Kraków 2016-05-10

Internal combustion-piston rotary engine.

This article is the second in a series discussing aircraft engines. In this article, we will introduce rotary motors.

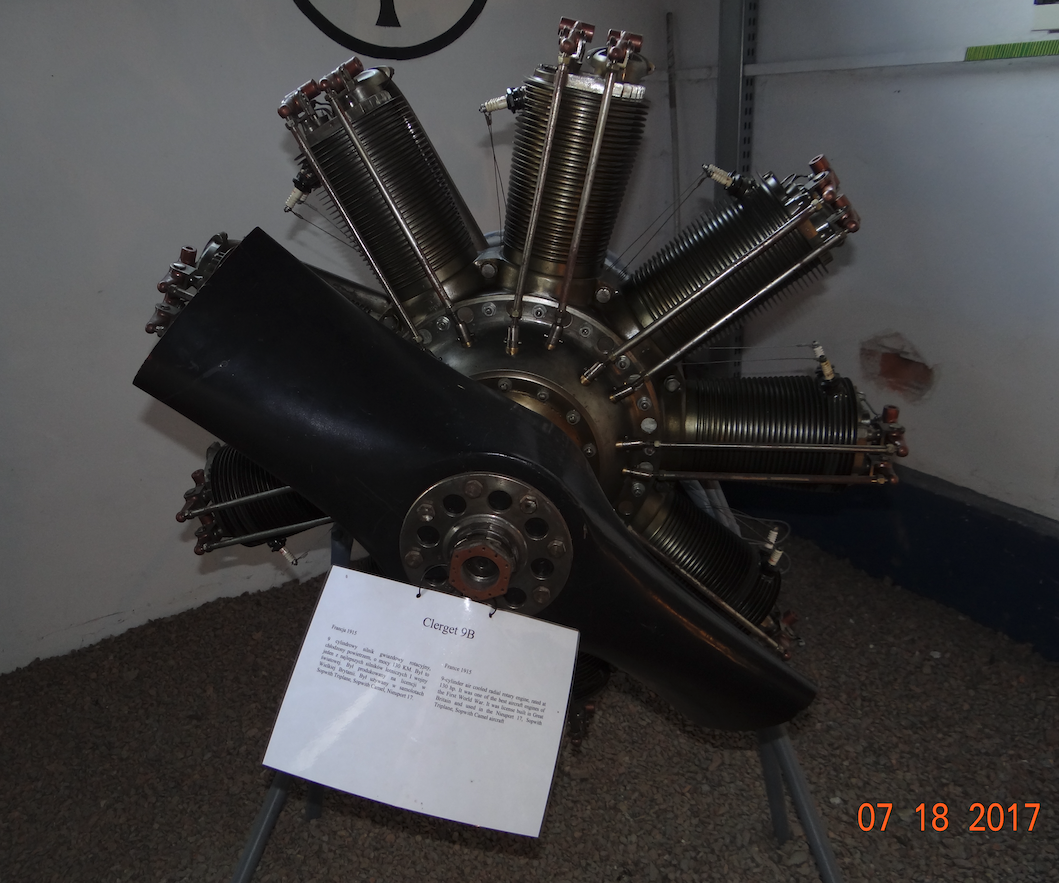

Description for the photo: 9-cylinder, radial, rotary, air-cooled engine, 130 HP. Built in France in 1915. The engine was manufactured under license in the UK and the USA. The engine was mounted on the following airplanes: Sopwith Triplane, Sopwith Camel, Nieuport 17.

Description for the photo: 9-cylinder, radial, rotary, air-cooled, 80 HP engine. Built in France in 1913. The engine was installed on the following aircraft: Nieuport 16, Hanriot HD-14, Morane-Saulnier MS-30, Morane-Saulnier MS-35.

Rotary radial motors should not be confused with motors with a rotating piston, as is the case with a Wankel engine. Rotary star engines are already historic designs and no new designs are being developed. However, in the period 1913-1920, these types of engines were very popular and widely used. They were built in thousands and powered thousands of airplanes, as well as, for example, motorcycles.

The idea behind the rotary engine operation is as follows; the crankshaft is stationary and is part of the engine’s attachment to the aircraft structure. The rotary movement is performed by the cylinders with the body together with the pistons. The propeller blades are attached to the body. This is a reversal of the rule in the now classic stellar engine. They were usually built as a single star. Much less often double. The fuel-air mixture in rotary engines is supplied by the crankshaft. The intake was realized through slots in the cylinder in a two-stroke engine or through valves in the head of a four-stroke engine. On the other hand, the exhaust was always through the valve in the head opened with a pusher.

The cylinders usually had no or small cooling fins. Due to the rotational movement of the entire body, the cooling of such an engine was very efficient. Good cooling favored the use of higher compression ratios. These engines were lightweight and well-balanced. They were willingly used to propel small and light aircraft. They were used to power cars and motorcycles, which they found their way to at the end of the 19th century. The aircraft rotary engine was first widely used by the French brothers Laurent and Louis Séguin, who began producing these engines under the name Gnôme. Rotary engines were widely used at the beginning of aviation and during the Great World War to propel light aircraft, including many of the contemporary fighters; Nieuport 11, Fokker E.III, Sopwith, and in Poland by the Wielkopolska Wytwórnia Samolotów “Samolot” to propel Bartel BM-4a and Hanriot HD planes.14. Such engines were also used to propel smaller airships, where they performed very well. Rotary engines had the power of 50-200 HP.

If these engines were so good, why were they only built until the end of the Great World War? First, the engine was lubricated in an open circuit, i.e. used oil was thrown out of the cylinders. They also consumed a lot of fuel. Designers encountered huge problems with the construction of rotary motors with higher powers. Besides, the rotary engine was not liked by the pilots. Especially beginners. The large rotating mass of the engine created a gyroscopic effect. The plane made left and right turns at different angular speeds. In one side (usually to the right) he would more readily enter and make a tighter turn. Experienced pilots were able to use this in air combat. Double star engines, on the other hand, tended to overheat the cylinders of the second star because they were operating in the heat emitted from the first star. The rotational speed of the rotary engine was limited, which effectively limited the effort of the engine in order to obtain the greatest possible power from the capacity unit. There were also cases of the entire engine breaking off during operation. It happened when the engine or its mount failed. Very quickly the powerplant lost its balance, oscillated strongly and fell off the airframe. The rescue was a quick engine shutdown and landing.

Clerget.

The French constructor Pierre Clerget (1875-1943) is commonly considered the creator of the rotary engine. Pierre Clerget was an engineer, inventor, and industrialist. An aviation pioneer who devoted his life to an aviation engine. He designed one of the first diesel engines for aircraft. At the age of 14, in 1889, he and his father visited the Paris Universal Exhibition, where he had the opportunity to speak with the then recognized Gottlieb Daimler and Armand Peugeot. This made the boy fall in love with internal combustion engines and began to design and build them. In 1895 he became an engineer. From 1905, its engines were mass-produced by the French company Clement-Bayard under the name Clerget. From 1911, the Clerget 4-cylinder 100 HP engine was produced, used to propel airships and airplanes, including water-planes. This engine was developed into an 8-cylinder design and developed 200 HP. It had a sensational power-to-weight ratio back then. On August 18, 1913, Pierre Clerget with his partner Eugene Blin founded the Clerget company in Levallois-Perret, whose main production was aero rotary engines. Pierre Clerget assumed that the plane needed an engine that was small but powerful, and the rotary engine met these requirements. Production of two basic models commenced: the 7-cylinder 60 HP and the 9-cylinder Clerget 9A with 110 HP and a capacity of 15 liters. The first consumed 42 liters of fuel per hour and 5.70 liters of oil per hour. They were then more competitive than Gnome rotary motors. Clerget engines have been used to power aircraft such as the Sopwith Triplan. In 1914 a variant of the Clerget 9B 130 HP engine with a capacity of 16 liters was created. Most of the production was exported to the UK. The engines were so popular and sought after that other UK factories were involved in their production: Gordon Watney, Gwynnes Ruston, Proctor and Humber-Bentley (Bentley Br.1 and Bentley Br.2 engines with a maximum power of 234 HP). The engines went to such machines as: Sopwith 1½ Strutter, Sopwith Baby, F1 Camel, Nieuport 12, Avro 504 and others. The end of the Great World War caused an avalanche drop in orders for aircraft engines. As a result, several aviation companies went bankrupt, including the Clerget factory in Levallois-Perret. Pierre Clerget himself began designing aero diesel engines. In 1929, the Disela Stae Clerget 9A engine weighing 228 kg and 110 HP was created. It must be remembered that the Desla engine was perfect for sea planes, because due to the high humidity of the environment, it was less sensitive to failures, because it did not have spark plugs. In 1932, a 14-cylinder Disel with 300 HP was created, and in 1934 a 14-cylinder with 400 HP. After the development of double direct injection, power increased to 450 hp. The engines were built by Hispano-Suiza and tested by Potez. In 1938, Pierre Clerget’s Disel engines developed 520 HP. In 1943, the constructor was found dead in one of the Paris canals. Perhaps he committed suicide. The circumstances remained unclear.

Coming back to the rotary engine of the Clerget system, the most powerful of them reached the power of 150 HP, with a 9-cylinder system. As it was manufactured by other factories outside of the license, it received different names. This production was carried out mainly in the UK and the USA. In the UK, the Clerget system engines were installed in such a popular aircraft as the Avro 504. The aircraft was first flew in 1913 and about 9,000 machines were built, equipped with various rotary engines, including the Clerget system.

Gnome.

The second rotary engine was the Gnome engine, with 80 hp and its variants. Gnome was the first to launch large-scale production of rotary engines for aviation in 1913. These engines were designated Gnome Monosouppap, which meant Single Valve. They were also marked Gnome 9, which meant 9-cylinder. Subsequent versions ranged from 80 HP to 170 HP. These engines had a single valve in the cylinder (exhaust valve) as they operated in a two-stroke system. In such an engine, each cylinder that is in the upper position gets ignition. So all strokes (intake, compression, exhaust) were realized within one revolution. In a four-stroke engine, every second cylinder in the upper position received ignition. So the entire cycle in one cylinder was carried out during two revolutions of the entire engine.

Gnome rotary engines were used, among others, in the Thomas-Mores S-4 Tommy aircraft. The aircraft was developed in 1916 during the Great World War in the USA and built in over 600 units. The Gnome engine used to propel the plane was considered questionable. Opinions about him ranged from delightful to definitely negative. The engine in flight consumed approximately 11 liters of castor oil per hour and 45 liters of fuel per hour. Burnt oil, ejected by the cylinders, covered the lower right lobe and the right side of the fuselage. The fuel system, in the event of a failure, could spray fuel onto hot cylinders and lead to a fire. On the other hand, the plane was leaving the ground very quickly and had a high rate of climb, reaching a high altitude. About 300 Thomas-Mores S-4 Tommy aircraft with the Gnome engine were built.

Le Rhône.

The Gnome engine was replaced with the Le Rhône C-9 80-110hp engine, which was built under license by the United Switch and Signal Company factory. This engine consumed only 4 liters of oil per hour. Of course, this aircraft with a rotary engine had typical problems of this type of propulsion. The aircraft was very maneuverable and was well suited for the role of an advanced training aircraft and as a light fighter. Still, some acrobatic figures were difficult or even impossible to make. All through the gyroscopic effect. The engine and propeller turned clockwise. During the quick take-off, right after taking the plane off the ground, it was necessary to immediately counter the roll to the right wing. It was not recommended to make a deliberate clockwise spin below 1,200 m (4,000 ft). The plane made a right turn almost on the spot. It was facilitated by a heavy tail that was easily thrown sideways. Therefore, the control surfaces had angle limiters. However, experienced pilots dismantled these limiters and made tight turns inaccessible to other aircraft. The gyroscopic effect of the engine meant that the turn left was incomparably longer than the turn right. Likewise, the barrel to the right was much faster than the barrel to the left. The correct execution of the loop required simultaneous large deflection of the rudder to the left. For an experienced pilot, these disadvantages turned into advantages and they were eagerly flown on them. The plane was definitely described as aerobatic. It had a relatively large drive wheel (rotating propeller) and a short undercarriage. As a result, the distance between the propeller and the ground during take-off was small, so for an inexperienced pilot, the touchdown could end in an accident.

In later years, many aircraft received classic radial engines. This caused the plane to slightly change its flight characteristics. However, the heavy tail still favored the tight turns. In civilian law, airplanes were used as racing machines. A large number of machines built and their low price on the secondary market resulted in the enormous popularity of the structure. These planes took part in many historical films, imitating other designs of the Great World War.

This is how we introduced the third and most famous Le Rhône rotary engine. It was by far the best and longest used in the world. Even in the 30-year period they were made popular. They had power from 80 HP to 110 HP. Le Rhône C rotary engines, 59 kW (80 HP), were also used on Nieuport fighter planes, of which approximately 7,200 were built during the Great World War. The rotary engine went to the Nieuport 11 Bebe version in 1915. This plane allowed the Allied forces to regain advantage over the Central Powers and the flagship Fokker E-I fighter. Nieuport 11 Bebe aircraft were built in France, the Netherlands, Italy and Russia. It was realized that the power of 80 HP was a bit too low. However, all attempts to mount more powerful engines were unsuccessful. The engines either had a worse power-to-weight ratio or were defective. The Nieuport 11 C-1 planes were also used by Poles in the aviation service of Tsarist Russia.

In the literature on the subject, we can find other rotary engines. One of them is Oberursel Ur. II (UR II). It is a licensed variant of the Gnome engine built under license in Germany.

The rotary engine came to Poland along with the French Hanriot HD-14 training plane. In 1923, using a loan granted to Poland by France, 50 machines and a license for their production were purchased. In fact, 70 aircraft were delivered to Poland, the deliveries of which began in 1923. In total, Poland had 295 Hanriot HD-14 aircraft in various variants. For license production in November 1923, a model copy was delivered to the Central Aviation Workshop. Preparations for serial production were carried out from September 1923. However, the documentation received was inaccurate as it referred to the earlier Hanriot seaplane in some elements. In fact, the documentation was re-created, which extended the work. It also includes modifications made to the Hanriot HD-28 aircraft. The Hanriot HD-28 aircraft was a metal structure compared to the Hanriot HD-14, which had a wooden structure. As a result, the Polish Hanriot H-28 was intermediate between the French HD-14 and HD-28. 125 machines were built. Then the production was started by Wielkopolska Wytwórnia Samolotów "Samolot" in Poznań, and the first flight was made on February 20, 1925. 120 machines were built. These planes served in the Polish Army until 1935, and then in the civil aviation until 1937. About 130 HD-14 and H-28 machines were operated in civilian life. All aircraft were powered by Le Rhône C engines with a nominal power of 59 kW (80 HP). Airplanes had the typical ailments of airplanes with rotary engines. The plane took off from the ground already at a speed of 65 km / h and reached 115 km / h. The plane had a long flight time. About 3 hours, which allowed for long training without frequent refueling.

In 1926, at the Central Aviation Workshop in Warsaw, Capt. Aleksander Sipowicz built an experimental aircraft designated Sipowicz-1 (Kapitan Sipowicz-1). The constructor used the plane of his idea on it, with a negative lift and with an additional oblique plane on the rear brace in order to provide the plane with better lateral stability than in other machines. The tail came from the Ansaldo A-1 Balilla and the fuselage was taken from the Nieuport 80 E2, complete with the 59 kW (80 HP) Le Rhône C rotary engine. The aircraft was flown by the designer in 1926 and showed good piloting properties. The machine remained in one copy, which was modified several times.

In 1927, at the "Samolot" Airplane Works of Wielkopolska, Eng. Ryszard Bartel developed the Bartel BM-4 aircraft. Due to the large supply of Le Rhône C 80 HP engines, it was used in the BM-4a variant. In this design, the engine achieved its nominal power at only 1,200 rpm, which allowed the use of a propeller with a diameter of as much as 2.55 m. This allowed for quite good performance of the plane. Take off from the ground already at 60 km / h. Max speed 125 km / h. Range 315 km. Flight time 3 hours. However, due to the disadvantages of the rotary engine, another six variants of the Bartel BM-4 aircraft with different engines were created.

The bi-rotary motor of engineer Henryk Brzeski.

Attempts were made to create a turbulence engine in which the shaft with the propeller rotated in one direction and the engine body in the opposite direction. However, there were problems with mounting such a power unit. In addition, in such an engine the problem of cylinder overheating returned.

As early as 1907, biirotation engines were constructed by Poles, thanks to the Polish engineer Henryk Brzeski. Henryk Brzeski was a talented inventor and designer. He worked as an assistant to professor Kohlrausch in Hannover. In 1910, the engineer Henryk Brzeski in Vienna built a bi-rotating engine called "Iskra" with a capacity of 70 HP (51.5 kW). It was the world’s first engine of this type and Henryk Brzeski obtained a patent for it. This engine powered two two-blade counter-rotating propellers. This power unit was installed in the plane of the brothers Wincenty and Rudolf Schindler called Aquila, which was built in Krakow in 1910. Apart from the innovative power unit, the plane did not have a vertical tail and a rudder. Unfortunately, the plane crashed shortly after take-off. According to available information, Henryk Brzeski sold his patent to Gnome and Siemens. Henryk Brzeski, an engineer, continued to develop new biirotation engines. In 1929, he developed a 137hp engine.

Written by Karol Placha Hetman