Kraków 2008-11-19

PZL WSK Mielec TS-11 Iskra.

171b Section 5 February 1960 year. Trainer and combat aircraft.

History

In the 1980s, pilots of turbojet-powered military aircraft found the romance of flying at the controls of light sports planes and gliders, because there was contact between the earth and the sky. Jet airplanes were often referred to harshly as "pipes" or "female dogs". The pilots referred to only one jet affectionately as Iskierka, and they meant the TS-11 Iskra training aircraft.

Creation of the TS-11 Iskra aircraft.

When the Polish Military Aviation was equipped with turbojet-powered aircraft in 1952, there was a need to develop a new training aircraft with this type of drive. An all-metal structure was required, with a retractable landing gear, a front wheel and characteristics similar to those of the MiG-15 and Lim-1 combat aircraft, widely used in the first half of the 1950s.

In 1956, the Air Force Command prepared tactical and technical requirements (WTT), which became the basis for developing the project of a Polish training jet. The development of the new structure was undertaken by the Aviation Structures Center at WSK PZL Warszawa Okęcie. The team was led by assistant professor of engineering (later professor) Tadeusz Sołtyk. This team already had several successful designs, including the TS-8 Bies aircraft, which was also used as a training aircraft. The requirements included a maximum speed of Ma-0.8, but at the same time the plane had to have good landing characteristics. Therefore, a straight but thin profile wing was chosen. The engine was placed in the central part of the fuselage. To prevent a reduction in engine efficiency, a short exhaust pipe was designed. Therefore, the hull became of the redan type. The disadvantage of this solution is excessive heating of the rear part of the aircraft. To prevent this, the designers moved the engine axis away from the beam and shaped the hull so that the cold air flowing around the hull separated the hot gases from the structure.

A significant problem to solve was the arrangement of pilots in the cockpit. When a student and instructor sit side by side, the instructor constantly sees the student’s behavior and activities. This solution, however, significantly increases the cross-section of the aircraft and thus the drag of the flying aircraft. To maintain similar flight parameters, a more powerful power unit must be used, which increases costs. When the instructor sits behind the student he has less control over the student, but not the airplane. Appropriate equipment solves the remaining problems. Additionally, attempts were made to keep the fuselage cross-section as small as possible to further reduce the aerodynamic drag of the aircraft.

The equipment used in the plane was to enable flights in all weather conditions, day and night, as well as without visibility of the ground.

TS-11 prototypes.

At the end of 1957, a mock-up of the plane was ready. It was made to check the appropriateness of the equipment deployment and to check the comfort of work of the crew and ground staff. The model was made of wood, on a scale of 1:1. The model was distinguished by a cannon built into an additional gondola suspended under the hull in its right part. The DWL (Air Forces Command) model commission in 1957-1958 assessed the model and preliminary design. The evaluation was positive, although the committee had some important observations and comments.

Further work was continued at the Aviation Structures Center at WSK Okęcie, where the team of engineer Tadeusz Sołtyk was transferred. In 1958, the WSK Okęcie plant started building four planes. In March 1959, the construction of the TS-11-01 static test airframe was completed. About 50 different trials and tests were carried out on the airframe. In December 1959, the first flight test prototype TS-11-02 was completed. It is equipped with a Viper 8 engine with a thrust of 1 x 7.80 kN (1 x 795 kG). The first flight was made by test pilot engineer Andrzej Abłamowicz on February 5, 1960. A few days later, an official demonstration of the plane took place on the ground and in the air for representatives of the party and military authorities. On September 11, 1960, the prototype was publicly demonstrated in flight over Łódź, on the occasion of Aviation Day.

The aircraft’s tests conducted in 1960 were divided into several phases. Initially, the aircraft’s performance was checked by comparing it with the adopted assumptions. Then, the flight characteristics and the ability to perform higher flying figures were checked. The first flights also included tests of the cabin canopy drop and the operation of the ejection seats. The seats were fired both with the canopy down and through it.

The TS-11-03 prototypes first flew in March 1961, and the TS-11-04 made their first flight in July 1961. What distinguished them from the first prototype was their drive. The planes were equipped with a Polish HO-10 engine with a thrust of 1 x 7.84 kN (1 x 800 kG) and the planes were armed with a 23 mm cannon. Detailed tests were carried out on these aircraft in terms of performance, stability, controllability and flight safety. Particular attention was paid to difficult configurations and failure states. The behavior of the aircraft during stalling and spin was examined. Self-excited flutter vibrations were investigated. It turned out that flutter does not occur within the intended operating speeds. Positive factory tests resulted in the aircraft being recommended for state tests.

State trials were conducted in mid-1961. It was found that the aircraft meets the assumed requirements and is a promising design. The plane is easy and correct to fly and move on the ground (taxiing). The plane is agile and stable in flight. Only the forces from the ailerons on the control sticks were too high, and the forces from the rudder were too small. The first problem was eliminated by installing hydraulic amplifiers. The second is by changing the control mechanism. The cabin is spacious and the visibility is good. The instruments in the cabin were arranged logically, systematically and purposefully, eliminating to a minimum the possibility of error by the student pilot. The aircraft’s automation was at a high level. One button starts the engine, one button extends and retracts the landing gear, one button activates the wing flaps. The tests ended with a positive evaluation. It was found that the structure fully meets the requirements. The preparation of documentation for series production has begun.

Presentation of the TS-11 Iskra aircraft in Moscow.

At the beginning of August 1961, pilots Józef Manet and Andrzej Abłamowicz flew on the TS-11-03 plane to Moscow. The flight took place in stages; Warsaw – Belarusian Minsk – Smolensk – Kubianka – Moscow. There, at the airport of the Aviation Academy in Monino, comparative tests were carried out with the Russian Yak-30 nb 90 and the Czechoslovak L-29 Delfin nb 0003. The tests were intended to select a training aircraft for the entire communist camp. These interesting trials lasted almost two months. The Russian Yak-30 plane fared the worst. The plane was the lightest of the three, and despite similar engine power, it was the slowest, both in horizontal speed and climb. The designers of the Yak-30 aircraft did not provide any armament for it. The Czechoslovak L-29 Delfin performed quite well. The best result was the TS-11 Iskra plane. However, the Kremlin decided that the standard training aircraft for Warsaw Pact countries would be the L-29. Moreover, CCCP recommended this aircraft to all potential allies outside Europe. Only in Poland it was decided to keep its Iskra aircraft.

In recognition of his services related to the development of the aircraft, doc. MSc. Tadeusz Sołtyk received the Award of the Minister of National Defense. In the "Życie Warszawy" newspaper competition for 1962, the entire construction team received the title of Master of Technology.

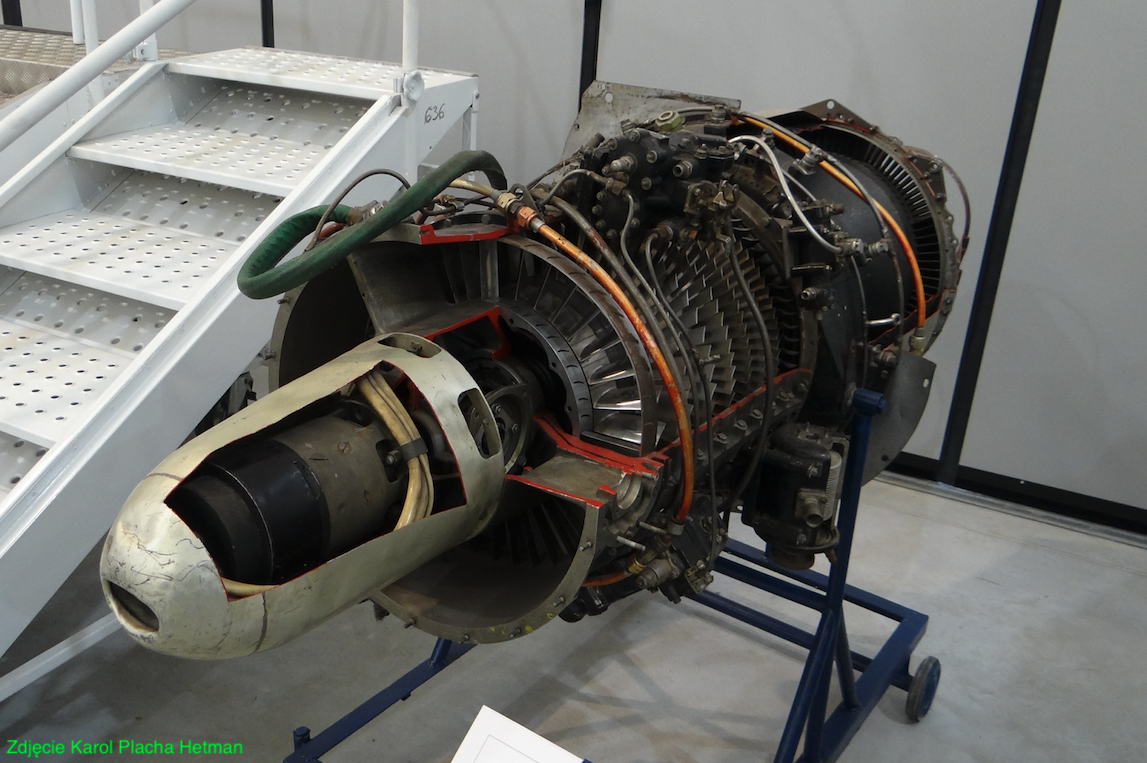

Viper 8 engine.

Because it turned out that the Polish engine, which was being worked on at the Institute of Aviation, would be suitable for installation in an airplane later than the airframes were built, it was decided to purchase the engine abroad. The choice fell on the British Viper 8 engine, commonly used in aviation, with a thrust of 1 x 7.80 kN (1 x 795 kG). The engine was bought in Yugoslavia, not entirely legally. In fact, this engine should never have been in the Polish People’s Republic, due to the fact that it was an engine from behind the "Iron Curtain". This engine was installed on the first flying prototype TS-11-02.

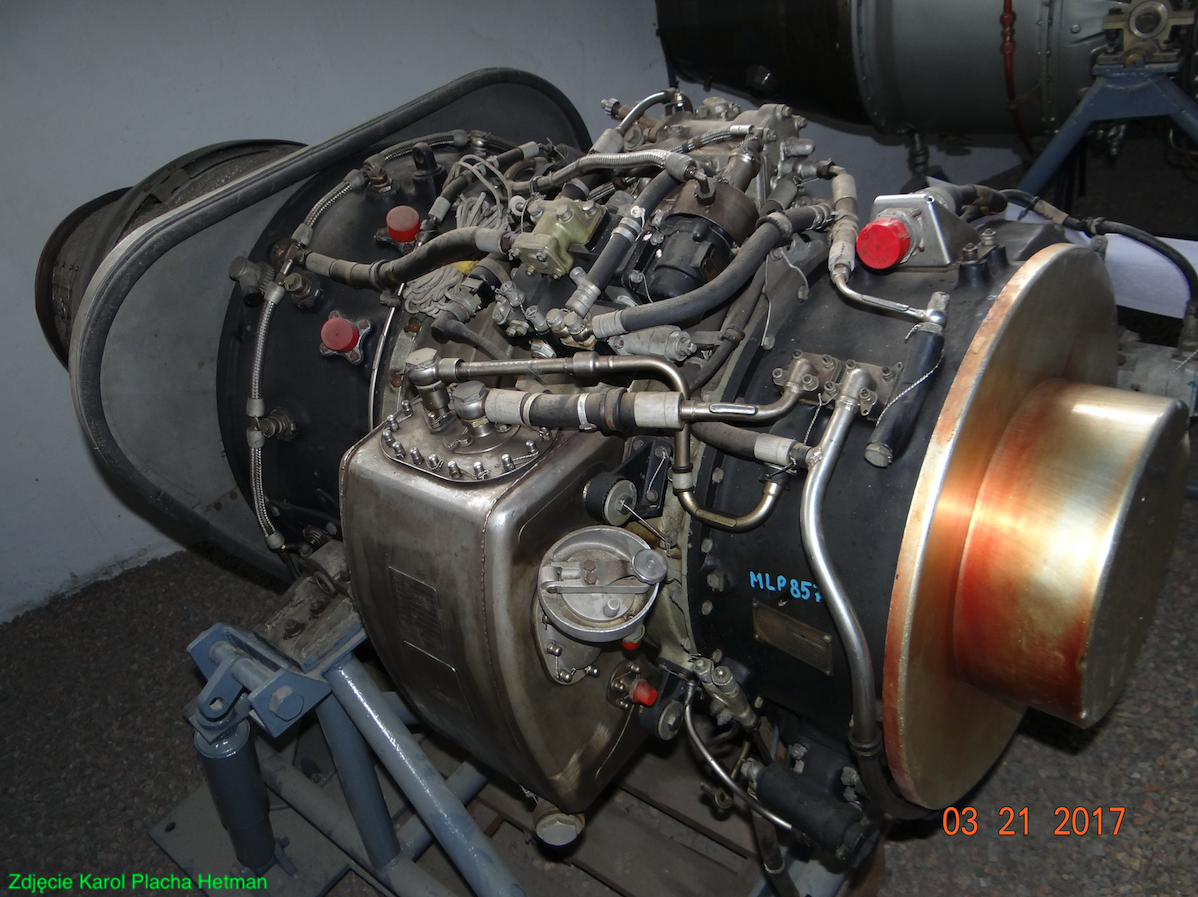

HO-10 engine.

The Viper 8 engine was copied at WSK Rzeszów and mass-produced under the name HO-10, with a thrust of 1 x 7.84 kN (1 x 800 kG). These engines were installed on the TS-11-03, TS-11-04 prototypes, and then on the first production series aircraft.

The development of the HO-10 engine began on February 1, 1958. The team that received this task had already developed the TO-350 experimental engine with a thrust of 1 x 3.4 kN (1 x 350 kG). The construction of the new engine used materials available in the country, which was related to the production of Lis family engines (license engine). The technological documentation of the engine was completed on October 30, 1958. The construction of the first copy was completed in December 1959 and research began immediately. By June 8, 1961, 7 copies of the HO-10 engine were manufactured. A total of 10 prototypes were built. This engine was mass produced in the period 1961-1964.

HO-10 is a classic single-flow turbojet engine. It consists of a 7-stage axial compressor, an annular combustion chamber with fuel evaporation, a 1-stage axial turbine, and an outlet pipe with a nozzle cap of constant cross-section. The engine has dimensions; length 2.253 m, maximum height 0.715 m, maximum width 0.767 m. Its service life between repairs is 200 hours. In 1961-1962, tests were carried out on the HO-10 engine equipped with an afterburner. The engine had the opportunity to increase the take-off thrust for 3 minutes to the value of 1 x 9.21 kN (1 x 940 kG), i.e. by approximately 20%.

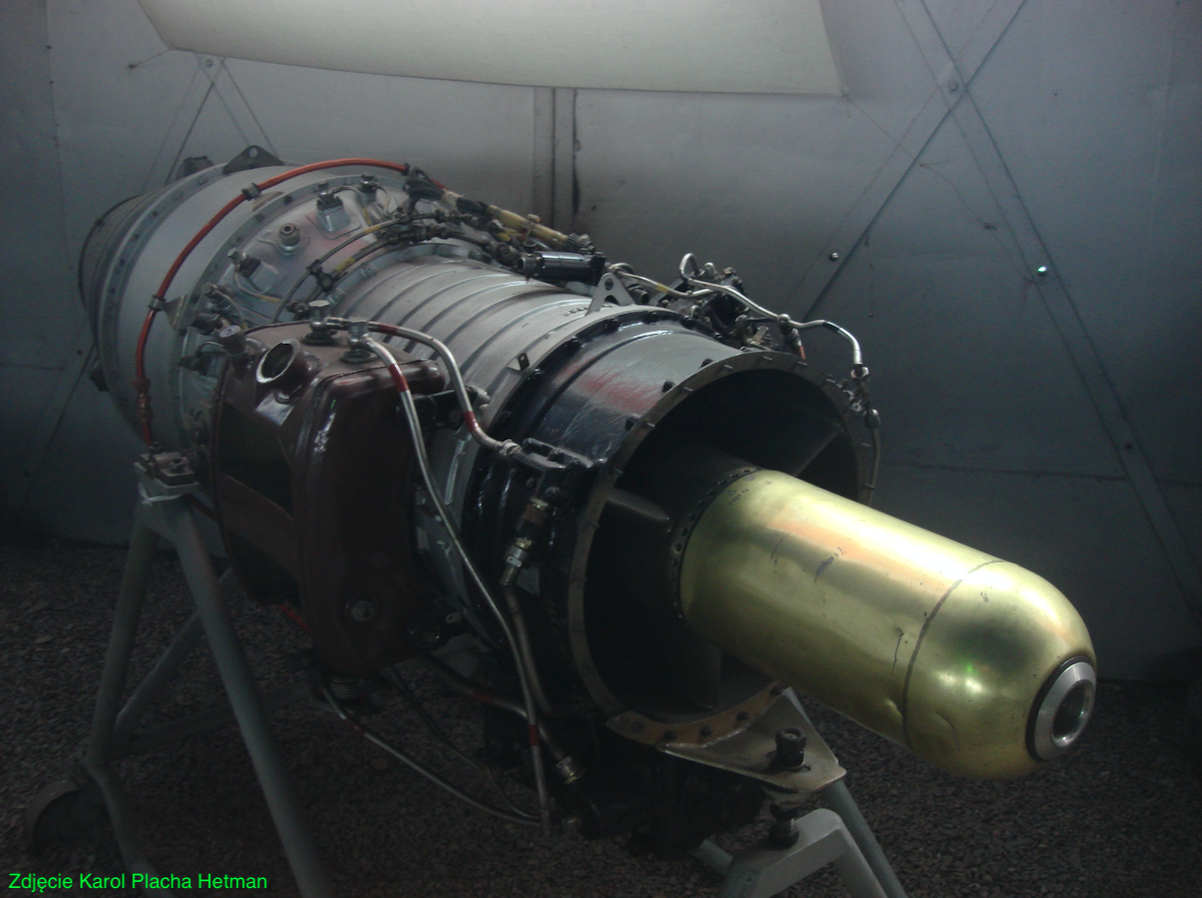

SO-1 engine.

The SO-1 engine was developed at the Institute of Aviation specifically to power the TS-11 aircraft. On April 28, 1964, the TS-11-03 aircraft took off for the first time with the new drive installed. It was installed on planes produced between 1967 and 1969. The purpose of the engine had a decisive influence on its layout and design. The conditions of use of the engine during training and training place particularly stringent demands on it. First of all, engines in this type of aircraft have a very large number of starts and changes in operating conditions. Meaning; thermal loads change frequently, there are frequent overloads related to aerobatics, frequent flights in an inverted position, and they must also have high resistance to incorrect control. Specific fuel consumption is not a strict criterion due to the fact that flights are mainly of short duration.

The analysis of the requirements and the resources available led to the construction of an engine with an axial-type compressor, an annular combustion chamber, and a 1-stage turbine. The pressure was selected high enough to avoid compressor mechanization and to use a single-stage turbine. The choice of an annular combustion chamber with fuel evaporation was dictated by the uniformity of temperature distribution within the turbine, as well as the durability and simplicity of such a structure. The temperature in front of the turbine was assumed to be 1,110 K to avoid the need to cool the blades. The lubrication system is designed to provide unlimited flight time in the inverted position (on the back). A 7-stage axial compressor with an air flow of 18 kG/s, consisting of a rotor and a body with a set of vanes. Annular combustion chamber with fuel evaporation. The glow tube is made of a nickel-chromium alloy. Likewise the cover. The chamber has 24 vaporizers, which are supplied with fuel by 12 dual jet work injectors, 6 starting injectors and 2 high energy spark plugs. The turbine assembly consists of a rotor, a set of vanes, a partition and a turbine cover. Single-stage reaction turbine. Four thermocouples are used to measure the temperature of the gases behind the turbine. In starting conditions, a maximum of 973 K. The outlet pipe has a constant cross-section, has an outer jacket and a cone with three radial flanges.

The engine lubrication system consists of two parallel circuits; The first one, circulating, lubricates the front bearing of the transmission and the drive of the units. It is powered directly by a two-section pressure and suction gear pump. The second – open circulation, with oil loss. Lubricates the middle and rear transmission bearings. Powered directly by micropumps. The design of the lubrication system guarantees correct engine operation at various flight speeds and altitudes, in normal and inverted flight. This is ensured by a reverse flight valve built into the drive box and a reverse flight regulator located in the oil tank.

The fuel system consists of a fuel pump, automatic control, acceleration automatic, max speed corrector, electromagnetic valves and cables. This system actually consists of two systems; starting and working. The engine is started electrically using a starter motor powered by the airport power source or the on-board battery.

The engine is equipped with a two-circuit fire protection system. One circuit supplies neutral gas to the collectors located in the hot zone of the engine, the other is used to extinguish the generators.

In 1968, the Institute of Aviation received the First Prize of the Minister of National Defense for developing the SO-1 engine. In the same year, the team also received the honorary distinction Blue Wings.

TS-11 records.

On the TS-11-03 (-04) prototype in the fall of 1964, four world records recognized by the FAI were set in the class of aircraft with an empty weight of up to 3,000 kg. First record: on September 2, 1964. In a closed circuit 100 km. Warsaw-Tłuszcz-Kołbiel-Warsaw route. Speed 715.69 km/h Andrzej Abłamowicz. Second and third records: on September 24, 1964. In a closed circuit 500 km. Warsaw-Kraków-Warsaw route. Speed 730.70 km/h and closed circuit distance 510 km. Pilot Ludwik Natkaniec. Fourth record: on September 26, 1964, speed based on 15/25 km. Warsaw-Piaseczno route. Speed 830.00 km/h, pilot Ludwik Natkaniec.

Serial production of TS-11 Iskra aircraft.

The head of the design office established at WSK Mielec in order to implement the aircraft into series production was designer engineer Kazimierz Gocyła. Under his supervision, technical documentation for the serial aircraft was developed and production was launched under the designation TS-11 Iskra bis A. At the very beginning, an information series was prepared and transferred for trial use at the Air Force Training Unit. Thanks to the good cooperation of all stakeholders; The obtained results were taken into account and a number of corrections were made to the aircraft. It was at this stage that the wing tank leaks were dealt with. Engineers who participated in the work on improving the aircraft included: Jerzy Bar, Adam Borowski, Jerzy Kieroński and Ryszard Łęczycki. Preparations had been made to start production since 1962. A total of 54 units were built in 1964-1965 in 3 production series, from unit 1H 01-01 to 1H 03-22, powered by HO-10 engines.

Initially, there were cases of engine interruption in the air. Ground tests and various experiments could not clearly determine the cause. Since the plane, with the engine not running, has the ability to glide for a long time, or rather glide, ending with a successful landing, it was decided to look for the causes in flight. Civilian and military pilots in many flights determined the cause of this dangerous phenomenon. The failures were caused by a faulty fuel installation and the need to improve it.

In 1966, the first serial TS-11 Iskra aircraft equipped with the SO-1 engine was flown. The aircraft began to be delivered to the military in 1967. The fourth production series was the last series of the TS-11 bis A and also the first series with SO-1 engines. 15 machines were built.

The fifth production series was also the first production series of the TS-11 bis B version. The series consisted of 30 machines and was produced in 1968. A total of 103 serial machines were produced. The main difference between version A and B were 4 hardpoints.

The sixth production series of the TS-11 bis B consisted of 21 machines, giving a total of 124 aircraft. The series was also produced in 1968.

From 1969, aircraft with SO-3 engines left the factory. The seventh production series, 25 units built, was the first with SO-3 engines. A total of 149 machines were produced.

In 1970, 30 machines of the eighth production series were built, making a total of 179 machines.

In 1971, 22 machines of the ninth production series were built, giving a total of 201 machines. This completed the construction of the TS-11 bis B version.

Mistakes of the communist government.

The TS-11 Iskra entered production at a very special moment for the Polish Aviation Industry. Its production allowed the WSK Mielec factory to survive the difficult years caused by wrong decisions of the communist authorities, which stopped the development of the Polish Aviation Industry, and especially the use of Polish design ideas in the industry. The communist authorities, among other things, disbanded the excellent team of engineer Tadeusz Sołtyk, wasting his achievements. It should be assumed that these decisions were made under pressure from the Kremlin, because if this was not the case, it only proves scientific sabotage by the authorities. In these years, Mielec earned its living only from the production of TS-11 aircraft and An-2 light transport aircraft modernized by Polish designers. This is another reason why the TS-11 aircraft is so important for Poland.

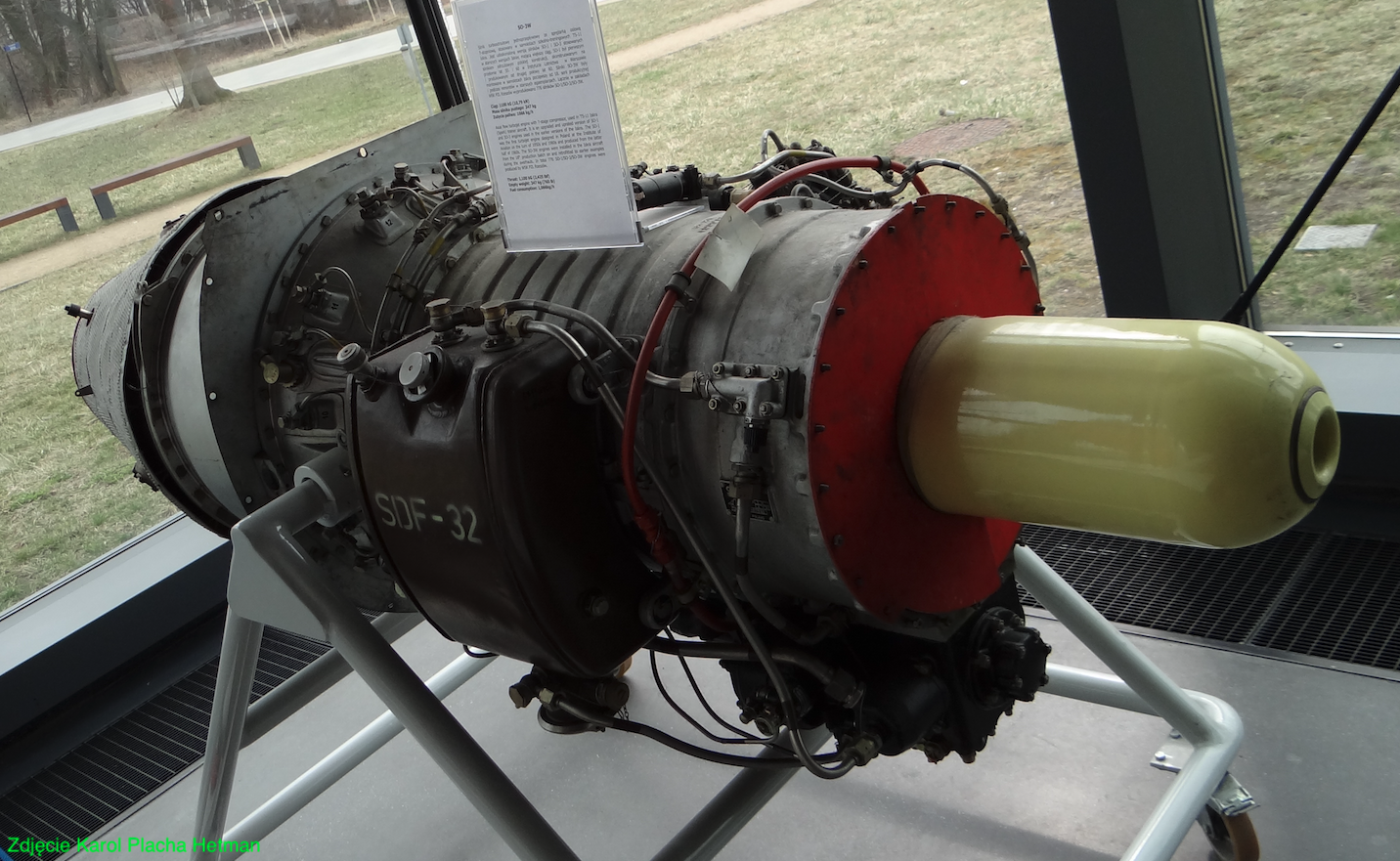

SO-3/B/W engine.

Thanks to the experience of employees from WSK Mielec, TS-11 Iskra obtained a very good drive. The engines became durable and reliable. They did not fail easily, even in situations where a foreign object was sucked in from the runway. There are known cases where a hare fell into the air catcher without causing the engine to stop working. It was decided to install special protective grilles on the air intakes. In subsequent years, only the lower parts of the grilles were used.

Around 1965, the SO-3 engine was introduced into production. It has the same thrust as the SO-1, but has an increased service life, up to 400 hours instead of the current 200 hours.

Changes were made to the SO-3 B engine, which allowed the take-off thrust to be increased to 1 x 1,080 kG. The changes consisted of making all compressor blades from steel and minor changes to the combustion chamber and turbine. There are no changes in external appearance compared to the SO-3 engine.

In 1979, a modernized engine designated SO-3 W with a thrust of 1 x 10.8 kN (1 x 1,100 kG) was developed and these engines powered the subsequent aircraft built.

Use of TS-11 Iskra aircraft.

TS-11 Iskra aircraft in the Polish Army have been used practically since the beginning of the uprising, and precisely since 1962, when military pilots were included in the tests. The first serial TS-11 aircraft received the OSL in Dęblin in 1964. The first months were used to conduct long-term tests, and only after them, when minor but necessary corrections were made, normal flight training began. Thanks to the introduction of modern TS-11 aircraft to the training in Dęblin, training on piston-powered aircraft was discontinued, leaving it only at LPW summer camps.

The main purpose of the aircraft is initial training on jet aircraft, training before flights on combat aircraft and learning and training in full aerobatics. The plane was equipped with shooting weapons, a photo gun, bomb suspension points, etc. (unguided missiles). Thanks to this, training in selected elements of tactical training can be conducted on the TS-11.

In the 1960s, the following system of training military pilots was established; TS-11, then SB Lim-2, Lim-5 and MiG-21 or Lim-6. TS-11 planes were also introduced into the equipment of combat units, where they were used for periodic training to consolidate the pilots’ acquired habits. The TS-11 aircraft is praised not only by pilots, but also by mechanics. Its operation is easy. All components and units are easily accessible. The units are easily dismantled. There is convenient access to instrument panels, avionics and weapons. The laminate cover on the front is easily removable. There is easy access to hydraulics and pneumatics in the wing fairings. There are sight glasses placed in good places on the rest of the plane’s fuselage. Replacing the engine takes little time.

Written by Karol Placha Hetman