman