Kraków 2020-10-28

Turbojet engines RD-500, RD-45.

The article describes the RD-500 and RD-45 turbojet engines, copied by CCCP from British designs, and also mass-produced in Poland, under a Russian license.

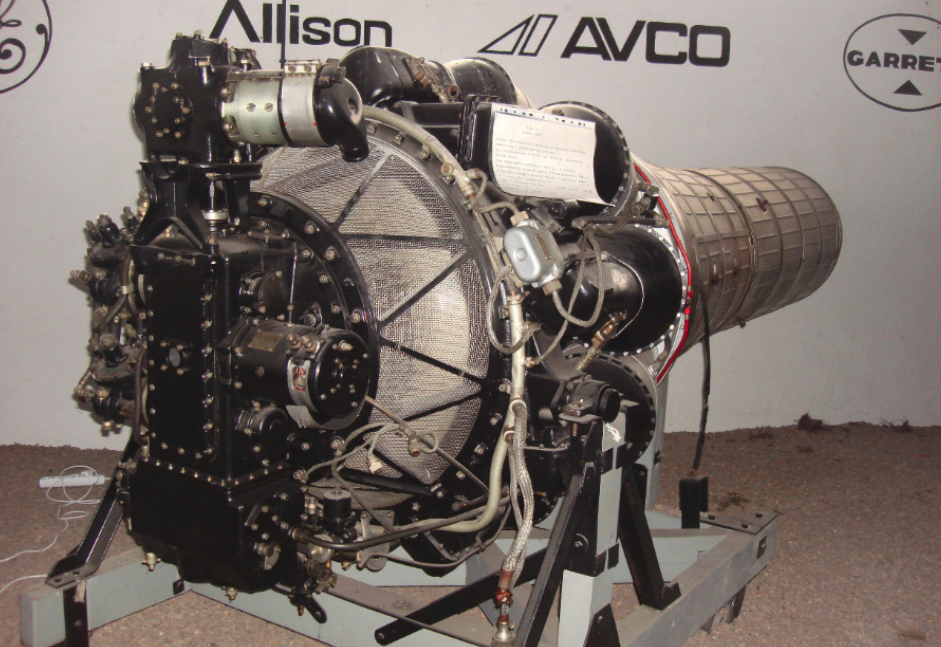

Description to the photo: Russian RD-500 engine used in the Yak-23 fighter plane. The Jak-23 planes were in service with the Polish Army in the 1950s.

RD-500, RD-45 engines. 1947 year.

The number of new CCCP turbojet designs in the period 1946-1947 was large. However, they all had a major disadvantage – the extremely short flight time, and therefore a short range. Even for the frontline planes, these parameters were difficult to accept. In the UK and the US, the performance was much better. Therefore, in March 1947, new air force requirements were presented. High-altitude per sonic speed (1,000 km / h), strong armament, flight duration about 1 hour, range 1,200 km, air-tight cabin, application of air brakes, use of a chassis with a front wheel. Above all, a new engine was needed to meet these requirements. The RD-10 and RD-20 engines produced in series would not be able to drive new constructions. The Lulk TR-1 engine was also unsuccessful.

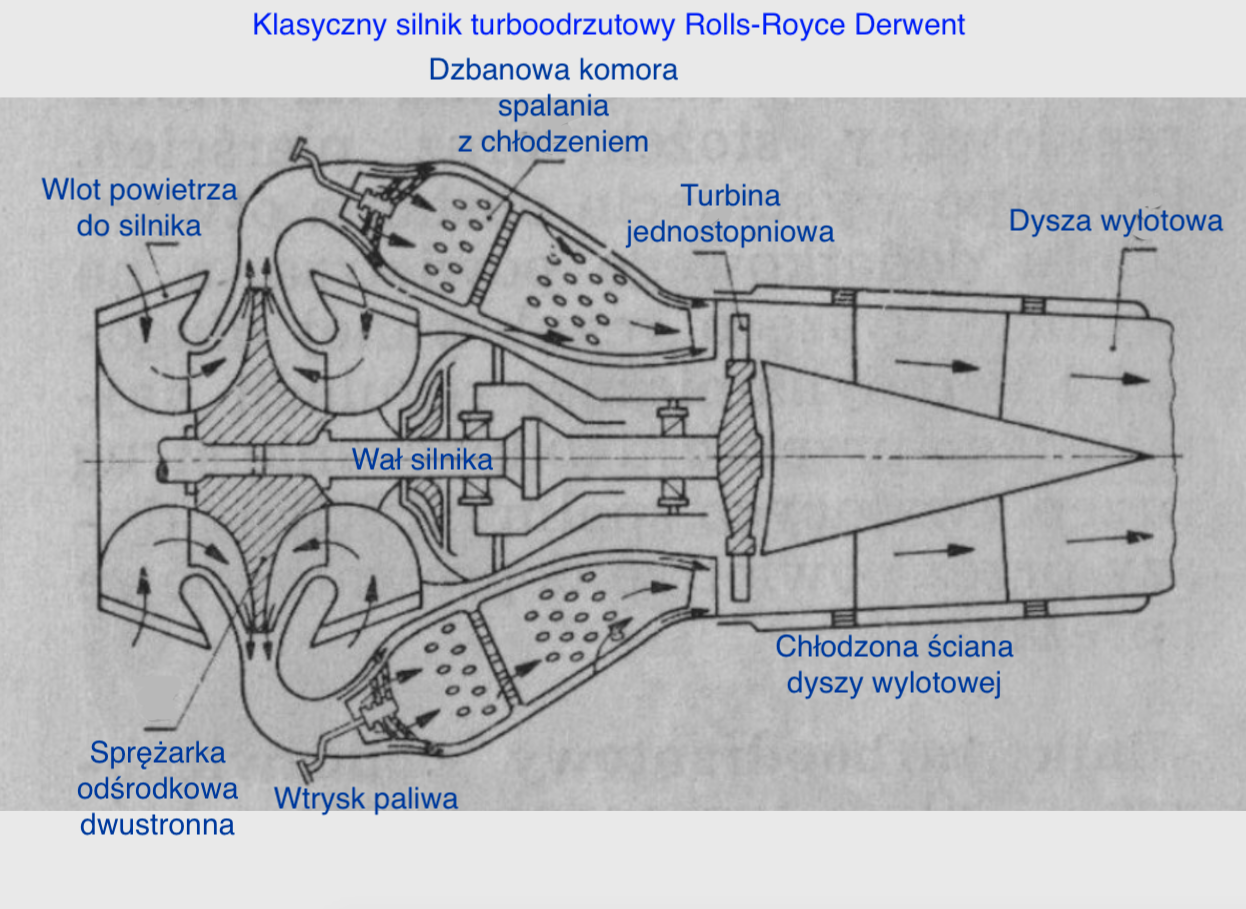

The situation in the world development of turbojet engines was closely followed by Soviet intelligence. All the information went to Artiom Ivanovich Mikoyan, a famous aircraft constructor at the time and Stalin’s favorite next to Yakovlev. Nay. Artiom Mikoyan was the brother of Anastas Mikoyan, a member of the political bureau who was Stalin’s right-hand man, and then Khrushchev’s faithful subjects. In 1946, Rolls-Royce put its Derwent V and Nene I / II engines for sale. On June 17, 1946, a decision by the CCCP Council of Ministers was issued allowing the purchase of these engines in the UK. Then a delegation was sent to Great Britain. It included: Artiom Ivanovich Mikoyan – aircraft constructor, Vladimir Yakovlevich Klimov – engine constructor, S. T. Kiszkin – technologist-metallurgist. The delegation stayed in England from December 3, 1946 to December 22, 1946. (Vladimir Klimov stayed there until February 1, 1947). Much was not expected. Relations with recent allies worsened. However, the English wanted to sell engines. The Russians visited the following plants: Bristol, de Havilland, English Electric, Gloster, Metropolitan-Vickers, Rolls-Royce and Vickers-Armstrong. The detailed report was submitted to the political office of the central committee of the communist party of the Soviet Union, abbreviated as the Politburo of the Central Committee of the CCCP, or "Politburo", on January 10, 1947. It contains information about the large financial resources invested in the development of turbojet engines. The success of the creep resistant Nimonic-80 superalloy was presented. Reliability and long life of the Derwent V and Nene I engines were emphasized. Ease of operation and repairs were emphasized. It was also recorded that the German achievements were far more modest than the current British successes.

RD-500.

In such a situation, these engines had to be purchased at all costs, or obtained in other countries and then copied. The party materials did not hide that it was planned to copy the engines without buying a license. The purchase agreement was approved by the CCCP on March 11, 1947. On March 21, 1947, the first 10 Derwent V engines left England for Murmansk. Another delivery: 20 Derwent V (15.6 kN line, 125 hours service life between overhaul) and 15 Nene I (22.3 kN line) reached Murmansk in November 1947. According to other data, 30 Derwent V and 25 Nene I / II engines were purchased.

Much earlier, on February 15, 1947, a secret decision was made to copy the Derwent V and Nene I / II engines. The licenses were not sold to the Russians, but the documentation of the engines obtained by the intelligence did come into their hands. The fact that these engines were copied without a license was discovered in 1958, during a visit to Beijing by the pilot Whitney Straight, who was viewing the MiG-15 plane there. He was then on the board of the Roll-Royce concern. He decided to take the CCCP government to court, seeking compensation for infringement of £ 200 million, which never happened.

Looking through the current English Internet forums, one can notice the criticism of the post-war UK government for this sale. It is believed that the CCCP would take at least five years to develop a Rolls-Royce Nene-sized engine, and therefore there would be no MiG-15 fighter. Their first Lulk TR-1 engine was unsuccessful. However, it should be mentioned here that the purchased engines were used in the aviation of several countries at that time. They were not, so they are secret. The sale was a gesture of goodwill for non-military use, which we personally consider to be British naivety. Britain has never made this mistake again. On the other hand, it is not known whether the Russians would have acquired these engines in a different way, in another country.

Mikoyan chose a more powerful but heavier engine for his future fighter. It took a long time to choose the concept of the future aircraft. However, Mikoyan certainly wanted to avoid the troubles that accompanied the MiG-9 fighter. He gave up the two-engine system. He resigned from the outlet nozzle under the fuselage, considering it unforeseen. For a long time he maintained a concept similar to the English Vampir, but with a slanted wing. As for the wings, he had no doubts whatsoever. They were supposed to be oblique.

The Rolls Royce Derwent V engine had a very favorable thrust to weight ratio, which made it suitable for the propulsion of light fighter aircraft with high climb rate (thrust to weight ratio was 0.0316 kN / kg or 31.871 kg / kN). Max thrust of 17.79 kN at 15,000 rpm at sea level. (Idle 0.53 kN at 5,500 rpm). It is 2.249 m (88.5 in) long, 1.092 m (43 in) in diameter and weighs 567 kg (1,250 lb). Single-stage, two-way, centrifugal compressor with a pressure of 3.9: 1. 10-pitcher combustion chambers. One-stage turbine. Gas temperature before the turbine 849 degrees C. Fuel – aviation kerosene (kerosene) type R.D.E.F./F/KER. Fuel consumption 103.97 kg / kN / h. Oil system with cooling and oil filtration.

In CCCP, the group of Vladimir Klimov took care of the Rolls Royce Derwent V engine. The engine received the designation Klimov RD-500. English documentation was prepared for Soviet manufacturing technologies and materials. The first engine start-up took place on December 31, 1947. The engine became the main propulsion of the Jak-23. Jak-23 planes were operated in Poland. About 859 Klimow RD-500 engines were built at CCCP.

The problem with the RD-500 engines was the lack of the original Nimonic-80 alloy, which was developed in 1940 by the Wiggin Works research team in Hereford, England, specifically for Frank Whittle engines. Nimonic-80 is a high temperature superalloy characterized by a low creep value. Creep is a slow change in the shape of the material (deformation) as a result of the action of constant, long-term loads smaller than the material elasticity limit. Creep is much faster at high temperatures. Nimonic-80 is an alloy based on nickel (about 50%) and chromium (about 20%) with additives such as titanium and aluminum. The Russians used the KhN 80T alloy, which deformed much faster due to the high creep factor.

The RD-500 engine had other serious problems. Uneven combustion and cracking of the combustion chambers. Uneven combustion was the result of modification (simplification) of the fuel system by Soviet engineers. The Russians made one more major change in the construction of the engine. Instead of 10-pitcher combustion chambers, they used 9-pitcher combustion chambers slightly larger. This was the cause of their cracking initially. The problems were resolved in September 1948, when the engine successfully passed the state test of 100 hours of continuous operation. It was then decided that the engine could be put into service with an overhaul service life of 100 hours.

The Klimow RD-500 engine compared to the Rolls Royce Derwent V engine had a lower thrust by as much as 1.89 kN. RD-500 thrust 1 x 15.90 kN (1 x 1 590 daN) at 14 700 rpm (245 rpm) at sea level. It has the same diameter (1.09 m), but is slightly shorter due to the shorter nozzle (2.06 m). However, it has a greater weight of 14 kg (581 kg). It also had a higher fuel consumption of 140 kg / kN / h, due to its inferior quality. As a result, the thrust to weight ratio was 0.0273 kN / kg, or 36.540 kg / kN.

During the production of Klimow RD-500 engines, the main problem was defective castings of the turbine blades. More than 30% of the castings were rejected. In turn, during operation, the blades made of the KhN 80T alloy elongated and the turbine was damaged. The RD-500 engines rarely worked the declared 100 hours of operation between overhauls. The Russians also had big problems with the organization of work during the production of RD-500 engines. In 1947, initially as much as 20,000 man-hours were required to produce one engine. That figure dropped to an acceptable 7,900 person-hours by November 1947. In March 1949, 4,700 person-hours were achieved. Factory No. 500 in 1948, built 97 engines, and in 1949 – 462. Production was also placed at the factory No. 16 in Kazan, where in 1949, about 300 RD-500 engines were built. A total of 859 engines were built. Production of Klimow RD-500 engines was stopped in 1950, in favor of Klimow WK-1 engines built on the basis of the Rolls-Royce Nene engine. In CCCP, the Klimow RD-500 engine was used to propel aircraft; Yakovlev Yak-23, Yak-25, Yak-30, Yak-1000, Lavochkin La-15, Mikoyan and Guriewicz KSK, Raduga KS-1 Komet. The Klimow RD-500 engine was copied in China and developed at Shenyang Aircraft Development Office PF-1A.

RD-45.

The second engine captured in England was Rolls Royce Nene. These were basically two Rolls-Royce Nene Mk 1 and Mk 2 engines that were the first versions of this family. Rolls-Royce Nene is part of the third series of centrifugal turbojet engines following the Wellend and Derwent development lines built at Rolls-Royce. These engines were replaced by engines of the Avon family with axial compressors. The Rolls-Royce Nene engine was used on Avro Lancastrain aircraft in place of two Merlin type external piston engines. They were also used on the Lockheed XP-80 Shoting Star. In 1947, license production was started in the USA at the Pratt and Whitney plants under the designation J-42 and was used to power, among others, Grumman F9F Phanter fighters. Rolls-Royce Nene and Pratt and Whitney J-42 engines were used to power over 25 aircraft structures.

The Rolls-Royce Nene I / II engine has been significantly enlarged compared to the Rolls-Royce Derwent V. Its first launch took place in 1944. The Rolls Royce Nene engine received 9-pitcher combustion chambers. Thrust 1 x 22.24 kN at 12,300 rpm at sea level. (Idle 0.53 kN at 2,500 rpm). Engine dimensions; 2.458 m (96.8 in) long, 1.257 m (49.5 in) diameter, weight 726 kg. The thrust to weight ratio is 0.0306 kN / kg, or 32.643 kg / kN. These are worse parameters than the Derwent V engine, but the greater thrust cannot be overestimated. Fuel – aviation kerosene (kerosene) type R.D.E.F./F/KER. Fuel consumption 108.04 kg / kN / h. Oil system with cooling and oil filtration. The engine turbine simultaneously drives the generators and the high-altitude compressor.

The Rolls-Royce Nene engine in CCCP received the designation RD-45 because it was produced at the No.45 plant. Production was also started at the GAZ 116 plant. Initially, the RD-45 engines had the same problems as the RD-500 engines.

On December 30, 1947, the MiG-15 fighter, powered by the RD-45 F engine, was flown, and shortly after it, on January 8, 1948, the La-15 (La-174) fighter with the RD-500 engine. These planes were built in a modern arrangement with oblique wings and had similar high performance (MiG-15 – speed 1047 km / h, La-15 – 1026 km / h). The MiG-15 went into mass production, becoming the most numerous jet aircraft in history (about 12,000 of all versions and several thousand more licensed), while the La-15 was built in a limited number for one fighter regiment. Even before them, the Yak-25 aircraft was developed in the OKB Yakovlev office, it flew on October 31, 1947 (the first of this name), but due to the use of straight wings, it had lower performance and did not enter serial production.

The Klimov RD-45 engine seemed to the Russians more perspective, due to the greater thrust, despite its greater dimensions and weight. Therefore, it was modified. The size of the pitcher combustion chambers has been increased, the turbine has been enlarged and the airflow through the engine has been increased from 41 kg / s to 45 kg / s. This is how the WK-1 engine (Vladimir Klimov) was created, which later received an afterburner. The WK-1 F designation was changed. The WK-1 engine became the propulsion of the MiG-15 bis and Il-28 aircraft, and the WK-1 F engine of the MiG-17 aircraft.

The WK-1 engine has dimensions; length 2.60 m, diameter 1.30 m, weight 872 kg. Double-sided centrifugal compressor. Compression 3.1: 1. Max thrust 26.5 kN (2,702 kG) at 13,000 rpm at sea level. Fuel consumption 109.1 kg / kN h. The thrust to weight ratio is 0.0303 kN / kg or 32.95 kg / kN.

Production in Poland of Lis-1, Lis-2, Lis-5 engines. 1955 year.

The RD-45 F engine was produced in Poland at WSK PZL Rzeszów under the designation Lis-1. The designation Lis stands for – license engine. Poland paid the Russians for the license, and as stated above, the CCCP did not pay the British for the licenses. The license was bought in 1955. The Lis-1 engine has a thrust of 1 x 22.25 kN (1 x 2 270 kG). However, relatively quickly this engine was replaced on the production line with the WK-1 engine, which was designated Lis-2 in WSK PZL Rzeszów.

Basic data of the Lis-2 engine: Production at WSK PZL Rzeszów. Maximum thrust of 26.5 kN (2,700 kgf) at 11,600 rpm. Compression ratio 4.0: 1. Engine weight 872 kg. The engine has a double-ended centrifugal compressor, 9 combustion chambers, single-stage turbine. The temperature behind the turbine is 720 degrees C. Fuel consumption 1,050 g / h / kG.

After the production of Lim-5 (MiG-17 F) and Lim-5 P (MiG-17 FP) fighter planes in Poland, the production of WK-1 engines with an afterburner was also launched for this aircraft. In Poland, the engine was designated Lis-5. This engine was also used to power Polish Lim-6 aircraft.

Lis-5 engine with 1 x 26.46 kN (1 x 2 700 kG) thrust, and 1 x 33.12 kN (1 x 3 380 kG) with afterburning. The afterburner is connected to the engine and constitutes an extended and suitably formed exhaust pipe. There is a set of injectors through which additional fuel is supplied, and burning it causes an increase in thrust. The fuel to the engine is supplied by the PCR-1-5 pump.

Basic data of the Lis-5 engine: Production at WSK PZL Rzeszów. Identical to the Lis-2 engine, only the afterburner was added. The thrust without afterburning is 2,650 kG at 11,560 revolutions per minute. The afterburning thrust is 3,380 kgf at 11,560 rpm. Engine weight 978 kg. Fuel consumption without afterburning 1.5 kg / kG / h. Fuel consumption with afterburning 1.8-2.0 kg / kG / h.

Written by Karol Placha Hetman