Kraków 2020-10-31

The history of the General Electric J79 engine.

Movable aerodynamic blades of the compressor stator was one of the ways to improve the operation of the turbojet engine. General Electric has been considering for almost a year – Which concept to choose? In 1952, it was decided to use movable steering wheels. With this arrangement, it was easier to develop lubrication and sealing systems, which was not easy with a two-shaft arrangement. Competitor Pratt and Whitney chose a twin shaft system for the J57 engine. The system with movable steering wheels is used in the General Electric J79 engine. The factory designation of the X-24A engine. The compressor of this engine is as high as 17 degrees. The first few stages of the steering wheel on the compressor are adjustable. Their variable position regulates the speed of air flow and the direction of its swirls, improving the pressure distribution and preventing too much air from being delivered to the next steps. The engine is single-shaft, yet it has similar compression parameters as the first two-shaft engines of today, and with a significantly lower weight of the structure. The first tests were so good that the engineers suspected errors in the operation of the measuring equipment. The first air tests were carried out on May 20, 1955, on the B-45 C airplane. The engine was ejected from the bomb bay. After it was started, the standard engines were turned off and the plane flew with only one engine.

The engine was perfect for high-speed airplanes: F-104, B-58, F11F, F-4, A-5 and others. The commercial version marked CJ805 powered the Convair CV-880 and Convair CV-990 airliners. The CJ805 engine has no afterburner, but is equipped with a thrust reverser and silencer. Licenses for the J79 engine have been sold to several companies around the world (Belgium, Canada, Israel, Italy, Japan). In 1959, the J79 engine as a General Electric LM 1500 became the base for ship propulsion and as a stationary base for industrial applications. Over 17,000 J79 engines have been built for over 30 years.

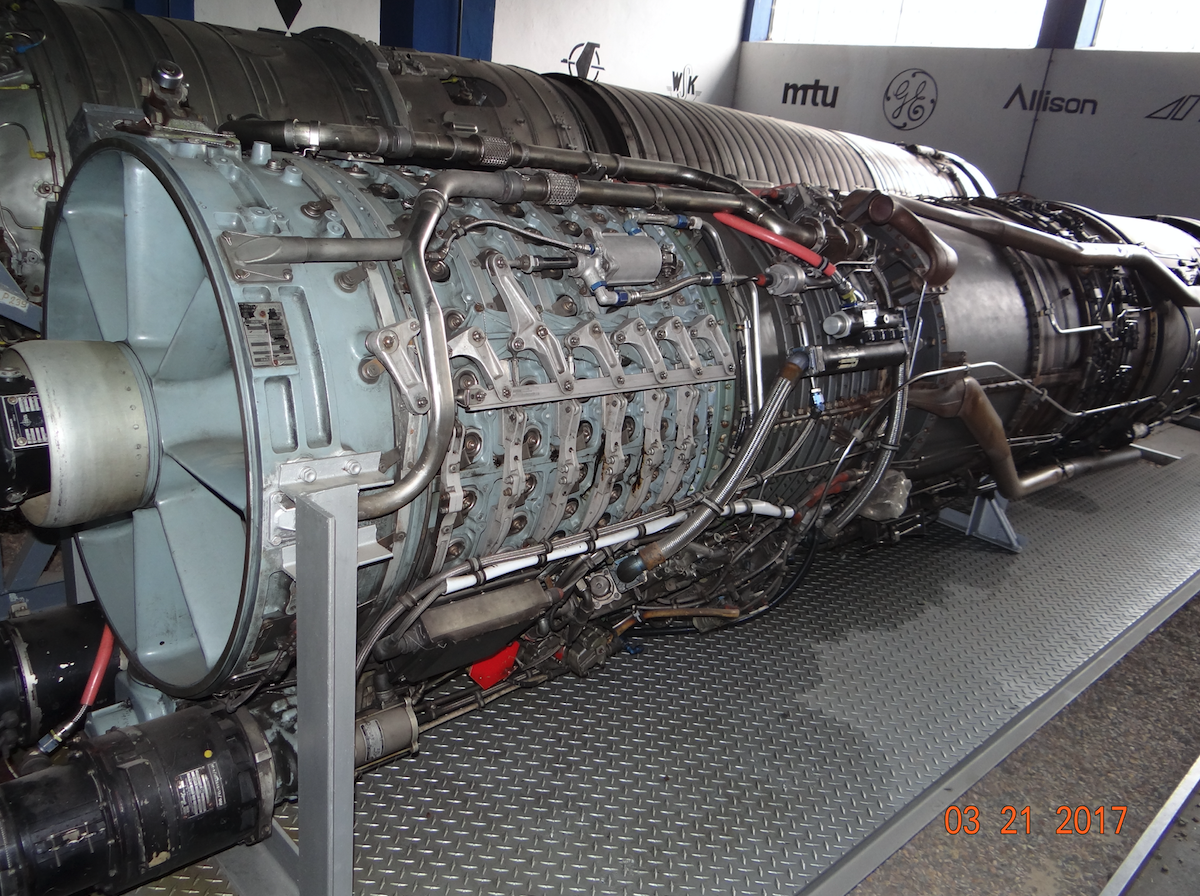

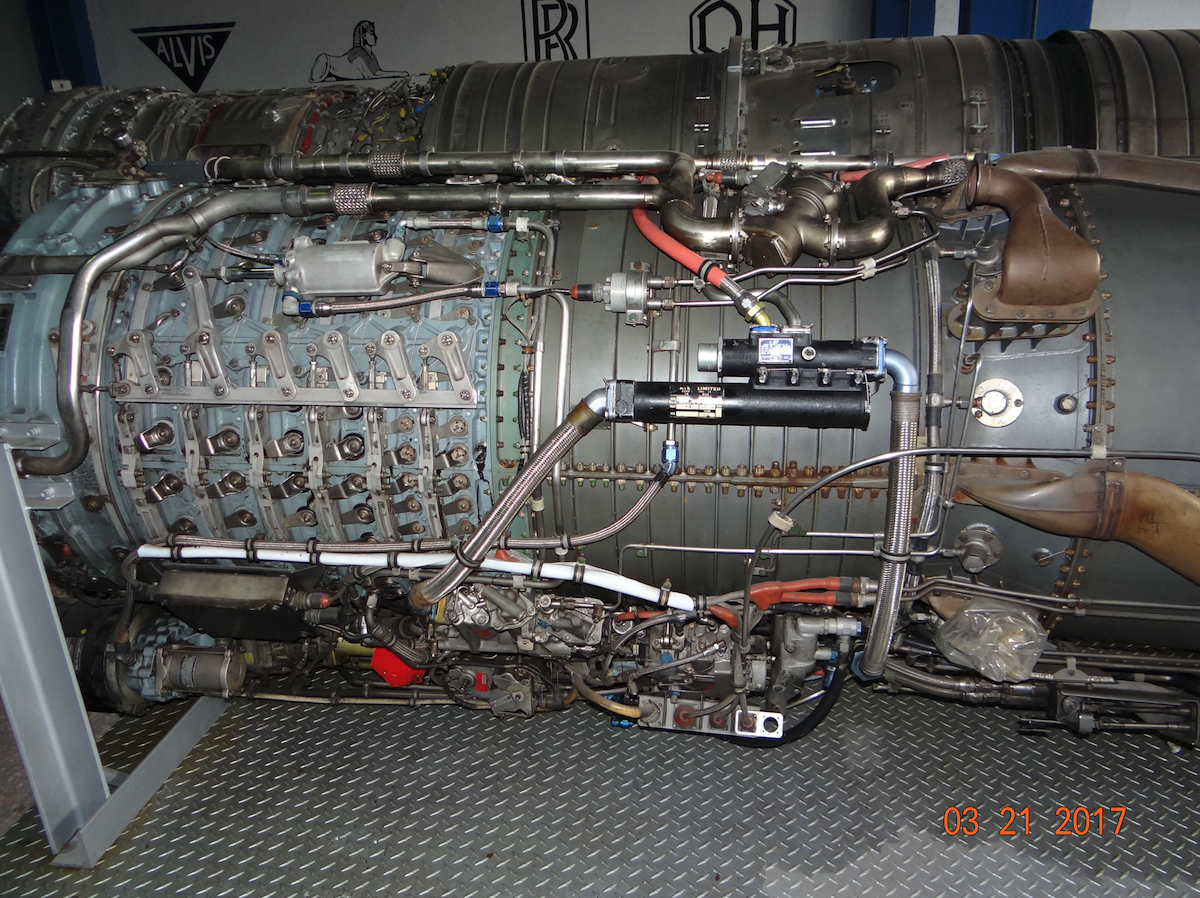

General J79 engine structure: 17-stage compressor, annular combustion chamber, 3-stage turbine. 5.30 m (17.4 ft) long, 0.98 m (3.2 ft) diameter, weight 1,750 kg. The compressor blades are made of stainless steel. They are embedded in disks. The first seven disks are made of titanium. They are inserted with steel discs made of stainless steel. Compressor compression is 13.5: 1. 77 kg / s of air flows through the engine. The temperature in front of the turbine is 930 degrees C. Fuel consumption 87 kg / kNxh without afterburning and 200 kg / kNh with afterburning. The thrust-to-weight ratio is 45.4 N / kg. 52.96 kN thrust without afterburning, 79.33 kN thrust with afterburning. Initially, the J79 engines were very smoky, especially at medium revs. This smoking was later limited.

In the UK, Rolls-Royce initially chose a solution with movable vanes between the compressor stages. However, the Rolls Royce Avon engine failed to achieve the results achieved by General Electric with the J79 engine. So it was decided to use only movable blades before the first stage of the compressor. The remaining vanes were replaced with an air bleed in the middle of the compressor’s length. The Rolls-Royce Avon engine was used in newer models of Comet commercial airliners and the French Caravell.

The J79 engine was originally known as the X-24A. The first launch of the General Electric J79 engine on the dynamometer took place in 1952. The XJ79-GE-1 prototype was first launched on June 8, 1954, and on the plane on May 20, 1955. The afterburning engine had a thrust of 63.83 kN. On December 8, 1955, a 50-hour test was performed. The first aircraft to be powered by a J79 engine was the Douglas F4D Skyray on-board fighter. Lockheed F-104 Starfighter, Grumman F11F Tiger, and McDonnell Douglas F-4 Phantom II were the next planes. The J79-GE-11A engine, used in the F-104G and TF-104G aircraft, has a thrust of 69 kN with afterburning.

In 1960, the price of the engine was $ 624,727. The General Electric J79 is a turbojet engine that can be used in supersonic airplanes up to the speed of the Ma-2. It was manufactured in the USA and under license in several other countries: Germany, Italy, Belgium, Canada and Japan.

Construction of the General Electric J79 engine.

The J79 engine is a single flow, single shaft engine with an afterburner. The engine starts with a cone with a turbo starter. There are eight fixed blades in the inlet, which organize the air flow.

The compressor is axial, 17 stages. The aerodynamic blades (stator) are placed between the compressor stages. The first seven stages of the stator (stator) are mobile. This was an innovative solution that allowed the engine to achieve an overall pressure ratio similar to a twin shaft engine at a lower weight. Compressor compression is 13.5: 1. The compressor blades are made of stainless steel and are mounted on discs. The first seven stages are made of titanium with spacers of corrosion-resistant steel. The remaining discs are made of steel. The engine has vents in front of the combustion chamber. Four of them are used to cool the afterburner tube. Three vents are used to compensate for too high air pressure in the system. The combustion chamber is tubular with a cooling system. The turbine has three stages. The afterburner increases engine thrust by 49.8%. The engine exhaust nozzle is adjustable.

Basic data of the J79-GE-11A engine:

Length 5.30 m. Diameter 0.98 m. Engine weight 1,750 kg. The maximum thrust without afterburning is 52.96 kN. The maximum thrust with afterburning is 79.33 kN. Compressor compression is 13.5: 1. The air flow is 77 kg / s. The maximum exhaust temperature before the turbine is 930 degrees Celsius. Fuel consumption without afterburning is 24.0 g / kNxs, and with afterburning – 55.7 g / kNxs. The thrust-to-weight ratio is 4.6: 1.

Written by Karol Placha Hetman