Kraków 2017-11-14

About aviation fuels for curious people.

We have already published a lot of information on our website about airport petrol stations, cars, tanker-distributors and aircraft refueling. Likewise about aircraft engines; reciprocating and turbo-jets, in which this fuel is converted into energy. Therefore, now we present some information about aviation fuel itself.

Currently, aviation fuel is available in two basic types: fuel for turbojet (turbo-propeller) engines and fuel for piston engines. However, nowadays the base is turbojet fuel and commercial air transport and military aviation are based on it.

A more precise breakdown is as follows:

- Spark ignition piston engines run on aviation gasoline only.

- Compression ignition (diesel) piston engines run on diesel fuel.

- Turbine engines can run on: naphtha, broad-fraction fuels, aviation kerosene, diesel fuel, hydrogen, synthetic fuels.

Fuel for turbojet engines.

The vast majority of aviation fuels come from crude oil, which was originally called rock oil. The oldest existing oil well in the world is located in Poland in the village of Siary near Gorlice. The shaft was dug by hand in 1852 and started the extraction of crude oil in the mine established by Stanisław Jabłonowski. The first Polish crude oil mine was established in 1854 on the initiative of Ignacy Łukasiewicz in Bóbrka near Krosno. The first Polish crude oil distillation plant was established in 1856 in Ulaszowice near Jasło, and today it is within the city limits. One of the oldest refineries in the world, launched in 1884, is located in Gorlice.

It is worth adding that the emergence of the oil industry in the territory of the Republic of Poland also contributed to the launch of an air connection with Lviv.

At the beginning of the petroleum era, only kerosene was obtained from crude oil, which was commonly used for kerosene lamps, i.e. lighting. The rest of the crude oil was useless. It was only later that scientists became interested in the topic; What can be obtained from what is left? Various fractions began to be obtained from crude oil during distillation, which it was decided to use in various areas of the world economy.

The first Germanic turbojets, such as the Junkers Jumo 004, ran on a synthetic fuel known as "J2". This procedure was due not to the need for super fuel, but simply from a lack of crude oil to produce fuel. It turned out that gas turbines can work with a wide variety of fuels. They work on gasoline, diesel, kerosene, gas, hydrogen and many other fuels. The problem has developed in terms of security. Therefore, fuels with a higher flash point, which are less flammable and therefore safer to transport and operate, began to be used for turbojet engines. The second issue turned out to be the economic result, i.e. cost-effect. Gasoline turbojets have proved to be expensive to operate. As a result, most turbojets around 1945 were already running on kerosene or a mixture of kerosene and gasoline. The engine of the Soviet Yak-15 aircraft was started on gasoline, and then power was switched to kerosene. The UK relied on standards developed for kerosene llamas, i.e. lighting kerosene, also known as liquid paraffin. Practices for aviation gasoline have been used in the USA. The close cooperation between the UK and the US forced the first standards for fuel for turbojet engines.

The experience gained, and most of all the discovery that the fuel may freeze and cut the engine, forced the introduction of new standards. Minimum freezing points for particular types of fuel have been established.

In the 1950s, the US split fuel standards for commercial and military aircraft. ASTM International sets the standards for commercial aviation and all civil general aviation in the US. For military aviation, the standards are set by the United States Department of Defense, but these standards apply to all fuels that power turbojets, including those in commercial aircraft. This does not mean, however, that ASTM International has only been relegated to aviation gasoline. The organization has developed many methods, procedures and devices for testing all fuels, and these standards are valid in the Free World. The UK has developed its own standards for many years which are in fact consistent with those used in the US. Only the British Ministry of Defense has the power to issue standards in the UK.

Until 1980, there were no standards in the CCCP and satellite states. Turbo-jet fuel was called aviation kerosene, which was produced in CCCP refineries and was not subject to any control. Despite this, in Poland, throughout the period of the People’s Republic of Poland, it was possible to maintain chemical laboratories at fuel depots, and aviation fuels were subjected to good control. Especially in terms of water content and solid impurities. In 1980, in connection with the Olympics in Moscow, certain norms and standards for aviation fuels were introduced in the CCCP. Standards are included in GOST documents. Their basic aviation kerosene was designated RT and TS.

In the Free World, turbojet fuel is called ATF (Aviation Turbine Fuel) or AVTUR, and most often Jet fuel.

Features of aviation fuel.

Turbine fuel should have the following characteristics: low manufacturing cost, easy access, low fire risk, low evaporation pressure, high thermal stability, high calorific value, high specific heat. This fuel should also be: easy to move (pump), it should not block the filters with wax, ice and other chemical impurities, it should show no blocking of the lines with fuel vapors, it should be lubricating for pumps, it should be well sprayed in the injectors, precipitate little soot.

The parameters of turbojet fuel include; chemical composition, heat of combustion, calorific value, crystallization temperature, flash point, density, viscosity, volatility, theoretical air (oxygen) demand, thermal and chemical stability.

The main ingredients of all common fuels are the compounds: naphthalenes, paraffins, aromas and olefins. The latter are undesirable because they are a source of sediment and resins. There should be as few of them as possible.

In terms of weight, aviation gasoline is the lightest, followed by heavy gasoline, broad-fraction fuels, aviation kerosene and diesel, which is the heaviest. Aviation kerosene is about 10% heavier than gasoline. This is due to the lower content of volatile fractions.

Combustion heat and calorific value are the basic energy parameters of the fuel. They are calculated on the basis of the chemical composition of the fuel or determined experimentally. These values are also given in the heat tables.

The calorific value of a fuel is the amount of heat that will be released when a unit of volume of a given fuel is completely and completely burned, with the water remaining as vapor. In turn, the heat of combustion is the amount of heat that is released during complete and complete combustion of a unit of volume of a given fuel, with water remaining in the form of a liquid. The calorific value is always lower than the heat of combustion.

Since the basic types of fuel (aviation gasoline, naphtha, broadly fraction fuels, aviation kerosene and diesel fuel) have different specific gravities and different calorific values, it is difficult to indicate that this fuel is better and that is worse. They are generally similar to each other. Because those with a higher calorific value are heavier, so we will take less of it to the aircraft. However, the differences are not that huge. Therefore, the use of a given fuel is determined by other factors: price, ease of production, availability, safety, flash point, crystallization temperature. Generally, the heavier the fuel, the higher the ignition temperature, and much higher. Aviation gasoline ignites in negative temperatures (from -42 degrees C to -32 degrees C), and diesel fuel in positive temperatures (from 61 degrees C to 75 degrees C).

Depending on the distillation temperature of crude oil, we obtain different fuel. Aviation gasoline distills at 40-180 degrees C, wide fraction fuels 60-290 degrees C, aviation kerosene 130-280 degrees C, diesel oil 190-315 degrees C. However, it must be remembered that there are different crude oils and the percentages of individual fractions different. Therefore, the distillation temperature regimes can be narrowed or shifted upwards.

Jet fuel is obtained from the distillation of crude oil, it is the kerosene fraction distilling from 180 ° C to about 300 ° C. Kerosene is the main component of aviation fuel. The color of the fuel varies from colorless to straw.

It is also worth mentioning the thermal stability, which is the propensity of the fuel to release tars and other solid deposits under the influence of higher temperatures. This is especially important for supersonic airplanes due to the strong aerodynamic heating of the airframe.

There is also the chemical stability of the fuel, known as the resistance of the fuel to aging, especially during storage or in aircraft tanks under the influence of elevated temperature, the presence of oxygen or catalysing metal elements.

As aviation demand increased to more than 5% of all refined petroleum products, it was imperative that refineries optimize aviation kerosene production processes. The refinery columns specially adapted to the production of aviation fuel were created.

The quality of aviation fuel largely depends on the origin of the crude oil. In general, better fuel can be obtained from crude oil from Arab countries. This crude oil is less sulphated than the crude oil from the Moscow State or the North Sea. The sulfur contained in it plays a significant role in the quality of fuel. It is generally harmful to aircraft engines. However, it has not the worst lubricating properties.

Handling of aviation fuel.

The technical requirements and the handling of aviation fuel are described in the international JIG standards. (JIG – Joint Inspection Group). Added to this are the guidelines of the airlines (IATA – The International Air Transport Association). Compliance in terms of storage and handling is very often verified by various types of internal and external audits.

In theory, storing and transporting aviation fuel is not much different from handling automotive fuel as hazardous substances. The infrastructure must be adapted to the contact with aviation fuel and the size of the demand. Employees must have the appropriate certificates and training. Antistatic clothing must be worn in close proximity to storage tanks, installations, tanks and the fuel itself, while timely deliveries are ensured by appropriate planning and coordination of logistics activities.

The most commonly used fuels for commercial aviation are JET A and JET A-1, which are manufactured to an international standardized specification. The only other aviation fuel commonly used in civil aviation powered by a turbine engine is JET B, which is used for increased performance at low temperatures. This fuel is used in Canada and Alaska.

JET A.

JET A fuel has been used in the USA since the 1950s. They can also be found at several airports in Canada, such as Toronto and Vancouver. It is not available in other parts of the world. JET A fuel meets ASTM D1655 (Jet A) specification.

Basic JET A fuel data: Freezing point -40 degrees C, specific gravity 0.820 kg / l (6.84 lb / US gal) (it is usually slightly heavier than JET A-1), specific energy 43.02 MJ / kg (11.95 kWh / kg) (slightly higher than JET A-1), energy density 35.3 MJ / L (9.8 kWh / L) (slightly higher than JET A-1).

JET A-1.

JET A-1 aviation fuel is the basic fuel used in turbojet engines. It is available almost anywhere in the world, including at all airports in the US and Canada. JET A-1 aviation fuel is difficult to obtain in Moscow, where TS-1 fuel is offered as standard.

In JET A-1 fuel, the crystallization temperature coefficient must not be greater than -47 degrees C. −47 ° C (−53 ° F; 226 K), flash point 38 ° C (100 ° F; 311 K), boils at 176 ° C (349 ° F; 449 K), auto-ignition temperature 210 ° C (410 ° F; 483 K), density 775.0-840.0 g / l (which is definitely lighter than water). Both JET A and JET A-1 have a flash point greater than 38 ° C (100 ° F), with an auto-ignition temperature of 210 ° C (410 ° F).

Fuel for JET A-1 turbine aircraft engines is produced from components obtained in a specific technological regime in the processes of hydrodesulphurization, hydrocracking and distillation. The fuel is enriched with additives (anti-oxidation and anti-electrostatic).

In Poland, it meets the requirements of the ZN-ORLEN-18 Factory Standard "Fuel for JET A-1 Aero Turbine Engines", which is developed on the basis of:

- Aviation Fuel Quality Requirements for Jointly Operated System – AFQRJOS, Product Specifications Biulletin, Bulletin 96. Aviation Fuel Quality Requirements, issue 29 October 2016, Joint Inspection Group (JIG).

- British Defense Standard, British Ministry of Defense Document, Defense Standard 91-091 (DEF STAN 91-091), 9th edition of October 3, 2016 "Turbine Fuel, Aviation Kerosine Type, JET A-1. NATO Code: F-35 ”, Join Service Designation: AVTUR.

- ASTM D 1655-16a Standard Specification for Aviation Turbine Fuels.

- Must have IATA information material (kerosene type).

The main difference between JET A and JET A-1 is the crystallization temperature. JET A is -40 degrees C and JET A-1 is -47 degrees C. Another difference is the mandatory addition of an antistatic additive to JET A-1 fuel. Of course, tanks and cisterns have different pictograms.

The main advantage of using JET A-1 fuel is that it can be used all year round, without the need to follow the weather conditions. JET A fuel requires such control.

JET B.

JET B is an aviation fuel which has a very low freezing point. It is -60 degrees C (-76 ° F). This fuel is used in some military aircraft, as well as in northern Canada and Alaska. In fact, this fuel is a mixture of 30% aviation kerosene and 70% gasoline. This fuel also has a low flash point. Due to the high content of volatile fractions, it is dangerous to handle. In Moscow, similar fuels are also used for military aviation, precisely because of the low freezing point.

Military aviation kerosene.

In the Free World, air forces use fuel qualification marked as JP, meaning "Jet Propellant". Some of these fuels are almost identical to civil fuels. However, they may differ in additives. For example, JP-8 is almost the same as JET A-1. JP-4 is almost the same as JET B. Others are highly specialized fuels. They are mixtures of various chemical compounds combined with specific additives. These fuels are on the verge of space fuels.

In military aviation, according to NATO codes, the fuels used are F-35 (i.e. JET A-1), F-34 (JP-8), F-40 (JP-4), F 44 (JP-5). In the past, JP-1, JP-2 and JP-3 were also used.

JP-1.

JP-1 is the first turbojet fuel to be specified in late 1944 and approved by the US Administration. Another designation of JP-1 fuel is AN-F-32. It was popularly called Avtur. It had a pour point of -60 ° C (-76 ° F). The low required freezing point limited the availability of fuel and it was soon replaced by others.

JP-2 and JP-3.

JP-2 and JP-3 turned out to be unsuccessful fuels. They were developed in 1945. They were supposed to be easier to manufacture than the JP-1. First of all, they had a higher pour point. However, they were unstable due to the large proportion of highly volatile components. During storage, a large amount of fuel evaporated. They did not find wide application.

JP-4.

JP-4 was known as F-40 and AVTAG. It was a mixture of 50% kerosene and 50% gasoline. There were a few additives in the fuel. It had a lower flash point than the JP-1, but was preferred due to its greater availability. It was the main aviation fuel of the US Air Force in 1951-1995.

JP-5.

JP-5 is also marked as AVCAT and F-44. It was developed in 1952 especially for US NAVY aviation, and especially for aircraft carrier-based aircraft, where the risk of fire is greatest. Therefore, the flash point is at least 60 degrees C (140 degrees F). The pour point is -46 degrees C. There are several additives in the fuel. In order not to have two different fuels, the entire naval aviation adopted the JP-5 fuel.

JP-6.

JP-6 is a type of aviation fuel developed for the General Electric YJ93 turbojet engine of the XB-70 Valkyrie supersonic aircraft. The JP-6 was perfect for a high altitude bomber. It was similar to the JP-5, but with a lower freezing point and improved thermal stability. Freezing temperature -65 degrees C. After the XB-70 program was canceled, the JP-6, MIL-J-25656 specification was also canceled.

JP-7.

For the Pratt & Whitney J58 engine, which powers Lockheed SR-71 Blackbirds, a new fuel was developed, designated JP-7. JP-7 fuel was developed by Shell Oil in 1955 on the order of the Central Intelligence Agency for the Lockheed U-2 strategic reconnaissance aircraft. The fuel for the U-2 aircraft was marked JPTS.

JP-7 fuels are produced several hundred thousand liters per year on a special production line of Shell plants in the USA. The main feature of the fuel is its combustion stability and minimal evaporation at high altitudes, where the entire airframe heats up significantly. The story told by Ben Rich in his book, Skunk Works, is that a lit candle can be put in a JP-7 fuel bucket and the fuel will not catch fire and the candle flame will go out. In the SR-71 aircraft, the fuel cools the airframe surface, internal aggregates and devices, and is used as a lubricant for engines and other devices. Finally, having a temperature of around 550 degrees C, it is fed to the engine.

JP-7 is not a typical fuel that is made from the distillation of crude oil. JP-7 is a blend mainly consisting of hydrocarbons including alkanes, cyclo-alkanes, alkylbenzenes, indanes / tetralin and benzene, with the addition of fluoro-hydrocarbons to increase its lubricating properties, an oxidizing agent to burn it better, and cesium containing a compound known as A-50 that helped mask the plane from radar waves and reduced the infrared trace. JP-7 is virtually free from sulfur, oxygen and nitrogen which will contaminate typical fuel. Volatile matter is below 3%. The fuel must operate over a wide temperature range; from low temperatures that cause water to freeze at high altitudes to + 600 degrees Celsius. The SR-71 Blackbirds use approximately 36,000-44,000 pounds (16,000-20,000 kg) of fuel per hour of flight. "Cold" SR-71 fueled with JP-7 is leaking like a leaky burr. Therefore, it is not fully refueled. After take-off, the SR-71 quickly heats up and seals, meets a flying tanker and is fully refueled.

JP-7’s very low volatility makes it difficult to ignite. Chemical ignition is used to ignite them in the engine (combustion chamber and afterburner) of J58. For this purpose, tri-ethyl-borohydrogen (TEB), fed through injectors, are used. The SR-71 has a tank of approximately 600 liters (20.7 oz) for TEB on board. It provides approximately 16 times the start of engines and their afterburners. About 50 liters (1.7 ounces) of TBE are used for one ignition shot. TBE compound ignites spontaneously in contact with air at temperatures above -5 degrees C. The space above the TBE tank is filled with nitrogen. Besides, nitrogen plays an important role in the SR-71 aircraft. Even his tires are pumped with nitrogen.

Due to the use of TBE, the SR-71 aircraft has certain operational limitations. It is about the strength of the airframe, as well as the amount of fuel intake in flight, because then the plane must have the afterburners of the J58 engines turned off. Just refueling with TBE is extremely dangerous. The staff work in silver, flame-retardant overalls. On the other hand, refueling with JP-7 fuel is very safe and simultaneous servicing of the aircraft is allowed.

The J58 engine can also run on JP-4 and JP-5 fuels, but then the maximum flight speed does not exceed 1.5 Ma. Such power supply of the aircraft is treated as emergency and from virtually every flying tanker.

JP-8.

JP-8 is an aviation fuel widely used by the US military. It is specified by MIL-DTL-83133 and British Defense Standard 91-87. It was first introduced to NATO bases in 1978. Its NATO code is F-34. JP-8 is a fuel that is expected to remain in use until at least 2025.

JP-9.

JP-9 is a special fuel designed for missile gas turbines, in particular for the Tomahawk. This fuel was developed in the late 1960s. Containing TetraHydro Methyl Cycle-pentadiene TH dimer produced by catalytic hydrogenation of methyl pentadiene dimer.

JP-10.

JP-10 is a gas turbine fuel for missiles, in particular for ALCM. Contains a mixture of endo-tetrahydrodicyclopentadiene, exo-tetrahydrodicyclopentadiene and adamantane. It is produced by catalytic hydrogenation of dicyclopentadiene. It replaced JP-9 fuel, achieving a lower low temperature operating limit of -54 ° C (-65 ° F).

Fuel additives.

Turbojet engines are becoming more and more economical, they use less fuel giving more energy. At the same time, the pressure on environmental protection is increasing, which forces the reduction of the emission of harmful compounds generated in combustion processes. Due to the number and severity of the processes used, the use of additives is often necessary and sometimes compulsory. These additives can, for example, prevent the formation of harmful chemicals or improve the properties of the fuel to prevent faster engine wear.

The DEF STAN 91-91 (UK) and ASTM D1655 (international) specifications allow the addition of certain additives to aviation fuel, including;

Antioxidants added to prevent gumming, usually based on alkylated phenols, e.g., AO-30, AO-31 or AO-37. Antistatic agents to dissipate static electricity and prevent sparking; An example is Stadis 450 with dinonylnaphthylsulfonic acid (DINNSA). Corrosion inhibitors, e.g. DCI-4A used in civil and military fuels and DCI-6A used in military fuels. Fuel system icing inhibitors (FSII), e.g., Di-EGME; FSII is often mixed already at the point of sale so that users with heated fuel lines do not have to pay extra. Biocides are designed to suppress the growth of microorganisms (i.e. bacteria and fungi) present in aircraft fuel systems. Currently, two biocides are approved for use by most original aircraft and turbine engine (OEM) manufacturers; Kathon FP1.5 Microbiocide and Biobor JF. A metal deactivator may be added to correct for the detrimental effect of trace metals on the thermal stability of the fuel. The only permitted additive is N, N’-disalicylidene 1,2-propanediamine.

Water in fuel.

It is very important that aviation fuel is free from water contamination. During the flight, the temperature of the fuel in the tanks drops due to the low temperatures in the upper atmosphere. This causes the dissolved water to be precipitated from the fuel. The precipitated water then sinks to the bottom of the tank because it is heavier than fuel. Since the water is no longer in solution, it can form droplets that can solidify into ice. Aviation history knows cases of ice disasters in fuel lines.

It is not economical to remove all the water from the fuel; therefore, fuel heaters are used in commercial aircraft to prevent water from freezing in the fuel.

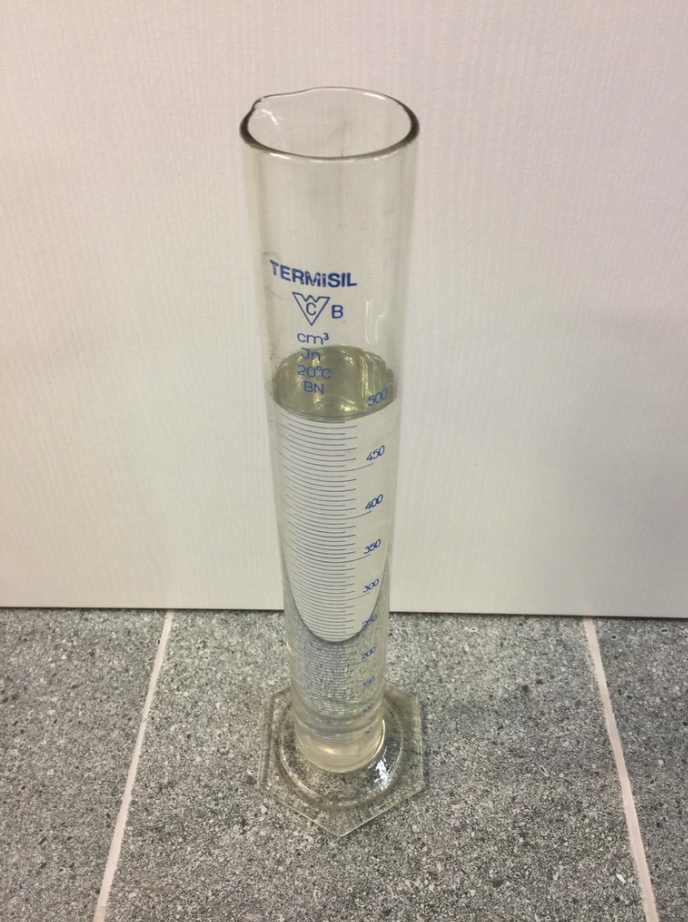

There are several methods for detecting water in turbojet fuel. The visual inspection can detect high concentrations of water in the fuel as it makes the fuel turbid. The industry standard chemical test to detect free water in turbojet fuel uses a water sensitive filter element that turns green if the fuel exceeds the specification limit of 30 ppm (parts per million) of water. A test to evaluate the ability of a fuel to release emulsified water after passing through coalescing filters is the ASTM D3948 Standard Test Method for Determining Water Separation Characteristics of Volatile Turbine Fuels Using a Portable Separator.

Aviation fuel availability.

Worldwide demand for aviation fuel has increased steadily since the Great World War. After the great fuel crisis of 1973, the demand for aviation fuels has been systematically growing. Over the past 30 years, consumption has more than tripled. In 1980 it was 1,887,000 barrels per day, and in 2010 as much as 5,220,000 barrels per day. About 30% of the world’s aviation fuel consumption comes from the USA (1,398,130 barrels per day in 2012).

Environmental protection regulations many years ago banned the use of leaded automotive fuel, as lead released into the atmosphere and absorbed by the human body promotes the development of neoplastic diseases. Therefore, the search for alternative fuels and engines for General Aviation began. It has been noticed that aviation kerosene is very similar to diesel fuel. Under certain conditions, aviation kerosene can be burnt in diesel engines. As a result, several aircraft engine manufacturers, most notably Thielert and Austro Engine, began offering aviation kerosene diesel engines. The problem is that few diesel engines have obtained aviation certification. Diesel engines are rare today in aviation, despite the fact that engines of this type (eg Junkers Jumo 205) were used during World War II.

Switching from general aviation (reciprocating engines) to diesel would reduce the range of aviation fuels and thus increase the availability of those that would remain in use. However, it must be remembered that diesel engines are more expensive to produce, operate and repair. In addition, great politics enters into it all. General aviation aircraft are more likely to switch to automotive fuels, ie unleaded gasoline.

Aviation kerosene is very often used in airport ground handling vehicles instead of diesel fuel. For example, this is what the USAF troops are doing using JP-8 fuel. However, this fuel has poor lubricating properties compared to diesel fuel. Aviation kerosene has a low cetane number of around 45, the requirement for diesel fuel is a minimum of 51. Therefore, breakdowns of this equipment occur more frequently.

Generally aviation kerosene is more expensive than diesel fuel. This does not result directly from the production technology, but from rigorous standards, procedures, tests, multiple inspections, etc. Sometimes, for logistical reasons, one fuel is replaced with another, but not in aircraft.

Shell Aviation is a leader in the sale of aviation products and in the management of refueling infrastructure at airports. Every day, Shell Aviation supplies over 87 million liters of aviation fuel to approximately 20,000 aircraft at over 800 airports in 90 countries around the world.

Synthetic fuels and biofuels.

The history of synthetic fuels in aviation is as old as the history of aviation.

In recent years, a synthetic fuel known as Fischer-Tropsch (FT) has appeared. Under certain conditions, this fuel can be made from seawater and its algae. Laboratory work confirmed the possibility of obtaining such fuel. In the US, the military was keen on its certification. FT fuel would be blended with JP-8 in a ratio of 50% to 50%.

In general, synthetic fuels are used as additives to classic fuels. Their good influence on the reduction of pollutants such as SOx, NOx, solid particles and sometimes carbon reduction was noticed. Its use is suspected to reduce the level of harmful compounds in the atmosphere near airports.

Biofuels are also an alternative to fuels derived directly from crude oil. They are often referred to as "Green Jet Fuel" for advertising, which is not entirely true. These fuels were obtained from sea algae, bamboo nuts, coconut, sunflower, rapeseed and many other oilseeds. Biofuels have been and are experimentally adjusted. They were used as additives from about 20% to 80% to normal aviation kerosene. The main goal was to find alternative fuels in the event of an armed conflict.

Aviation fuels in Poland.

Generally, at Polish airports we can use two fuels: JET A-1 for turbine engines and AVGAS 100 LL for piston engines with spark ignition.

The demand for aviation fuel in Poland is definitely growing, which we can observe from year to year. However, it should be remembered that the high dynamics results from the low level of development of the aviation market in Poland.

Fuels for reciprocating engines.

Users of small aircraft with piston engines have repeatedly asked questions – Is it possible to pour car gasoline into the plane? They never ask the question – Is it safe? Formal reasons leave no room for doubt. They are defined by relevant regulations and instructions for the operation of means of transport. The operating instructions are closely related to and result from technical conditions. So the question seems unfounded. But there are no stupid questions. There are only stupid answers. Therefore, it should be stated that aviation fuels do not contain oxygen compounds (alcohols and ethers), unlike motor gasoline, which may contain such components. In addition, aviation fuels contain such additives that are to ensure failure-free and possibly long-lasting operation of the aircraft engine in all conditions. There are strict, stringent standards and specifications for aviation fuels that do not exist for gasoline.

There are different grades of AVGAS fuel, but for calculations that do not require high accuracy, it is assumed that AVGAS has a density of 0.721 kg / dm³.

Specifications of currently produced AVGAS grades have not changed since the 1940s, when both the military and airlines used supercharged engines with high sensitivity to detonation and pre-ignition. Currently, the use of lead tetraethyl is limited to the minimum required by the specification of a given fuel due to the harmfulness and high production cost of this compound. Most Lycoming and Continental engines were designed in the 1950s / 1960s with the aviation fuel specifications of the time in mind, therefore it is not possible to safely replace AVGAS with unleaded fuels. At least until a replacement meeting the same standards is developed.

Nay. For gasoline car engines, regardless of the manufacturer, we can pour Ethylin 95 or Ethyl 98, and in the 80s – Ethyl 76. Aviation is a bit different. For various reasons, there are several types of aircraft piston engines. This entails the existence of several commercial grades of aviation gasoline.

Aviation gasoline types.

- Low lead (grade 80/87, grade 80, AVGAS 80) lean octane> 80 and rich octane> 87. This gasoline is colored red.

- Low lead (grade 100 LL, grade 100/130 LL, AVGAS 100 LL) with lean octane number> 100 (> 99.5) and performance index> 130. These gasolines contain, respectively, max. 0.56 g lead / liter where one gram of lead tetraethyl contains 0.6 g lead. Currently, it is the most popular fuel. Its name is an abbreviation of the English "low lead". The composition is defined by the ASTM D 910 and DEF STAN 91-90 standards. AVGAS 100LL is colored blue.

- Lead (grade 91/98, AVGAS 91) lean octane> 91 and rich octane> 98. This gasoline is colored brown.

- Lead (grade 100, grade 100/130, AVGAS 100) with lean octane number> 100 (99.5) and performance index> 130. The composition of AVGAS 100 (sometimes also called 100/130) follows the ASTM D 910 standard, as does 100LL. The standard for lead tetraethyl content for AVGAS 100 is 1.12 g / l, which is twice as high as for 100LL, which is why it has now been practically superseded by it. Due to the high lead content, it can also accelerate the accumulation of pollutants in engine cylinders. AVGAS 100 is colored green.

- Lead-free (grade 82 UL (82 UL) – unlea-ded aviation gasoline) with lean octane number> 82.0. This gasoline is colored purple.

- Lead aviation gasoline B 91/115 is intended for ASz-62IR and Ivchenko AI-14 radial engines. The properties of B 91/115 aviation gasoline are determined by the Russian standard GOST 1012-72. The motor octane number is min. 91, and the performance number min. 115. Exceptions, this gasoline has a high lead content. The lead content is max. 1.6 g / l and the tetraethyl lead content is max. 2.5 g / kg. It is colored green.

- UL 91 (91 UL) lead-free aviation gasoline is manufactured in accordance with ASTM D 7547. It is used in Rotax and Lycoming engines listed in the Lycoming Service Manual SI1070R. This gasoline is colorless, ethanol free, and contains antioxidant and antistatic additives.

- UL 85 (UL 85) lead-free aviation gasoline is used to power aviation piston engines in ultralight aircraft. The product meets the requirements of the PN-EN 228 standard and does not contain oxygen compounds. The motor octane number is min. 85, and research min. 95.

Other aviation gasoline was also produced in the USA and Europe, but is no longer available on the market.

AVGAS – The name comes from the English language, from the combination of the words "aviation gasoline".

In Poland, for logistical reasons, only AVGAS 100 LL fuel, the so-called blue fuel, with the NATO F-18 code, is widely available. It is a gasoline with a relatively low lead content and, at the same time, good resistance to knocking combustion, both in normal and extreme operating conditions of the aircraft engine. It can be used in all engines, except for those where the manufacturer prescribes the use of unleaded fuel only.

One of the most important parameters of the types of motor gasoline is the octane number, defined as an indicator of the resistance of gasoline to detonation combustion in spark ignition engines. The cause of detonation in the engine is too rapid combustion process. Detonations damage the engine. First, the bushings and the crankshaft are damaged. Then valves, pistons and connecting rods. By convention, the detonation resistance of n-heptane was assumed to be 0, and the detonation resistance of isooctane (2,2,4-thymethylpentane) to be equal to 100. The octane number was determined in standard, single-cylinder engines with variable compression ratio.

An additional anti-detonation parameter of aviation gasoline, unlike motor gasoline, is the so-called performance number. The performance number is an indicator of aviation gasoline resistance to detonation in spark ignition engines operating on a rich mixture. It allows to determine the percentage of the power developed by the aircraft engine.

AVGAS also has a lower vapor pressure than automotive fuel due to the need to remain liquid under reduced atmospheric pressure at high altitudes where airplanes fly, otherwise there is a risk of a phenomenon known as vapor jam.

In addition to the appropriate octane numbers, aviation gasoline must meet several other physicochemical parameters characterizing volatility, energy value, low-temperature properties, resistance to aging during storage, no contamination or corrosive effect on metals. The volatility of gasolines determines the process of its evaporation, the formation of the air-fuel mixture and the combustion process, and is determined by the fractional composition and vapor pressure.

Let’s not forget about an important parameter, which is the freezing temperature. For aviation fuel, it cannot be higher than -58 degrees C. Below this temperature, the process of ice crystals precipitation from gasoline begins, and this may clog the fuel lines.

Added to all this is the presence of water in the fuel and the interaction of gasoline with water vapor. The alcohol content of aviation gasoline (mainly ethanol) is unacceptable due to the risk of phase separation in the presence of water. The volume of the water layer must not exceed 2 ml per 100 ml of fuel. Gasolines containing water or solid contaminants tend to accumulate static electricity. This can cause electrical discharges and an explosion of fuel vapors. This is especially dangerous in aviation. Therefore, anti-electrostatic additives are added to aviation fuels and the electrical conductivity of the fuel is controlled. The amount of these additives and the value of electrical conductivity are strictly defined in the standards.

Car gasolines used today in the EU countries do not contain lead compounds. The necessity to eliminate lead compounds from the composition of automotive gasoline, due to the promotion of neoplastic diseases, resulted in the need to replace them with other ingredients improving resistance to knocking combustion. These other additives caused the deterioration of some properties of Ethylin: lower energy value, reaction with water, harmful swelling of the seals, deterioration of the lubrication conditions of the valve seats and their faster burnout, and a deterioration of fuel stability during storage. Automotive and aviation gasolines differ both in composition and in a number of physicochemical parameters. The chemical composition of automotive gasoline is selected in such a way as to ensure correct, failure-free and possibly long-lasting operation of the car engine.

Besides, aircraft engines are very different from car engines, although they operate on the same principle. They work at higher revs, with higher loads and at higher temperatures than a car engine. Only 2-5% of their working time is idle.

Overall, the production cost of aviation fuel for reciprocating engines is higher than that of automotive fuels. This is due to, inter alia, lower demand for these fuels. For example, in Poland, the aviation gasoline market is only 0.1%. For this reason, aviation gasoline is not produced at most refineries. There are only four producers in Europe, and among them in Poland – OBR SA in Płock.

Most importantly – the purpose of the fuel and the scale of the effects of the smallest deviations of the physicochemical parameters of fuel from the standards, impose a huge responsibility on producers and suppliers of aviation fuels, which translates into the development and strict application of safety procedures for handling these products.

Written by Karol Placha Hetman