Kraków 2022-12-09

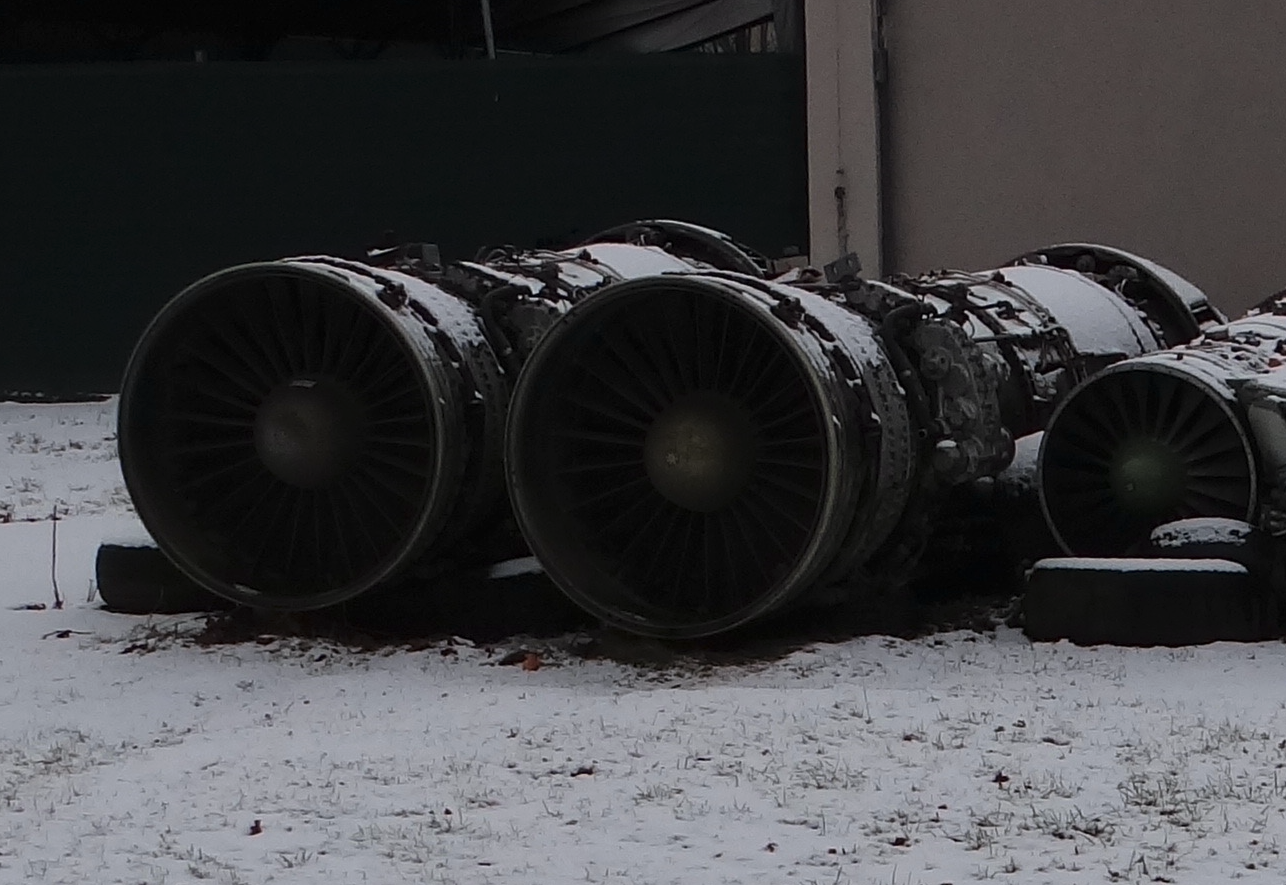

Soloviev D-30 twin-shaft, twin-pass turbojet engine.

There have been several significant inventions in the development of turbojet engines. One was a two-shaft system and the other was a two-flow system.

The Bristol Olimpus engine was the world’s first twin-shaft engine. Initially designated Bristol BE.10 Olimpus, it was developed by Bristol for V-class aircraft. It was to have a thrust of 10,000 lbf (44.48 kN). The first air tests were carried out in 1950 on the Avro Vulcan aircraft. Its development versions were used to power the BAC TRS-2 strike aircraft, and later as the Rolls-Royce – Snecma Olimpus 593 commercial Concorde.

The first two-pass engines were developed in parallel in several companies in the USA and UK in the mid-50s of the twentieth century. These engines gave rise to turbo-fan engines, which are characterized by high thrust.

In the Moscow state, the first single-pass, twin-shaft engine was the R-11, which was used to power the Mikoyan and Guriewicz MiG-21 fighter aircraft. But single-flow engines were not very suitable for propulsion of passenger aircraft due to their high fuel consumption. However, they had the advantage that with a small frontal area they were well suited for high-speed combat aircraft.

Work on a two-shaft and two-pass engine was started at the CCCP at the beginning of the 1960s. The task was undertaken in a team led by engineer Paweł Aleksandrowicz Sołowiew.

Paweł Aleksandrowicz Sołowiew (Па́вел Алекса́ндрович Соловьёв 1917-1996) was one of the constructors of aircraft engines in the CCCP. For many years he headed the OKB-19 office in Perm. He was born in the village of Aleksino, Ivanovo region. In 1934, he graduated from a 9-grade school and enrolled in the Aviation Institute in Rybinsk. After graduating in April 1940, he joined the team at OKB-19 in Perm (now the Aircraft Engines Bureau). Thanks to belonging to the communist party, he quickly moved up the career ladder. In 1948, he was the deputy head of projects. In 1953, he became chief designer at OKB-19 in Perm. In 1981, he became chief designer of aircraft engines at CCCP.

D-20 engine.

Under the direction of Paweł Sołowiew, work on a new single-flow engine began in 1955. The task was to develop an engine for the M-4 bomber, which was not implemented. In 1960, the D-20 engine was developed, which was decided to be used in the Tu-124 aircraft (a reduced version of the passenger Tu-104). It was the first two-flow engine in the CCCP. 700 (795) D-20 engines were built. The engine was in operation from 1962 to 1979.

D-20 engine T-T data:

The D-20 engine has a mass of 1,468 kg, a length of 3.304 m, a diameter of 0.915 m. It has a thrust of 5,500 kG. The thrust at 11,000 m at cruising speed is 1,150 kG. 3-stage low-pressure compressor (first stage works as a dual-flow fan), 8-stage high-pressure compressor, combustion chamber with 12 flame cans, 1-stage high-pressure turbine, 2-stage low-pressure turbine. The degree of two-flow is 1:1. The temperature in front of the turbine is max 1,057 degrees C. The total compression of the compressor is 14:1. Air flow 113 kg/s. specific fuel consumption is 0.88 kg/kG h at take-off and 0.72 kg/kG h during cruise. The compressor blades are attached to the disc in a dovetail fashion.

D-30 II engine.

On July 29, 1963, the first flight was made by the Tu-134 prototype, powered by Soloviev D-20 engines, with a thrust of 2 x 52.9 kN (2 x 5,394.30 kG). Already at that time, an improved engine was being worked on in Perm, which received the designation D-30. Work on the Soloviev D-30 engine began in 1963. The goal was to build a new engine for the Tu-134 aircraft. The starting point was the D-20 engine. In 1967, the engine was ready. Serial production started at the Perm plant, and from 1972 in Rybinsk. In 1970, a second version was developed, and in 1982 a third version.

T-T data of D-30 engine:

Engine length with thrust reverser is 4.734 m. Engine length without thrust reverser is 3.984 m Diameter 1.05 m. Dry engine weight 1,765 kg. Engine thrust is 68.00 kN (6,934 kG). The thrust at the cruising altitude of 11,000 m at Ma-0.8 is 14.22 kN (1,450 kG). The temperature in front of the turbine is 1,316 degrees C. Fuel consumption 0.77-0.79 kg/kGh.

The TRDD Soloviev D-30 engine is a two-pass, two-shaft engine. The 3-stage low pressure compressor works in cold and hot circuit as a fan. 8-stage high-pressure compressor, combustion chamber, 1-stage high-pressure turbine, 2-stage low-pressure turbine. It may have a thrust reverser fitted. It is activated automatically by compressed air. Since the engine is produced until now (2016), it has been equipped with an electronic control system. Two spark plugs are used to initiate the ignition. Automatic oil system. The oil works in a closed system. The engine runs on kerosene types: T-1, TC-1, PT.

Polish Tu-134 aircraft were equipped with: two Sołowiev D-30 turbo-fan engines in the Tu-134 version, with 2 x 64.5 kN thrust or two Sołowiev D-30 II turbo-fan engines in the Tu-134 A version , with a thrust of 2 x 66.7 kN, equipped with thrust reversers. One engine on a cruise flight burns an average of 1,178 liters per hour, or 19.64 liters per minute. To fly a distance of 100 km, one engine needs an average of 196 liters of aviation kerosene. These are average data, but they also take into account the take-off and landing of the machine. The aircraft was refueled from a tanker truck that was approaching the right wing.

The engines are started by an external starting unit placed on the chassis of the ZIL truck. The car was backing up to the left engine. It is also possible to start the D-30 II engine without airport power sources using an additional APU turbogenerator located in the tail of the fuselage with compressed air. This turbo generator is also used for ventilation, heating and air conditioning of the cabin. Generates electricity when the main engines are not running. Such a device enables the operation of the aircraft at airports without technical facilities. PLL LOT aircraft underwent inspections and repairs in Minsk.

D-30KU engine.

In the 1960s, the D-30 KU (Д-30КУ) and D-30 KP (Д-30КП) versions with higher thrust were developed, designed to power the Tu-154 M, Il-62 M, and Il-74 aircraft. About 8,000 were built. The engine was not only enlarged but also developed. 4-stage low-pressure compressor, 11-stage high-pressure compressor, combustion chamber, 1-stage high-pressure turbine, 2-stage low-pressure turbine. At the fifth and sixth stage of the high-pressure compressor, there is an air vent, which serves as anti-pump protection. The system operates automatically above 79% engine speed. The same inlets are used to start the engine with compressed air from the airport generator or a second engine. After separating the air into the cold and hot duct, and before the first stage of the high-pressure compressor, adjustable aerodynamic vanes were placed. They are automatically controlled and coupled with the anti-pumping system. These engines were the first engines in the CCCP that had a significantly higher cold flow compared to hot (2.54:1).

T-T data of the D-30 KU engine:

Diameter 1.46 m. Length 4.83 m. Curb weight 2,305 – 2,320 kg. Gross weight 2,668-2,675 kg. Air Compression 17:1. The gas temperature in front of the turbine is 1,660 degrees Celsius. Fan diameter 1,455 m. Air flow 264-269 kg/s. 105.72 kN (10,780 kG) thrust. The thrust at the Ma-0.8 cruising speed and the ceiling of 11,000 m is 28.10 kN (2,865 kG). Fuel consumption 0.69-0.71 kg/kGh. The motor’s two-flow ratio is 2.54:1.

Polish Il-62 M passenger planes were powered by engines from the Sołowiev D-30 KU office with a thrust of 4 x 107.9 kN (4 x 11,500 kG).

Numerous versions of the D-30 engine resulted from its good characteristics, especially against the backdrop of the Kuznetsov NK-8 engine. More thrust, less fuel consumption, less failure rate and no better proposition. A non-aviation version of the engine has also been developed for industrial applications.

Let’s remember, however, that the D-30 KU engines were sloppy. During production and repairs, numerous inappropriate modifications were made, which caused failures, and these led to disasters. For example, bearings were changed to ones with fewer rollers. Due to surface corrosion, the shaft was re-machined (rolled), making it thinner and weaker.

On the basis of the D-30 engine, the D-30F6 (Д-30Ф6) engine with an afterburner and without a thrust reverser was developed for the MiG-31 combat aircraft, but it has little in common with the D-30 engine.

Speaking of the D-30 engine, we will mention the deep modernization of the engine at the end of the 90s. A version designated D-30KP-3 "Burlak" (Д-30КП-3 "Бурлак") was developed at Saturn. The main change was the introduction of a new fan. Engine thrust increased by another 9.81 kN (1,000 kG). Fuel consumption decreased by 11%. Noise and exhaust emissions have been reduced.

The last aircraft to be equipped with D-30 engines was the Be-42 flying boat.

Written by Karol Placha Hetman