Warszawa 2017-01-02

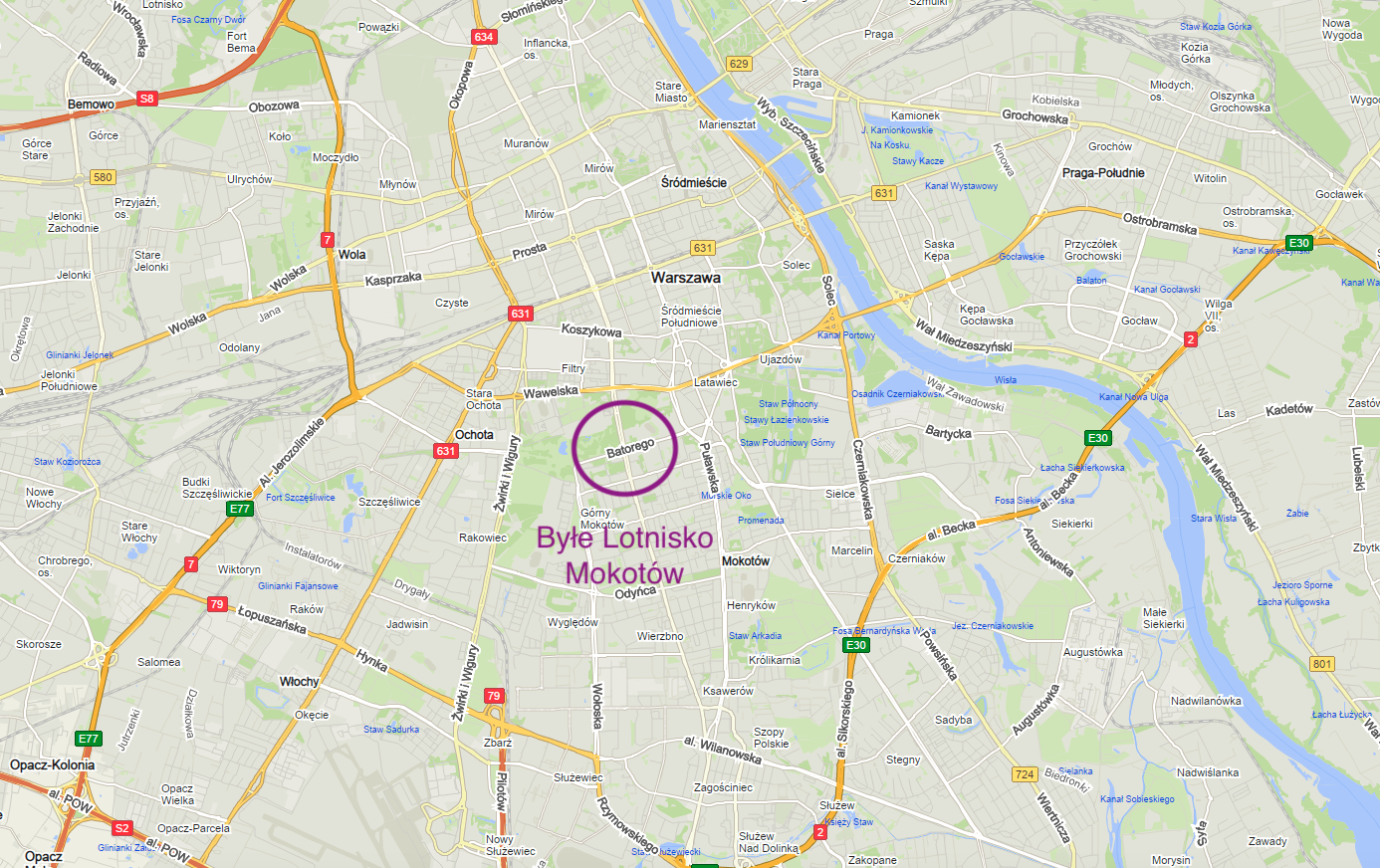

Former Mokotów Airport – Pole Mokotowskie.

Geographic coordinates: 52.211N 21.008E. Elevation 110 m.

Mokotów Airport in the Second Polish Republic.

In the 1920s, Mokotów Airport developed dynamically, although it was a provisional development. It sounds a bit strange, but already in 1920 it was known that the Mokotów Airport was hindering the development of Warsaw. Tall buildings were being built closer and closer to the airport. In 1932, the following nearby terrain obstacles were reported to impede the use of the takeoff field; On the north side, high urban buildings, tall trees about 20 m, the chimney of the University of Technology 34 m high. On the east side, two church towers 63 m high, tall houses, tall trees on the border of the airport, poplars about 20 m high. On the south side houses and a radio mast 75 m high.

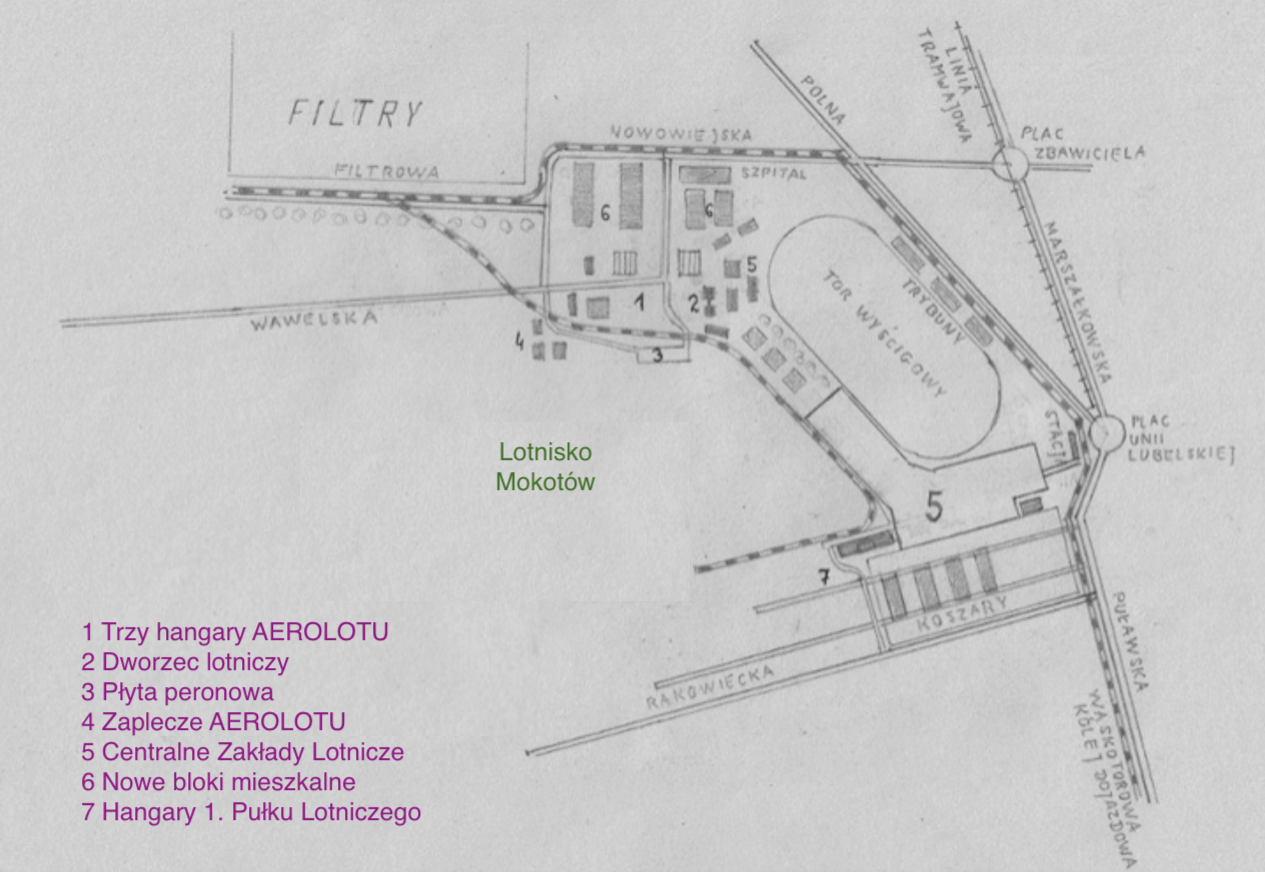

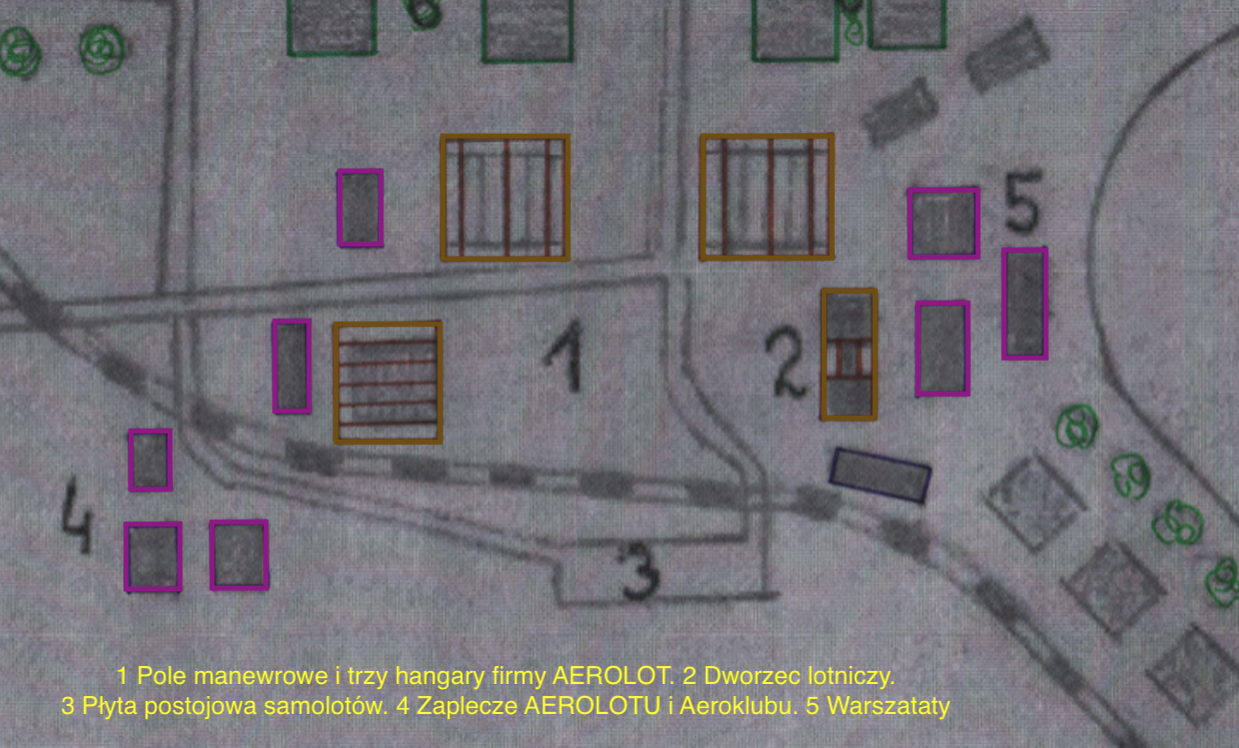

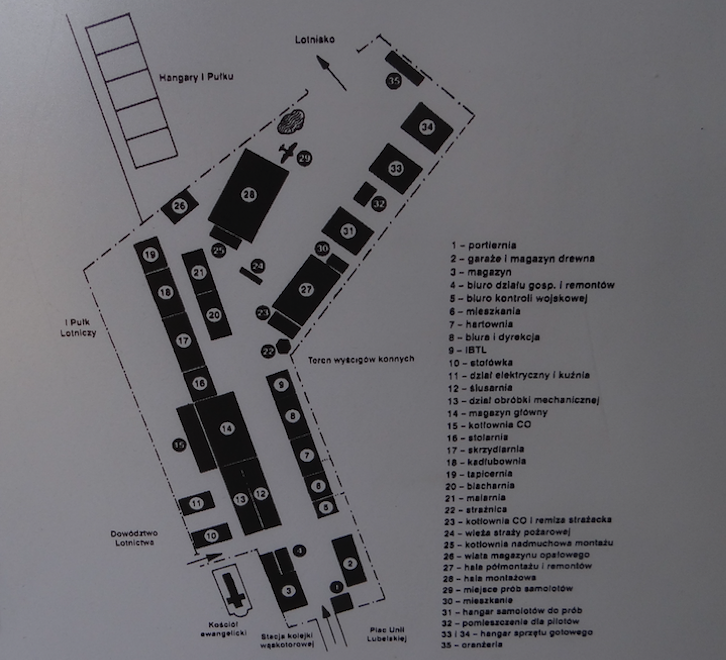

The Central Aviation Workshops (Centralne Zakłady Lotnicze) operating at the airport also developed. More renovation and production departments were established. The plants developed their infrastructure. New production facilities were built. The factory had its own water supply network, with a water tower. There was a power plant generating 120 V electricity. The plant had hangars, assembly halls and warehouses. In total, there were over 30 construction objects. Some of the internal roads were already paved.

The co-user of the airport was the Polish aviation company Aerolot. It had three large hangars and extensive facilities. The largest hangar had a door width of 29 m and a height of 4.20 m. Warsaw Airport, as Pole Mokotowskie was then called, had an airport station opened in the spring of 1922, in the form of a three-part, two-story building with a wooden structure on a brick foundation, located near the Aerolot hangars. A hardened aircraft parking area was located nearby. There was a ticket office, a waiting room, a restaurant, a post office, a telephone, a telegraph, a police station, a customs office, a meteorological station and a medical aid point. The tram stop and taxi and horse-drawn carriage rank were only 400 m away.

Basic data of the Mokotów Airport in 1932.

Basic data of the Mokotów Airport (1932). Geographic coordinates: latitude 52 degrees 13 minutes, longitude 21 degrees 00 minutes. Height above sea level: 111 m. Magnetic slope -1 degree 36 minutes. In the middle of the take-off field, a white circle with the inscription Warsaw. Landing direction indicator; inlaid white letter T. 7 pieces of wind sleeves. At night, orientation according to white obstacle lights placed on buildings surrounding the flight field. On the take-off field itself, there is a white arrow made of lanterns, indicating the landing direction. The ascent field measures NW-SE – 470 m (smallest), W-E – 1,550 m (largest). Clay surface covered with turf. The 5 kW radio station operated at the following frequencies: 900, 1,210, 1,235, 1,316 Hz. Call signs: SRM, SRN, SRO, SRP.

For 21 years, Mokotów Airport was a military, communication, sports, factory, experimental and sanitary airport. Urban layout plans for Warsaw include the liquidation of the Mokotów Airport. The general plan envisaged the construction of three new airports: a communication airport in Gocławek, a sports airport in Bielany and a military airport in Okęcie. Life verified these plans.

At the Airport, the former military road was named Wawelska after regaining independence, remained undeveloped and constituted the northern border of the Airport. For the proper functioning of the airport, a railway siding was built from the narrow-gauge railway. At Topolowa Street, within the boundaries of Pole Mokotowskie, in the period 1923 – 1925, 3-4-story apartment blocks of the Prosecutors and Judges Housing Cooperative were built. A housing estate of about 100 single-family houses was built nearby. In turn, at Rakowicka Street, in the period 1925 – 1930, the old barracks were rebuilt, where the 1st Aviation Regiment was stationed, and years later the Geological Institute was established. A little further, to the west, the building of the School of Commerce and the Warsaw University of Life Sciences were built.

In the first years of the development of Polish airports, French experiences and plans were used. The size of the take-off field met the standards, but the landing approaches (except for the western one) were far from safety standards. On the other hand, the noise of aircraft did not create good living conditions for residents.

In 1934, construction of the Warsaw transit route in the N-S direction was resumed. A wide, two-lane route was then built through Pole Mokotowskie, named Aleja Niepodległości. It divided the field, but the eastern and western parts. It was a time when the Okęcie Airport was already operating. The eastern part was unsuitable for air operations. Before the development plan began, unplanned allotment gardens were created here. The western part was suitable for air operations. More open terrain increased flight safety, especially since traffic decreased significantly. According to international regulations, appropriate lighting had to be installed for night flights. However, numerous city lights would make these navigation aids difficult to see and could even lead to disasters due to mistakes. Therefore, organic flights are limited to daytime flights only.

After 1934, the Mokotów Airport was used by sports and medical aviation. The pace of construction works near the airport slowed down because they were waiting for the Bielany Airport to be put into operation, which was supposed to take place by 1940.

When writing about Mokotów Airport, it is difficult not to mention the organizational structures of Polish Aviation in the Independent Republic of Poland. Established on November 18, 1918, the Aerial Navigation Section at the Ministry of Military Affairs had its first headquarters in the former tsarist barracks. Later it was moved to a new building in the same area, at 6 Puławska Street. Despite several name changes, the Polish aviation administration operated here until September 6, 1939.

Central Aviation Workshops and Central Aviation Works.

Right after Poland regained independence, in November 1918, in Warsaw, thanks to the decision of the Polish Army headquarters, Military Aviation Workshops were established. The plant was located in buildings in Mokotów at ul. Topolowa and Puławska 2 (currently the street is still called Puławska), next to the temple, which was then a military Orthodox church. Before the Great World War, these facilities belonged to the Awiata company and were part of the airport in Mokotów.

Initially, the Military Aviation Workshops had only two hangars. Over time, the number of renovated or newly built facilities increased. There were about 30 pieces in total. The workshops had: a power plant, ammunition storage, fuel tanks, garages and a railway siding.

The main task of the workshops, in the first period of their operation, was the renovation of aircraft left behind by the warring parties and machines imported by Polish aviation units established in Western Europe. Although the workshops were repair plants, they played an important role in the creation of the Polish Aviation Industry.

Already on December 20, 1918, a decision was made to change the name of the plant to Centralne Warsztaty Lotnicze (CWL). It was headed by lieutenant engineer Michał Tłuchowski, who was one of the members of the Aerial Navigation Section established at the Ministry of Military Affairs. A significant part of the CWL staff were Poles who received education from the partitioners during the Great World War. The number of employees was growing rapidly. Already in January 1919, the plant employed over 200 workers, and two years later their number reached approximately one thousand people. In the following years, the number of employees fluctuated between 450-550 people. This increase in the number of employees in the period 1919-1920 resulted from the ongoing war with Bolshevik (Soviet) Russia, when the plant worked with double strength for the needs of the Polish Army.

The Central Aviation Workshops inherited the machinery and tools from the invaders. The machine tools came from German and Austrian factories. New machine tools were delivered from the USA in the second half of 1919, as part of the assistance of the American administration in the fight against Bolshevik Russia (Moscow state). Materials, raw materials and spare parts were imported from France, Austria and the Czech Republic. Later, deliveries arrived from Italy and the USA.

The plant initially focused on repairing planes left by the Germans. Most of them were very worn-out and damaged planes. Some machines could no longer be repaired and were used as a source of spare parts. Particularly valuable were aircraft engines, which were not produced in the partitioned territories, and in free Poland we still had to wait for an engine factory. It should be remembered that the aviation industry developed much faster in countries that already had a car industry and produced combustion engines, such as England and France.

On November 20, 1918, pilot second lieutenant Jakubowski made the first flight on a renovated military aircraft of Albatros Flugzeug-Werke G.m.b.H Albatros C-III, which was considered the first flight over Warsaw of a Polish aircraft. The prototype Albatros C aircraft was built in 1915, and the development Albatros D was built in 1917, but by the end of 1918, they were already obsolete. Albatros planes were also called "OEFFAG" because they were manufactured in Austria-Hungary at the Oesterreichische Flugzeugfabrik A.G. plant. The Polish Army had a total of about 50 Albatros C/D aircraft of various versions. All of them were renovated at the Central Aviation Workshops.

Albatros Flugzeug-Werke G.m.b.H Albatros C/D. reconnaissance and fighter aircraft. Wooden structure with metal elements, biplane system, covered with plywood and canvas, fixed chassis. Basic data (version D in brackets): span 11.69 m (9.05 m), length 8.00 m (7.33 m), height 3.10 m (2.98 m), empty weight 850 kg ( 660 kg), total weight 1,380 kg (900 kg), speed 170 km/h (175 km/h), range 400 km (250 km), flight time 3 hours. (2 hours.). 150 HP (160 PS) inline engine. Armament: 2 machine guns.

Very quickly, three basic departments were established in the plant: the airframe repair department, the engine repair department and the propeller construction department. It should be remembered that propellers cannot be repaired once they are damaged and their production was very important. In 1919, CWL renovated over 200 aircraft, over 150 engines and produced over 150 propellers. The very next year (1920), over 300 planes, over 250 engines were renovated and nearly 400 propellers were built. The situation was not made easier by the large number of types and versions of aircraft that Poland acquired from various countries: Italian (Ansaldo A-1 Balilla), French (Breguet XIV, SPAD 13.CI), British (Bristol F.2B Fighter, De Havilland DH-9). ), Dutch (Fokker D.VII), German (Hannover CL-II, Albatros C/D, LVG C.V, AEG C.IV). In addition to renovations, the plants assembled aircraft purchased in France, Great Britain and Italy.

From 1923, the Central Aviation Workshops fully satisfied the needs of the Polish Army and it was possible to afford to sell renovated aircraft abroad. For example, 10 refurbished De Havilland DH-9 aircraft were sold to Latvia.

Already in November 1918, the Central Aviation Workshops, in addition to carrying out renovations, were tasked with starting the production of an aircraft type that had already been proven in combat. Among the various post-German machines in Poland there were several reconnaissance and attack two-seater Hannover CL-II planes, designed by the pioneer of German aviation, Hermann Dornier. In the spring of 1919, several copies of these aircraft were equipped with universal engine beds according to the native design of engineer Eberman. In April 1919, a decision was made to start serial production of this aircraft at the Central Aviation Workshops. In the design office, technical documentation was prepared and templates and dies were made, and preparations for series production were made in one of the halls. The entire program was headed by one of the managers of the CWL plant, lieutenant engineer Karol Słowik. It was expected that approximately 45 machines would be produced. Materials were collected to build 10 units. The first three planes began to be built in May 1919. The aircraft was marked CWL series 18, and the prototype CLW 18.01. In the literature on the subject, the designations CWL Słowik or CWL SK-1 (Słowik Karol) are also found. The first flight took place on August 8, 1919. On August 23, 1919, the plane was to be demonstrated to the Chief of State, Marshal Józef Piłsudski. Unfortunately, a tragedy occurred. During the flight, the wings broke and the plane and the crew fell to the ground. Both pilots died: Lieutenant Karol Słowik and Pilot Second Lieutenant Kazimierz Jesionowski. As it turned out, the plane received a more powerful and heavier engine, and the airframe was not reinforced. All that was needed was to use stronger lashings between the wings. Further production was suspended. The completed second prototype was intended for endurance tests.

Hannover CL-II / CWL Słowik. Basic data: reconnaissance and attack aircraft, 2-seater, biplane, mixed construction with predominance of wood. Dimensions: span 11.80 m, length 7.80 m, height 2.80 m, empty weight 742 kg, take-off weight 1080 kg, max speed 165 km/h, range 420 km, flight time 2.5 h. Armament 1 rifle operated by a pilot and 1 rifle operated by an observer.

In the spring of 1920, CWL began the production of the WZ-VIII De-Że-Pe airliner, designed by engineer Władysław Zalewski. The abbreviation De-Że-Pe stood for the Department of Air Navigation. Władysław Zalewski was one of the Polish pioneers of aviation structures. In the period 1912-1937, he developed about fifteen of his own glider and airplane designs. After the Great World War, at the end of 1918, he was employed at CWL as the head of the design office. The WZ-VIII aircraft was the seventh construction of Władysław Zalewski, and the first Polish construction in the Second Polish Republic. Due to the ongoing war, work on the plane progressed slowly. Just before the construction of the WZ-VIII De-Że-Pe prototype was completed, in August 1920, it was accidentally damaged and remained in the hangar. In July 1922, Władysław Zalewski asked the CWL management to complete the construction. Consent was granted only at the turn of 1923/1924. However, the designer had to make many modifications and changed the aircraft’s designation to WZ-VIII bis. But already in the spring of 1924, Władysław Zalewski received an offer to take over the design office at the Wielkopolska Wytwórnia Samolotów "Samolot" in Poznań. The plane was not completed and the construction was considered no longer viable.

WZ-VIII De-Że-Pe / WZ-VIII bis. Basic data: airliner, 2-seater, biplane, mixed construction with predominance of wood. Dimensions: span 12.00 m, length 8.10 m, height 3.10 m, empty weight 1200 kg, take-off weight 1800 kg. Rolls-Royce Eagle government engine with a power of 265 kW (360 hp). Armament: 1 rifle operated by the pilot and 1 rifle operated by the observer.

From 1922, students of the Aviation Section of the Warsaw University of Technology used the CWL plant to build the SL-1 "Akar" glider. In 1924, the SL-2 "Czarny Kot" and SL-3 gliders were created. Later, the cooperation was interrupted due to differences between the aviation authorities, CWL management and students.

After all border conflicts were resolved in 1922, it was noticed that building our own arms industry was not only necessary, but also very urgent. Therefore, the Polish government has made efforts to launch serial production of aircraft in order to become independent from foreign suppliers. Since the first attempts to build a Polish aircraft and launch its serial production turned out to be unsuccessful, an offer of a license for the production of an appropriate aircraft was sought. From France we received Potez XV A2 airliners and Hanriot HD-14 training aircraft as well as the rights to license these machines. The future aircraft manufacturer in Poland was to be a Polish-French company called Spółka Akcyjna Francusko-Polskie Zakłady Samochodowe i Lotnicze Francopol, abbreviated as Francopol, often spelled Frankopol. The company was established in 1921, and its only Polish founder was the vain general Włodzimierz Zagórski. Back in 1921, the Ministry of Military Affairs concluded an agreement with a company that undertook the production of several thousand airplanes and aircraft engines. The construction of the factory, which was built in Okęcie and Raków, soon began. For various reasons, mainly political and financial, the construction of the plant was delayed and the company did not keep the concluded contract. Despite the advance payment and favorable terms of the contract, the company only managed to build two small and poorly equipped buildings. These facilities were not suitable for airframe production. Therefore, at the beginning of 1925, the Ministry of Military Affairs terminated the contract with the Francopol company.

It is worth knowing that in the first years of our independence, France provided Poland with significant financial assistance for the modernization of aviation, provided that the planes were purchased in France. Large-scale aircraft purchases in France meant that around 1925, Polish Aviation was one of the strongest in Europe in terms of the number of equipment it had. However, while some of the purchased machines were of a good design standard, e.g.; Breguet XIX or Potez XXV, others had an incorrect design and were bad. The Farman F-68 had very poor performance. The dangerous one was the Blériot SPAD S-61, known for numerous accidents and the death of 31 pilots. But at the same time there were insufficient trained pilots. So the strength of the Polish Military Aviation was illusory.

The failed attempt to establish a Francopol aircraft factory forced the heads of the Aviation Department of the Ministry of Military Affairs to make organizational reforms. There were staff transfers, and the Central Aviation Workshops were transformed into the Central Aviation Works. Its structures included not only the facilities at the Mokotowskie airport, but also the newly constructed facilities at the future Okęcie airport. Funding changes have also been made to prevent possible abuses. As a result, Potez XV A2 planes were produced in Lublin, and Hanriot HD-14 (H-28) planes in Poznań, which will be discussed in the next chapter.

At the Central Aviation Works in the period 1925-1927, several Potez XV, Breguet XIV and Farman F-68 "Goliath" aircraft were converted into forest dusting aircraft. The entire action was related to the fight against pests that, having no natural enemies in the forest environment, caused considerable havoc in the forests.

One of the planes renovated at the Central Aviation Workshops was the French Breguet XIX (Br.19). It was a very modern French aircraft, 250 of which were purchased for the Polish Army in 1925-1930. The planes were built in the A2 (linear, 2-seater) and B2 (light bomber, 2-seater) versions. The Breguet XIX (Br.19) aircraft was developed on the basis of the successful Breguet XIV and first flew in March 1922. The plane was powered by a government Renault 12Kb engine with a power of 450 HP. Later, engines from other manufacturers were installed. The prototype reached a speed that was 20-30 km/h higher than its competitors. It was not a stunning advantage, but its construction was an unrivaled example of lightness of construction, which resulted in the machine being used both in the army and in sports aviation, participating in rallies in many countries. To compare with the Potez XV aircraft, the Breguet XIX liner had an empty weight of 150 kg and carried 200 kg more payload. Moreover, the metal structure was more durable than the wooden one. Large-scale production started in 1924, and Poland was one of the first recipients. There were plans to purchase a license to produce Breguet XIX aircraft in Poland, but they were not finalized.

The airframe structure was metal, made of duralumin. The hull was made of a metal truss covered with sheet metal and canvas at the rear. Metal wings covered with sheet metal and fabric. Renovations of Breguet XIX (Br.19) aircraft at the Central Aviation Works allowed for mastering the principles of building modern duralumin aircraft structures, which in the future resulted in successful Polish PZL P.7 / P.11 structures.

Breguet XIX (Br.19). Basic data: Dimensions, span 14.80 m, length 9.50 m, height 3.40 m, empty weight 1390 kg, take-off weight 2500 kg, max speed 230 km/h, range 800 km (sports versions could have a range of over 9000 km). 450 HP engine. Armament: 1-2 machine guns, up to 400 kg of bombs.

In the period 1925-1927, two planes were built at CZL: D-1 Cykacz and Skraba ST-3, which were amateur designs. The D-1 Cykacz sports plane was developed and built by Jerzy Dąbrowski, a student of the Warsaw University of Technology, and later the creator of the famous PZL.37 Łoś bomber. The D-1 Cykacz plane was first flown at Pole Mokotowskie on February 25, 1925. The wooden biplane plane was tiny. Span of only 5.00 m, length 3.70 m, total weight 225 kg. Equipped with a 12 kW Blackburne Tomtit engine. Still, the plane flew and was beautifully made. The Skraba ST-3 aircraft was built in a similar arrangement. A bit larger than the D-1 Cykacz. Span approximately 8.00 m, length approximately 5.50 m. Anzani radial engine with a power of 33 kW (45 HP). Total weight approximately 450 kg. The Skraba ST-3 plane was designed and built by pilot engineer Bolesław Skarba, who was the assembly manager at CZL. The plane first flew in July 1927, and the tester was the designer himself. It was the first Polish all-metal structure, modeled on the structure of French Breguet XIX aircraft renovated at CZL. The hull structure is made of duralumin pipes and welded steel joints. The whole thing was covered with sheet metal, and the rear of the fuselage and most of the wing surfaces were covered with canvas. The D-1 Cykacz and Skraba ST-3 planes were considered amateur and sports designs, good in piloting, although with poor performance. However, they allowed CZL designers to gain experience, which resulted in successful aircraft designs in the future.

In 1926, another attempt was made to implement the serial production of an airliner designed by engineer Władysław Zalewski. This time it was an airliner marked WZ-X, which was built at CZL in Warsaw. On August 23, 1926, the prototype made its first flight at the Mokotów airport. The plane turned out to be correct and the decision was made to build four prototypes for endurance and flight tests. Comparative tests with French structures showed good performance of the Polish structure. The Department of Aviation considered the possibility of starting mass production, but due to the purchase of a large number of Potez XXV and Breguet XIX aircraft, production was not undertaken. The already built units were transferred to schools in Dęblin and Bydgoszcz and were used until the mid-1930s.

CZL WZ-X airliner. Basic data: 2-seat biplane, wooden structure covered with plywood and canvas, dimensions, wingspan 11.31 m, length 8.21 m, height 3.07 m, empty weight 1246 kg, total weight 1915 kg, max speed 205 km/h , range 800 km. Armament: 2 fixed guns and 2 movable guns. Lorraine-Dietrich LD-12 Eb engine with a power of 331 kW (450 HP).

An important role in the history of Central Aviation Works was played by the French Blériot SPAD S-61 C1 fighter aircraft (SPAD stands for the French abbreviation Societe pour l’Aviation et ses Derives – Aviation Association and its derivatives. C1 means single-seat fighter). The plane was built in 1923 at the French Blériot Aéronautique factory in Suresnes and first flown on November 6, 1923. The plane’s designer was André Herbemont. This aircraft was an export version of the Blériot SPAD 81 C1 design, which was the basic type of fighter in France. According to military plans, Poland needed 300 fighter planes. In 1925, the Air Navigation Department of the Ministry of Military Affairs purchased 250 of these machines and 50 Blériot SPAD 51 C1 machines, which were ordered in batches. Despite the noticed design errors, the deliveries were completed and a license was also purchased. The French-built aircraft were delivered between September 1925 and December 1926.

The Blériot SPAD S-61 C1 plane was difficult to fly for inexperienced pilots, which is why there were several accidents and disasters. The plane easily entered a flat spin from which it was difficult to recover. The machine was even labeled as a flying coffin. However, experienced pilots liked this machine and gave it a good rating. They said the plane was happy to follow the controls. It was good at higher pilotage figures, which made it easy to exceed the permissible overloads, which led to the wings breaking off several times, resulting in a catastrophe. There were opinions that the planes in France were built of second-class materials, even though the production was supervised by engineer Ryszard Bartel. The Polish Army requested the manufacturer to make corrections. The Blériot plant completed the task and sent the appropriate documentation. In this way, many design errors were eliminated, such as the fuel system. However, it was not possible to increase the strength of the airframe.

The Blériot SPAD S-61 C1 aircraft was to be produced by Francopol, which managed to build only a few unfinished fuselages. Ultimately, the production was taken over by Centralne Zakłady Lotnicze. The plane was produced from 1926, only at a rate of about 10 machines per year, and by the end of 1929, only 30 planes were built, possibly marked PZL SPAD 61 C1. In total, 280 Blériot SPAD S-61 C1 machines were used in the Polish Army.

By the end of January 1929, there were several accidents of Blériot SPAD S-61 C1 aircraft. A regulation was introduced to limit the overloads caused during maneuvers. The airframe structure was suspected to be too weak. Therefore, tests were carried out on two machines built in France and one machine built in CZL. The tests showed the poor design of the French machines. In February 1929, Colonel Ludomił Rayski issued an order banning acrobatics on the Blériot SPAD S-61 C1 aircraft and obliged pilots to use parachutes. Already at the end of 1929, planes began to be transferred from fighter squadrons to training and auxiliary aviation. The problem was dealt with by engineer Zbigniew Elczanowski from CZL. He developed methods of strengthening the weakest places in the airframe, which turned out to be expensive to implement and did not guarantee the expected effect. When testing stronger lashings, the spars were deformed and the plane lost its good aerodynamic characteristics.

Despite general problems with the strength of the airframe, Capt. Pilot Bolesław Stachoń on the Blériot SPAD S-61-4 plane on April 5, 1926, achieved the Polish record for the time to climb to a ceiling of 6,000 m. Already on July 26, 1926, this record was improved by Eng. pilot Jerzy Widawski, who later achieved two other records on this plane. Airplanes were quickly transferred from combat units to auxiliary and training aviation. Already in 1931, 80 Blériot SPAD S-61 C1 machines were removed from the state and dismantled. The engines were used in other aircraft. In 1932, only a few copies remained.

Blériot SPAD S-61 C1 fighter aircraft. Basic data: 1-seat biplane, mixed construction with predominance of wood, plywood and canvas covering, dimensions, wingspan 9.57 m, length 7.00 m, height 2.90 m, empty weight 1055 kg, total weight 1565 kg, max speed 227 km/h, range 800 km. Armament: 2 7.70 mm fixed synchronized machine guns. In Poland, planes were equipped with bomb launchers weighing 12.5 kg. Lorraine-Dietrich LD-12 EW engine with a power of 331 kW (450 HP). The planes were equipped with: an F-26 camera, a photo gun, and an oxygen installation.

The Blériot SPAD S-61 C1 had a twin in the form of the Blériot SPAD S-51 C1 fighter (designation C1 – single-seat fighter). The plane first flew on April 16, 1924, half a year after the S-61 variant. The contract for the purchase of fighters for the Polish Army was changed from 300 S-61 fighters to 250 S-61 and 50 S-51 fighters. The Blériot SPAD S-51 C1 aircraft had a different drive. Instead of the commonly used liquid-cooled in-line piston engine, an air-cooled radial engine was installed. It was a big change at the time, almost revolutionary. The radial engine had several significant advantages. It was lighter than an inline engine. It was easier to build and therefore easier to repair and inspect. There is no cooling installation. At the same time, its standard service was much shorter. He achieved the appropriate operating temperature much faster. Required less oil and grease. It used less fuel. The radial engine housing was equipped with movable shutters, which the pilot used to regulate the temperature of the power unit. The development of high-power radial engines was possible thanks to the development of metallurgy and the development of new metal alloys. Interestingly, radial engines turned out to be much more resistant to damage caused by rifle bullets. There were cases when the radial engine operated with one cylinder broken.

The Blériot SPAD S-51 C1 planes were as defective as the Blériot SPAD S-61 C1 machines in terms of airframe. There were fewer accidents on them just because there were five times fewer of them. Most pilots saved themselves by using parachutes, which were already mandatory if the pilot was performing aerobatics. Five pilots were killed. The planes enjoyed a better reputation, but mainly due to the powerplant used. Blériot SPAD S-51 C1 aircraft were in use until 1933. These planes allowed us to gain experience in operating radial engines. We learned how to repair this type of drives and prepared their future production in the country.

The Blériot SPAD S-51 C1 and Blériot SPAD S-61 C1 aircraft were the last fighter aircraft purchased from France. They were replaced by planes manufactured entirely in Polish plants: Podlaska Wytwórnia Samolotów PWS-10 and built under the PWS-A license.

Blériot SPAD S-51 C1 fighter aircraft. Basic data: 1-seat biplane, mixed construction with predominance of wood, plywood and canvas covering, dimensions: wingspan 9.47 m, length 6.45 m, height 3.10 m, empty weight 990 kg, total weight 1360 kg, max speed 230 km/h, range 680 km. Armament: 2 7.70 mm fixed synchronized machine guns. Gnome-Rhone "Jupiter" series IV type 9 Ab radial engine with a power of 309 kW (420 HP). The planes were equipped with: an F-26 camera, a photo gun, and an oxygen installation.

During the discussed period of aviation history, the basic design of the aircraft was developed. The classic arrangement was a biplane with a fuselage ending with a single vertical tail, divided into a stabilizer and rudder, and a two-part horizontal tail, also divided into a stabilizer and a rudder. The rudders were moved using cables. The crews consisted of one or two pilots who sat in open cockpits. Interestingly, there was no floor in the cockpits because it was unnecessary. The pilot’s legs rested on the pedals of the T-bar. The engine was placed in the front of the fuselage and equipped with a pulling, fixed propeller. In-line combustion engines were standardly used, with power ranging from 150 HP to 450 HP. The fuel was placed in two tanks. Mainly in the fuselage and a small spare tank often located in the structure of the upper wing. This tank provided an engine operating time of 10-15 minutes, which allowed finding the best place for an emergency landing.

For 20 years, the basic raw material for building airplanes was wood. As a raw material, it was cheap, and its strength was comparable to modern steel. Wood is easy to work with and relatively simple tools were sufficient. But wood also has disadvantages. Its structure is heterogeneous, so timber with dense grain was sought. The most serious disadvantage of wood is its water absorption, which leads to rotting and turning into rot. There was never a shortage of wood in Poland and it was of very good quality. Coniferous trees were mainly used, with pine being the dominant one. Wood in the form of sawn timber was transported to the mills in Pole Mokotowskie by rail from sawmills near Warsaw. The lumber was placed in storage or placed in a drying kiln to remove excess moisture. Wood intended for production was subjected to compressive, tensile, bending and torsion strength tests. The main woodworking took place in the carpentry shop. Here, individual supporting elements of the wings and fuselage were made according to patterns and templates. Already then, technologies were used in which glued scantlings were used to make some elements. An element made using this technology did not twist (warp) over time.

The fuselage was made of several frames and stringers. After they were connected using gluing methods and metal fittings, they were impregnated several times to extend their service life. Although there is no doubt that it was extremely rare for planes made this way to be five or more years old. Part of the hull was covered with plywood. The back part was covered with canvas. In another carpentry shop, wings were made, which, just like today, consisted of spars and ribs. The leading edge was covered with plywood. Most of the panel’s surface was covered with canvas. Everything was impregnated and painted. Painting not only gave the planes an aesthetic appearance, but above all protected the machines against bad weather conditions.

It is worth mentioning here the specialists who were employed in the construction of aircraft. The carpentry shop was mainly staffed by furniture carpenters who had acquired their skills in furniture-producing plants and workshops. They knew wood technology, its processing, and methods of impregnation and painting very well. Aircraft factories also employed tailors and seamstresses, because an average airplane used over 50 m2 of cotton canvas. This canvas had to be cut according to forms and sewn together appropriately. Then apply separately to the fuselage and wings. Cotton canvas is a relatively good material. Strong enough and paintable. The disadvantage is that they only take the shape of the skeleton on which they are placed. And of course they can be easily damaged. Cotton cloth was brought to the plant from nearby factories in Łódź.

Other professionals employed in aviation plants included locksmiths, blacksmiths and mechanics. Locksmiths made and installed various types of fittings. Blacksmiths made engine beds, i.e. elements that connected the engine with the first frame, the power frame of the hull. They also did chassis shaving. Mechanics in the assembly hall assembled all the components into one whole, which resulted in an aeroplane, i.e. an airplane. The plants also employed rare professionals, such as piano and upright piano tuners. For what purpose? The airfoil structure between the upper and lower wings was stiffened with lashings in the form of cables or steel tapes. Their proper tension was extremely important. He couldn’t be too strong or too weak. And this task was handled by tuners who adjusted the tension of the string based on the sound made by the guy.

We used the word aeroplan above. It is worth realizing that in the 20s of the 20th century, there was a different terminology than the one in force today. The plane was called an airplane or, less commonly, a flying machine. Engine fuel was called gasoline because it gave "gas" to the engine. That’s why when we talk about cars nowadays we say "put on the gas" and not "add fuel", although that would be more logical. Natural olive oil was used for lubrication, so there was no mention of oil. The rotating propeller was called the "drive wheel" because this element gave momentum and thrust to the airplane. Machine guns mounted on planes were called "shotguns" because they threw bullets. The term airport was also not used. In the legacy of the partitioners, we had the terms airport or aerodrome. But in the aviation community, the terms field or training ground were commonly used, which is why we often encounter the name Pole Mokotowskie. In turn, the word pilot entered the Polish language very early, because the word aeronaut was not accepted.

The developing Polish Aviation Industry required modifications to the organizational structure. Centralne Zakłady Lotnicze operated as one of the state administration entities, reporting to the Department of Air Navigation. On December 21, 1927, CZL was transformed into an independent production unit and financed as an economic entity. On March 1, 1928, a company was established: Państwowe Zakłady Lotnicze, which took over all the fixed and intellectual property of Centralne Zakłady Lotnicze. Państwowe Zakłady Lotnicze are discussed in other articles.

In 1937, a great ceremony took place at the Mokotów Airport, handing over 130 planes to the Air and Gas Defense League for the training of Polish Youth.

Polish Army at Mokotów Airport.

On December 16, 1918, the first oath of Polish Soldiers took place at the Mokotów Airport.

In 1918, a pilot school was organized at the Mokotów Airport, named "Mokotów Airport Pilot School" and was the first aviation school in the Republic of Poland. It was organized by Lieutenant Colonel Łossowski and led by Lieutenant Pilot Jakubowski. The first planes were two "Brandenburg" twin-planes, acquired as an exchange from the Czyżyny-Rakowice Airport.

The school was relatively quickly renamed the "Military Aviation School". Pilots, observers, mechanics and generally air force officers (commanders) were trained. The first commandant of the school was Capt. pilot J. Malczewski. The school’s situation was very difficult. Everything was missing: planes, teaching aids, textbooks, notebooks, lecture halls, and even weapons for soldiers. Therefore, training was relatively slow. It was easier to train pilots for new flying equipment, who were already trained in the invaders’ armies, especially the Muscovites. On March 2, 1919, the "Aircraft Maintenance School" was separated from the school, which took over the training of mechanics. Lieutenant Witkowski became its commander.

On December 21, 1918, an order was issued based on which the formation of air squadrons began. They were supposed to consist of: 6 planes, 4 trucks, 2 passenger cars. The 1st intelligence squadron was formed on February 24, 1919. Its first commander was Captain Pilot Grochowski. Most of the new squadrons were formed by early May 1919. The squadrons were incomplete in terms of personnel and equipment. At the same time, aeronautical troops, i.e. observation and barrage balloon units, were created.

The aviation situation improved significantly in May 1919, when units formed in France under the command of General Józef Haller arrived in Poland, with their own air force, which included 7 squadrons, a pilot school and an air park. Each squadron consisted of: 12-15 planes, 4 trucks, 6 semi-trucks, 2 passenger cars, 8 trailers and trailers, 2 "photo" cars, 1 motorcycle, 1 bicycle, 1 field kitchen, tents. The air park had: 4 trucks, 28 semi-trucks, 3 passenger cars, 20 reserve planes, a bomb and ammunition warehouse, fuel tankers and barrels of grease and oil, a large warehouse of machines and tools, and tents. The planes arrived in Poland dismantled by trains. After assembling the planes, General Józef Haller inspected the army. Compared to the local squadrons, this army looked impressive. The blue uniform itself made me jealous. Most of the soldiers, especially among the officers, were French. The "French Pilot School" in Poland began operating on June 1, 1919. The "Officers’ School of Air Observers" was established based on the school’s staff. In January 1920, the French school was completely Polonized and received the name "Lower Pilot School in Warsaw". In April 1920, the school was moved to Dęblin. At the same time, the observer school was moved to Toruń.

The Mokotów airport quickly turned out to be too small and most of the combat squadrons were gradually transferred to other airports.

In September 1920, the Polish Military Aviation received its own corps. So far, these have been soldiers of other types of weapons. Usually infantry. In this way, military ranks associated with cavalry, such as captain, disappeared from the air force. Already in the spring of 1920, uniforms were unified. A khaki uniform was introduced for the entire Polish Army. Individual troops only had different color tabs. Aviation was given a dark yellow color. A moment later, ribbons of the same color were added to the horn and sapphire trousers with yellow stripes to the gala outfit. Another uniform reform was carried out in 1936, when the aviation uniform was given a steel color, although yellow was still considered an aviation color.

In May 1921, the Minister of Military Affairs issued a decision to begin the formation of the 1st Aviation Regiment under the command of Colonel Pilot Camillo Perini. Due to its location, the 1st Aviation Regiment was an exclusive and exemplary unit. Soldiers proudly wore the number "1" on their shoulder boards. The staff also wore a regimental badge on the left pocket of their jacket. On May 19, 1921, Colonel Perini issued the first order and this day became the regiment’s holiday. Initially, the Regiment was to consist of three Divisions. Ultimately, two Divisions were created, a fighter and an intelligence one. In October 1929, the Bomber Squadron was established, later expanded to a Division consisting of three squadrons. They were numbered 211, 212, 213, where the second digit meant the 1st Aviation Regiment.

At the end of 1930, the construction of the Okęcie Airport was so advanced that the transfer of military aviation could begin. The transfer took place in stages. At that time, the Staff Squadron was separated from the 1st Aviation Regiment. It became an independent unit and had 10 aircraft in its inventory.

Commercial aviation.

In September 1920, the first communication planes appeared at the Mokotów Airport. They belonged to the shipping company "Compagnie Franco Roumaine de Navigation Aérienne". The company extended the Paris-Strasbourg-Prague-Warsaw line. Initially, irregular courier flights with mail were operated. Regular flights began on April 12, 1921. The fleet consisted of Potez VII and Potez XI aircraft, which after modifications carried 3-5 passengers.

Then, the aviation company Aeroloyd/Aerolot visited the Mokotów Airport. It had a base at the Wrzeszcz Airport in Gdańsk and the Mokotów Airport. Here it had three large hangars. This company was nationalized in 1929 and its assets became part of the national carrier – LOT. In 1931, major pilot engineer Wacław Makowski became the director of LOT. The company then changed its name to LOT Polish Airlines (PLL LOT) and has existed under this name until now (2016). At that time, a stylized crane became the carrier’s badge. At that time, the letters in registrations also changed in aviation. In Poland, the letter "P" was replaced by the letters "SP", which is still valid until now (2016).

In 1931, the Skrzydlata Polska magazine began a campaign to replace the word "avionetka" with the Polish name "tourist plane". The action was effective until 1939.

Liquidation of Mokotów Airport.

After the relocation to Okęcie Airport of: the 1st Aviation Regiment, PZL State Aviation Works, the Airport, PLL LOT – Mokotów Airport lost its multi-character. Now it has become only a sports and sanitary airport. Of the military units, only the Staff Squadron remained, and of the aviation plants, the Glider Workshops of engineer Kocjan. The largest aviation sporting events: balloon and airplane events were still held at the Airport. The Warsaw Aero Club became the main user of the airport. Its facilities were located in the western part of Pole Mokotowskie from the south.

In 1935, an autogyro, then called an airplane without wings, was demonstrated for the first time in Poland at the Airport. The gyroplane shown was designed by the Spanish engineer Gierva and purchased by the Ministry of Communications. The pilot was Lieutenant Colonel Pilot Bolesław Stachoń.

There was a parachute tower at the Mokotów Airport for 30 years. It was 28 m high and was used by the flying club and the army. Sometimes parachute jumps were organized there for thrill seekers.

Occasional exhibitions, not only related to aviation, were organized in the former LOT Polish Airlines facilities. In 1936, in the renovated buildings of the PZL factory, the "Aviation Cadet School – Technical Group" was located. It was moved here from Toruń.

Fights for the Mokotów Airport continued during the defensive war of 1939 and during the Warsaw Uprising of 1944. After the Moscow army entered Warsaw, it turned out that the flying club’s hangar and part of the hardened PPS remained intact. Because the Okęcie Airport was in worse condition, a liaison squadron using Po-2 aircraft was placed in the former flying club facilities. The leveled take-off field had dimensions of 1,000 m x 800 m. However, rebuilding the Mokotów Airport would be irrational.

On September 2, 1945, the first post-war Aviation Festival was organized at the Airport. It aroused moderate interest among Warsaw residents. It must be remembered that the Polish nation was waiting for the arrival of the Polish Air Force from the West, just as it was with General Józef Haller’s "Blue Army". However, this did not happen. On September 7, 1947, another Aviation Festival was organized at the airport. I wrote "over" because most of the planes took off from Okęcie Airport. Only a few Po-2s and American Piper-Cups acquired from surplus took off from Mokotów. These were the last air shows in this place.

In 1948, Mokotów Airport disappeared from the aviation map.

Written by Karol Placha Hetman