Kraków 2022-12-08

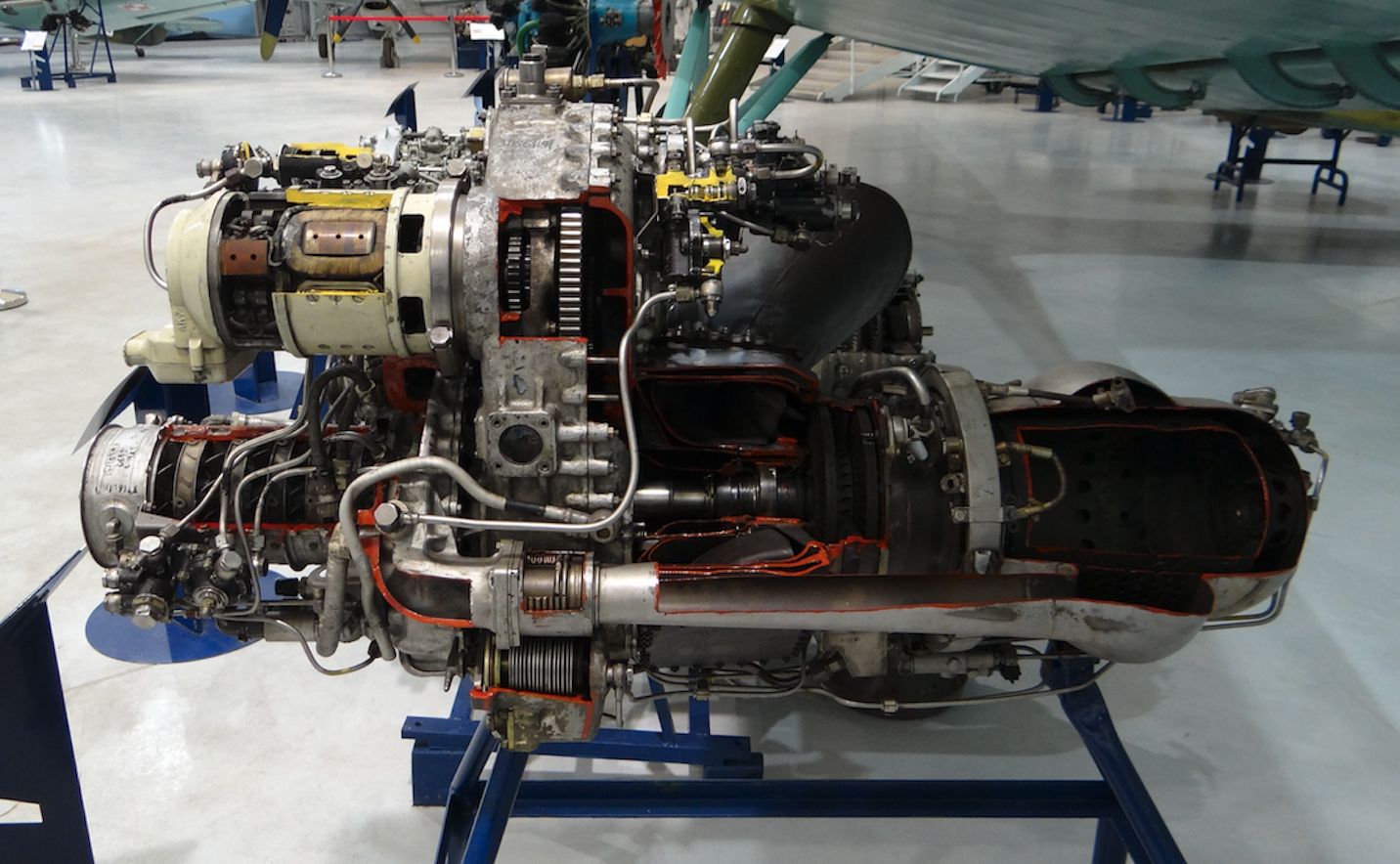

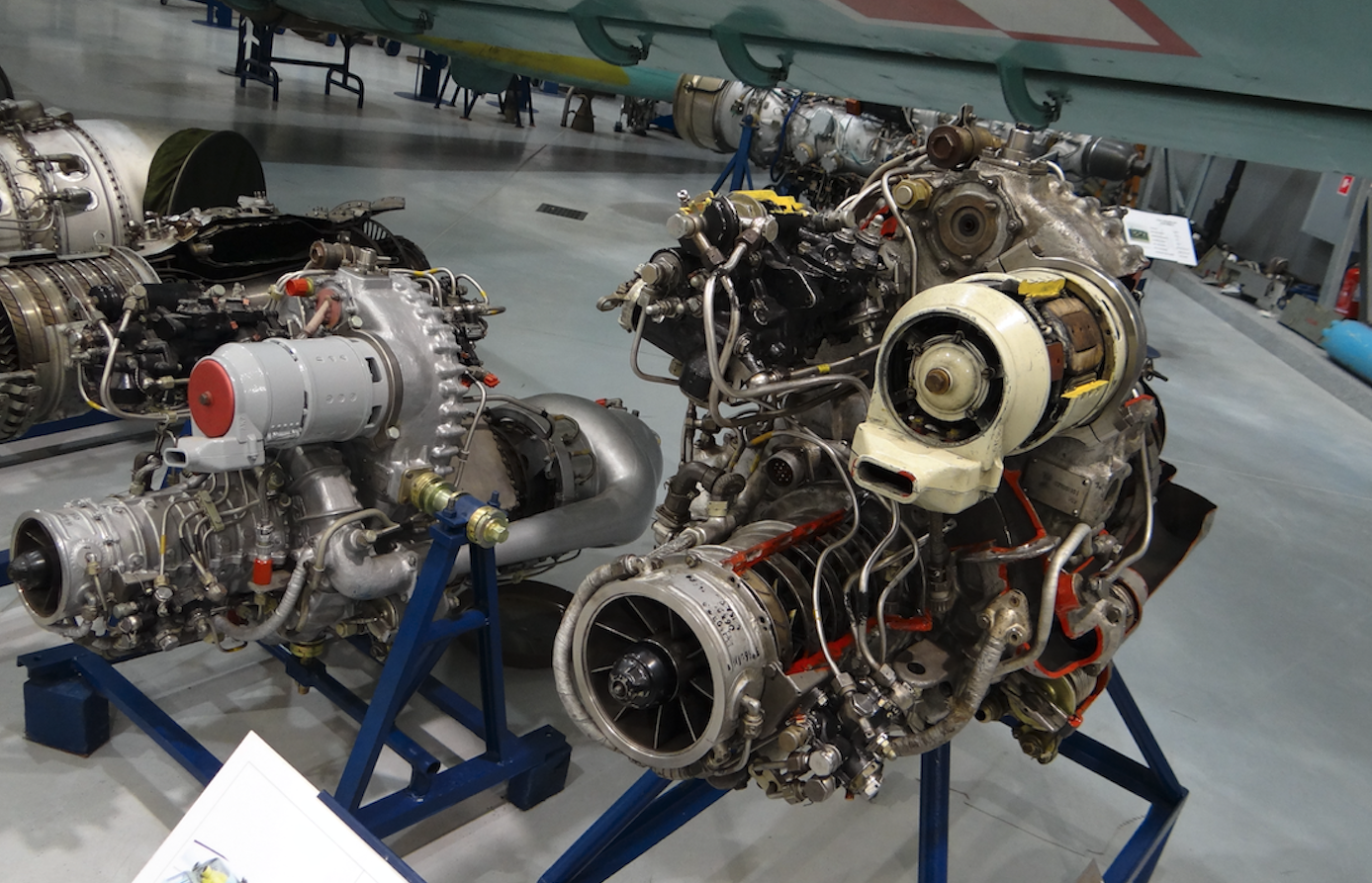

PZL GTD-350 turbine engine to power the PZL Mi-2 helicopter.

The Soviet Mil Mi-1 and Mil Mi-4 helicopters were powered by piston engines. Turbine engines have already been widely introduced in the West. Muscovites had great difficulties with developing their own turbine engines for helicopter propulsion. They illegally managed to obtain the American Allison 250 engine. On its basis, the team of engineer Sergei Izotov developed their own engine, which was marked GTD-350. The first start of the engine took place in 1961. The engine in the assembly of two copies was used in the Mi-2 helicopter. Since the processing capacity in the CCCP economy was insufficient, an agreement was concluded in 1966 for the license production of GTD-350 engines at the PZL WSK Rzeszów plant. It was even more expedient that the entire production of Mi-2 helicopters was placed in Poland at PZL Świdnik. Over 10,000 GTD-350 engines were built in Poland, and nearly 1,000 were built in CCCP.

The GTD-350 turbine engine is designed to work in the twin-engine propulsion system of the PZL Mi-2 helicopter.

The first versions of the GTD-350 engine had a service life between overhauls of only 200 hours. At that time, the service life of the Mil Mi-2 helicopter was 1,000 hours. Engineers from PZL WSK Rzeszów introduced many significant modifications to extend the engine’s service life. We managed to extend the service life of the engine to 1,000 hours.

The motor consists of a 7-stage axial compressor and one radial (centrifugal) stage. Two air ducts lead compressed air to a single canned combustion chamber at the rear of the engine. The combustion chamber is partially reverse flow, a design developed by Frank Whittle. Fuel to the combustion chamber is supplied by two injectors; one working, located in the center and one ignition located slightly to the side, integrated with the spark plug. The compressor is driven by a single turbine. Another slow 2-stage turbine powers the main gearbox. The engine has four exhaust openings, two on the left and two on the right. But only two holes are used. If the engine is mounted on the left side, the outlets on the right are plugged and vice versa. Take-off power is 313 kW (425 hp), nominal power is 235 kW (329 hp). The rotational speed of the compressor is 45,000 rpm. The rotational speed of the power turbine is 24,000 rpm. The engine output speed is 5,904 rpm. Fuel consumption at take-off is 0.496 kg/kWh. Electric engine start with a current-starter.

The power from the engines is transferred through the W2 type main gearbox common for two engines to the main rotor receiving power directly from the main gearbox. The drive to the tail rotor is also derived from the main gear, through the intermediate and rear gears, and to the helicopter aggregates.

The GTD-350 engine was produced in several versions: GTD-350, GTD-350P, GTD-350W, GTD-350W2. The engines differed in modifications and materials used. GTD-350 engines produced in Rzeszów turned out to be very durable and low failure rate. Unfortunately, the contract concluded with the CCCP did not allow the engine to be modified to be used in other aircraft structures. But let’s remember that already in 1961, the GTD-350 engine was structurally outdated and relatively fuel-intensive. The engine consumed 100 liters of aviation kerosene per hour of operation under nominal parameters.

Data T-T PZL GTD-350:

Length 1.35 m. Width 0.52 m. Height 0.68 m. Weight 135 kg. The engine has a power of 294 kW. Take-off power is 313 kW (425 hp), nominal power is 235 kW (329 hp). The rotational speed of the compressor is 45,000 rpm. The rotational speed of the power turbine is 24,000 rpm. The engine output speed is 5,904 rpm. Fuel consumption at take-off is 0.496 kg/kWh. The exhaust gas temperature in front of the turbine is 970 degrees Celsius.

Written by Karol Placha Hetman