Kraków 2020-10-29

History of the RD-9 turbojet engine

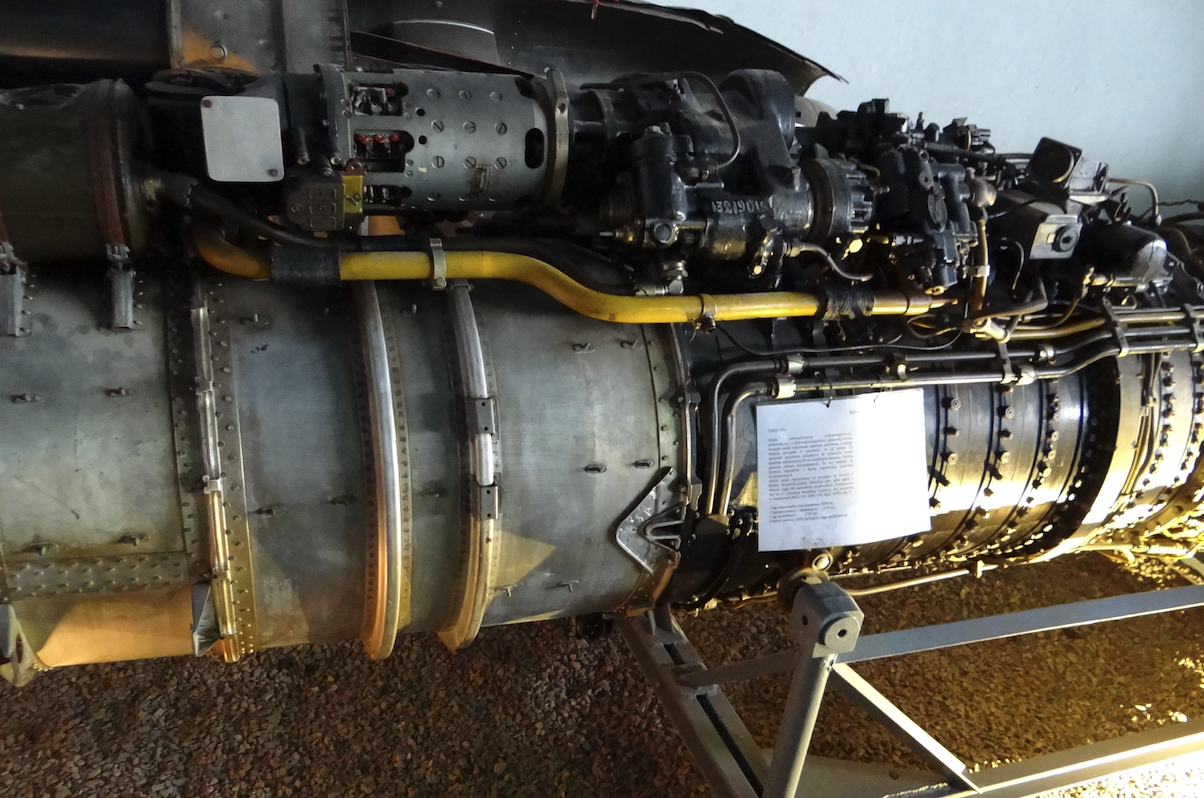

Description to the photo: The description of the engine is below. The RD-9 engine was used to power the MiG-19 fighter planes, which were also used in the Polish Army.

Work on the AM-5 / RD-9 engines. 1951 year.

Aleksander Mikulin, in addition to the large AM-3 engine, also developed the AM-5 engine with a lower power. This task resulted from the collapse of the TR-3 engine program, which had high hopes. The fall of the TR-3 engine program also plunged airframe programs, including the supersonic Su-17 (the first program with such a designation). The AM-5 engine was created in 1951 and was a scaled down AM-3 engine. The power, as well as dimensions and weight were reduced, which allowed to place this engine in a fighter class airframe. Alexander Mikulin’s team worked under time pressure. The lag of CCCP in turbojet engines lasted several years and kept growing. During the tests on the dynamometer, AM-5 engines failed frequently. Combustion chambers cracked. Turbine blades were breaking off. There were fires, usually as a result of a leak in the oil system. Almost in absentia, the program was pushed through state trials, leading to the flight test stage. To increase the chance of the program, OKB Mikojan and Guriewicz developed the I-360 (SM-2) airframe, powered by two engines, Alexander Mikulin AM-5 engines with a thrust of 2 x 1,962 kg. The prototype flew on May 27, 1952. Despite this, such a system (two engines in the fuselage + oblique wing airframe) did not provide supersonic speed. The thrust was missing. Alexander Mikulin’s team was already working on a revised version of the engine, which was designated AM-9. The AM-9 engine has a thrust of 2,550 kg. The I-360 (SM-2) aircraft was created. The plane made 132 flights and repeatedly broke the sound barrier in horizontal flight. At that time, the Americans already had F-100 supersonic fighter jets in service. The Kremlin decided to introduce the I-360 (SM-2) as a MiG-19 into service. The shortcomings of the structure were realized, but there was no exit. Other designs in the CCCP were even more delayed. The SM-9/1, which made its first flight on January 5, 1954, became a direct model of the MiG-19 serial aircraft.

In 1955, the designer Aleksandr Mikulin lost his position in OKB-300. The degradation was made by the minister of aviation industry, Pavel Dymitriev (Пётр Васильевич Дементьев). By the way, Paweł Dmitriev was the minister of the aviation industry in the CCCP from 1953 to 1977, when he died. At CCCP, this position was for life !? Aleksandr Mikulin was succeeded by Sergey Tumański (Сергей Константинович Туманский 1901-1973), his deputy. Sergey Tumanski in 30 years worked at the Центральный институт авиационного моторостроения named П.И. Баранова (Central Institute of Aviation Engines). Initially as a senior engineer. In 1938, he was the chief designer of the M-88 piston engine. In 1943, he joined Alexander Mikulin’s team, and from 1955, he was the main designer. In 1956, the AM-9 engine designation was changed to RD-9. The team managed to increase the thrust of the RD-9 engine to 3,300 kG with afterburning.

The RD-9 engine was manufactured in CCCP and China, where it was used the longest in the world. Chinese planes with RD-9 engines were exported to Pakistan. In addition to CCCP, the RD-9 engines were used in those countries that operated MiG-19 aircraft.

The RD-9 engine was used in the MiG-19 S, MiG-19 P, MiG-19 PM, Jak-25 and in the whole series of "E" planes that gave rise to the MiG-21 fighter. Overall the engine was successful, but had a few drawbacks. For example, the oil system was placed above the engine and fires occurred when it was unsealed. In the MiG-19 S, MiG-19 P and MiG-19 PM planes, the drive is composed of two engines, which made the plane a heavy fighter and inferior to its competitor, i.e. the North American F-100. The MiG-19 plane had one more serious drawback. During the run-up (take-off), when one of the engines stopped working (failure), the plane had such large thrust asymmetry that the pilot could not keep the plane on RWY.

Basic data of the RD-9 engine:

Thrust without afterburning 2 600 kG. Draft with afterburning 3 250 – 3 300 kG. Fuel consumption at a cruising speed of 0.84 kg / kGxh or 1,470 kg / h for the MiG-19. Length 5.56 m. Diameter 0.67 m. Weight 725 kg. The engine has a 9-stage axial compressor. There is an air bleed on the fifth stage of the compressor which opens automatically depending on pressure. The combustion chamber consists of 10 glow tubes that are surrounded by a common mantle. Part of the air flows between the pipes and the jacket, cooling the combustion chambers. The gas turbine has two stages. An afterburner is located at the rear of the engine, which increases the engine thrust by about 700 kg, i.e. by about 27%. The engine has an adjustable outlet nozzle.

Written by Karol Placha Hetman