Lublin 2016-01-14

The airport and aviation plant in Lublin in the Second Polish Republic.

E. Plage and T. Laśkiewicz Mechanical Works in Lublin.

Geographic coordinates: 51.236N 22.583E. Elevation 180 m.

History

Zakłady Mechaniczne Emil Plage i Teofil Laśkiewicz in Lublin is the first Polish Aviation Factory. The plant had been producing aircraft since 1921. From 1928, he produced his own structures under the name Lublin. The plant was nationalized in 1935. On September 1, 1939, Germanic troops invaded Poland, starting World War II. On September 17, 1939, the Germanic troops were helped by the Soviet troops, their brothers. With the fall of the Republic of Poland in September 1939, the aircraft factory in Lublin also went bankrupt.

Prologue

The Plage family probably came from Belgium. They were Protestants by religion. In 1860, Albert Plage opened a metal workshop at Bernardyńska Street in Lublin. Bernardyńska Street still has the same name and is the exit street from Lublin towards Żmigród. The workshop began producing copper sheet vessels, which were popular at that time. Plates, bowls, pots and equipment for distilleries were produced. The workshop developed and at the end of the 19th century it employed about 50 people. The workshop then changed its name to "Albert Plage’s Copper Products Factory". At that time, the plant also started producing iron products. In 1897, Albert Plage handed the plant over to his son Emil Plage, who turned out to be even more enterprising. Already in 1899, the plant employed about 90 people.

Teofil Emeryk Laśkiewicz was born in 1869 in Skierniewice and was a Polish industrialist and technologist. He was comprehensively educated in technical fields. He was professionally associated with Łódź, Warsaw, St. Petersburg and Odessa. In 1898, he moved to Lublin.

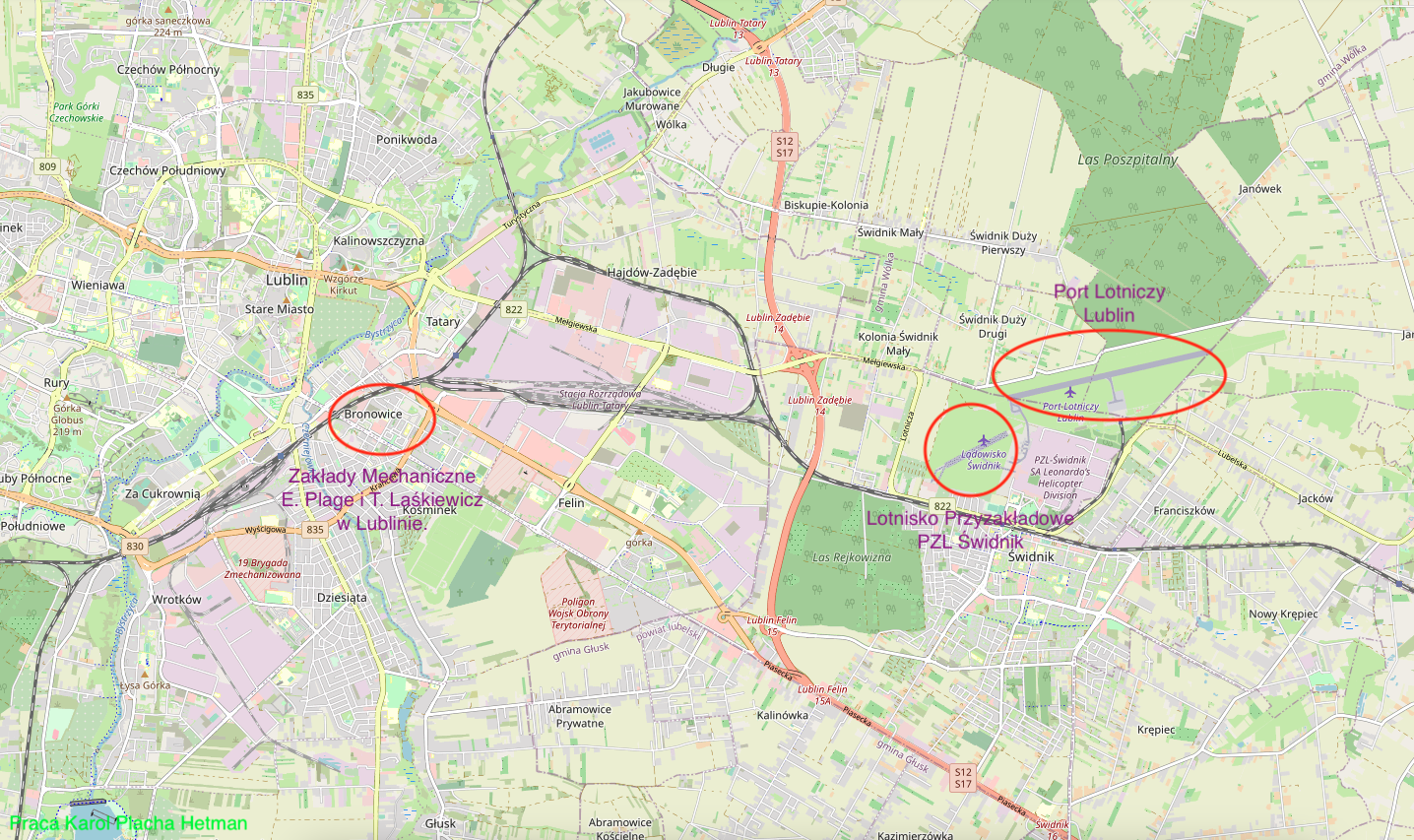

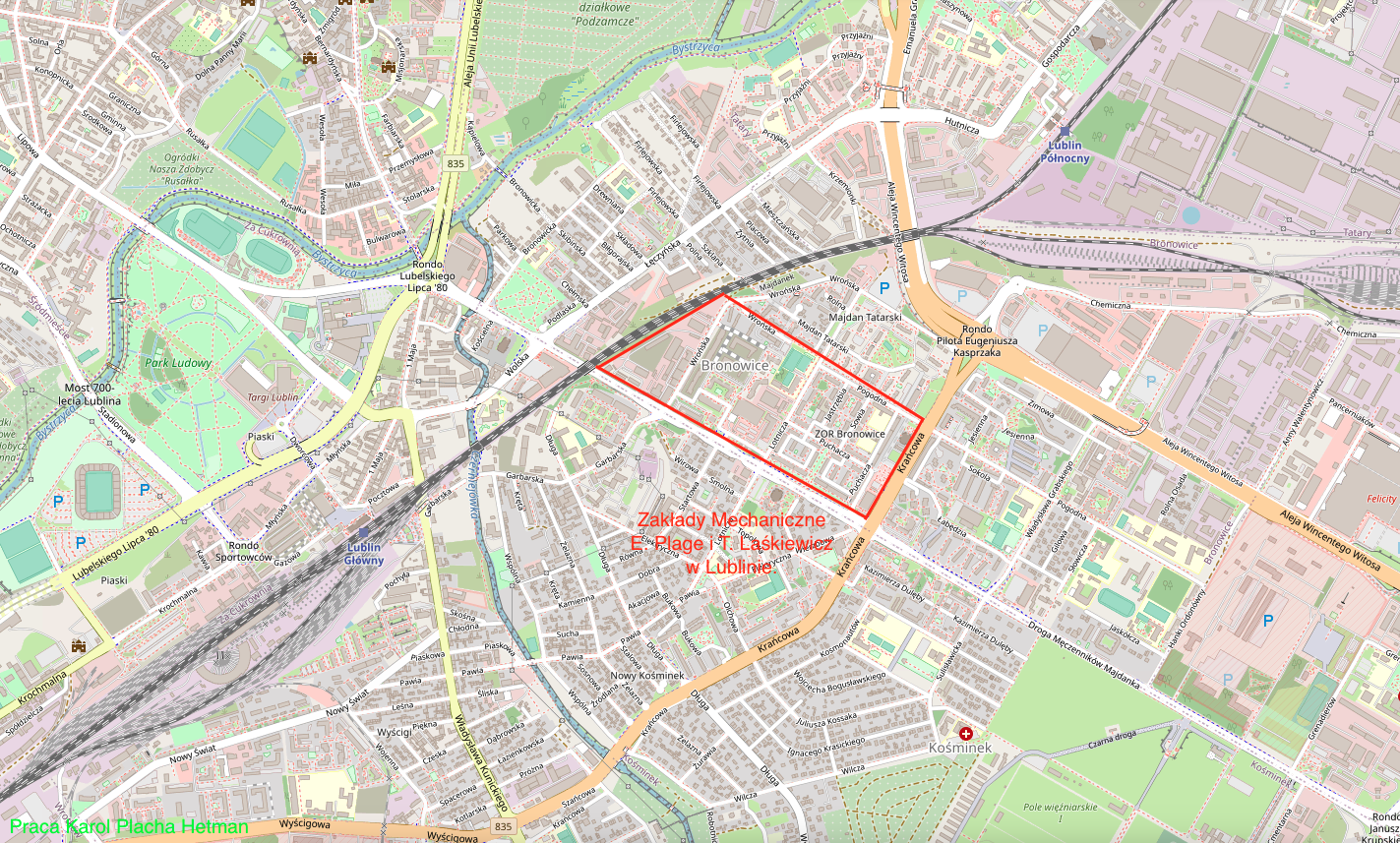

In 1899, Messrs. Emil Plage and Teofil Laśkiewicz founded a company and the famous "Zakłady Mechaniczne E. Plage i T. Laśkiewicz in Lublin" was established. The company was based in Lublin and was initially established for a period of 10 years. The co-shareholders bought the former Bronowice farm, which was located south of the center of Lublin, between the Bystrzyca River and the railway tracks. The shareholders built another factory here. Its location was well connected; there was a Warsaw-Kowal railway line and a road road to Zamość. Metal products for the food industry were still produced and were of very good quality, which was confirmed by the awards won at exhibitions. The range of manufactured products increased very quickly. Since 1907, the plant has been producing low- and high-pressure steam boilers on a large scale. The plant also produced iron structures for cement and sugar factories.

Both men were also active in other fields. Emil Plage promoted the development of sports and worked for charity. Teofil Laśkiewicz was the co-owner of the "Lublin" starch factory. He was the president of the Lublin Branch of the Association of Metal Industrialists and the Society of Craftsmen and Traders in Lublin. He was one of the founders and president of the Supervisory Board of the Christian Workers’ Loan and Savings Society in Lublin. He was also a member of the board of the Lublin Charitable Society.

The third creator of the plant’s power was engineer Kazimierz Arkuszewski, the most colorful character of the three. He came from a noble family from Greater Poland. He was born in 1970. He was exceptionally talented. He graduated from St. Petersburg with first place. He worked as an engineer-technologist in large metal works in Germani. Then he worked in Łódź in a large metal company of his cousin Józef Arkuszewski. The company dealt with water supply, sewage and central heating installations. At the turn of the century, the plant employed over 100 workers and was the largest in the Kingdom of Poland and the Moscow Empire, producing equipment for central heating, ventilation, waterworks, sewage, laundry, steam kitchens, baths, baths and others. The company had branches in St. Petersburg, Moscow, Kiev, Odessa and Rostov-on-Don. In 1904, Kazimierz Arkuszewski was already a shareholder in a company in Łódź, which employed nearly 120 employees and over 10 engineers. By 1905, the company had completed over 1,000 installations.

In 1909, Emil Plage died unexpectedly, leaving no descendants. His shares in the factory "Zakłady Mechaniczne E. Plage i T. Laśkiewicz in Lublin" passed to his parents, brother and sister. The company was still run by Teofil Laśkiewicz, and the interests of the Plage family were represented by Józef Laube. However, in 1910, Teofil Laśkiewicz and Kazimierz Arkuszewski decided to purchase Plage’s shares. The Plage family agreed to the sale, provided the Plage name was retained in the company name. This is what happened. Kazimierz Arkuszewski bought 90% and Teofil Laśkiewicz 10% of the shares.

Kazimierz Arkuszewski moved his companies from Łódź to Lublin. At that time, the plant in Lublin in Bronowice had two main production departments: copper and iron. The products went mainly to the food industry: distilleries, sugar refineries, breweries, starch factories and others in the Kingdom of Poland and the Muscovite state. Other products were also produced to order, such as; huge kerosene tanks. The company continued to produce boilers. In 1913, it began producing boilers for Russian warships. In May 1914, the company obtained a huge contract to build hulls for seagoing warships for the Russian army. Individual elements were to be made in Lublin, and the final assembly was carried out in Nowogród, at the Zablin factory. The assembly was performed by a team of fitters from Lublin. Before the Great World War, the plant employed about 300 workers.

The dynamic development of mechanical plants was stopped by the Great World War. Fortunately, the initial hostilities spared the factory. The plant was engaged in renovations of previously built installations and carried out small production for the needs of the army: field kitchens, boilers, canteens, canteens. In 1915, retreating Russian troops devastated the factory, and some of the equipment was taken away deep into Moscow. The plant did not go bankrupt, but it could only provide employment to 30 workers. Austria placed a small order for the needs of the army (field kitchens, canteens). The production of products for household needs slowly increased; pots, cans, bathtubs, ladles, cutlery.

An aircraft factory will be established.

In 1918, the Republic of Poland was reborn, which opened up new production possibilities for the factory. Kazimierz Arkuszewski became a supporter of aviation. He persuaded Teofil Laśkiewicz to start producing airplanes. At that time, the Air Navigation Section of the Ministry of Military Affairs decided on the need to produce airplanes in Poland and was looking for a factory that would undertake this task. Appropriate documents were sent from Lublin to Warsaw for permission to establish an aviation department. The Air Force Inspector, General Gustaw Mackiewicz, appointed a commission which confirmed the possibility of launching a new production in Lublin. A positive response to Lublin came on February 14, 1920. Another commission decided that the first planes built at the plant would be 300 Italian planes. Already on February 17, 1920, the company "Zakłady Mechaniczne E. Plage i T. Laśkiewicz in Lublin" signed an agreement with the Ministry of Military Affairs for the license production of aircraft; the Ansaldo A-1 "Balilla" fighter (200 pieces) and the Ansaldo A-300 reconnaissance and bomber (100 pieces).

The reader will easily see that events happened quickly. It is true that the Polish government approved the agreement only in February 1921, but it was already a formality. The ongoing war with Bolshevik Russia required decisive and quick actions. This is also why the first Italian machines were delivered to Warsaw by flight from Italy, so that they could enter the fight as soon as possible. The technical advantage of Italian aircraft over the Albatros commonly used at that time was enormous. The flight time of the planes was twice as long and exceeded 4 hours.

The contract of the plant in Lublin to produce a huge number of planes at that time (300 copies) was a great success for its owners, but also a big challenge. Kazimierz Arkuszewski himself headed the new department. More land was purchased for new production halls. The plant area increased from just over 1 ha to 14 ha. 10,000 square meters were covered. At that time, the plant had 51 buildings. The production halls of the aviation department had an area of approximately 3,000 square meters. For the needs of the new production, the owners bought a new locomotive with a capacity of 155 HP and a power plant with a capacity of 409 HP. Waterworks and collective sewage systems were built. The following departments were organized: auxiliary production, where patterns and templates were made, and a department for semi-finished metal parts (fittings, fuel tanks, engine beds and their covers). Most of the newly purchased land was devoted to the soaring field. In 1921, the factory employed about 600 people, including about fifty engineers and technicians. The monthly production capacity was: 40 tons of iron products, 4 tons of copper products, 7 tons of mechanical workshop products and 10 aircraft. It was a really large and modern production plant. Address; Lublin ul. Fabryczna 26.

Steam locomotive. – The first steam locomotive that was practically used was built in 1805. A locomotive was a power unit consisting of a steam boiler, a steam engine and a transmission device, usually a pulley. The device often had wheels for transportation, but these wheels were not powered. The steam boiler was fired with peat, wood or sawdust. Lokomobiles were cheap to operate, reliable and resistant to operating errors. They were widely used in the 19th century and early 20th century, in all factories.

The first Ansaldo A-300 aircraft built in Lublin was first flown on June 15, 1921. According to gossip, the quality of planes made in Lublin was low. There have been several disasters. This resulted in a reduction in the order. In particular years built; 1921 – 14 machines, 1922 – 22 machines, 1923 – 60 machines, 1924 – until production was stopped, 36 machines. The fact is that in 1921, the world aviation ace, pilot Adam Haber-Włyński, died while performing a stunt, and in 1922, as a result of wing detachment, Ensign J. Ryba and Sergeant W. Górski died. Therefore, Lublin planes did not enjoy a good reputation. In 1924, an investigation was carried out and a report was prepared, which stated that out of 110 aircraft, 18 had accidents and there were 9 fatalities, but only one was the fault of the plant. The blame should definitely be placed on faulty and underdeveloped Italian engines. The Italian airframes themselves had design flaws. They were designed for use in dry climates and had no protection against moisture. The adhesives used were not resistant to significant moisture and low temperatures, which was not taken into account initially. Only after some time it was realized that Polish wood used for aircraft products had different properties than Italian wood. That’s why a laboratory was opened at the factory. The wood was subjected to thorough classification already in sawmills, and then in Lublin it was subjected to a long drying and seasoning process. About problems with steel; tubes, wires, fittings, it was known from the very beginning that Polish steelworks did not produce exactly the same steel as was used in Italy. Polish steelworks were just beginning to master the production of various types of steel. It should also be added that specialists from Italy did not participate in the preparation for production process. Although the factory did not build 300 aircraft, the construction of 110 machines was also a great success and, above all, allowed it to gain extensive experience in the serial production of modern aircraft. Ansaldo A-1 "Balilla" planes in the American-Polish Kościuszko Squadron contributed significantly to stopping illiterate Budyonny’s large cavalry.

Technical data of the Ansaldo A-1 "Balilla" fighter aircraft, 1917. number of seats: 1 type: single-engine biplane construction: mixed structure with predominance of wood, plywood and canvas covering span: 7.68 m length: 6.84 m height: 2.53 m empty weight: 625 kg take-off weight: 870 kg maximum speed : 220 km/h range: 525 km flight time: 4.5 h power unit: FIAT SPA-6A inline engine with a power of 162 kW (220 HP) armament: 2 7.70 mm caliber Vickers machine guns, fixed synchronized, additionally two bombs.

Technical data of the Ansaldo A-300 reconnaissance and bomber aircraft from 1919. number of seats: 2 (pilot, observer) type: single-engine biplane construction: mixed structure with predominance of wood, plywood and canvas covering span: 11.24 m length: 8.75 m height: 2.97 m empty weight: 1140 kg take-off weight : 1,825 kg maximum speed: 200 km/h range: 500 km flight time: 3 h power unit: 6-cylinder FIAT A.12 bis inline engine with a power of 235 kW (320 HP) armament: 4 7.70 mm machine guns , bombs with a total weight of 190 kg.

In August 1921, in the factory’s technical office in Lublin, a design was developed for a two-seat, monoplane reconnaissance and bomber aircraft, powered by a FIAT A.12 bis engine with a power of 320 HP. The plane was marked ARLA-1 after the names of its owners: Kazimierz Arkuszewski and Teofil Laśkiewicz. However, no prototype was built.

As a result of the above-mentioned report, the factory improved its control system and introduced a number of changes in the production process. Modern machine tools were also purchased. The company’s activities and its achievements resulted in the factory easily obtaining an order in 1924 for the license production of French Potez XV airliners, 100 of which were produced in 1925-1926. A group of French technicians and engineers stayed on site in Lublin during the production of these aircraft. These planes were simultaneously produced in Biała Podlaska at the PWS – Podlaska Wytwórnia Samolotów plant. This was the first and not the only case in Poland when the same aircraft was produced in two factories. In this way, factories competed with each other in terms of the quality of their products.

The Potez XV plane was a relatively young and successful aircraft, but structurally rather outdated. Correct in piloting. However, it could not stay in aviation for long, because metal-wooden or completely metal structures were already appearing.

Technical data of the Potez XV reconnaissance and bomber aircraft, 1923. number of seats: 2 (pilot, observer) type: single-engine biplane construction: wooden structure, plywood and canvas covering span: 11.24 m length: 8.75 m height: 2.97 m empty weight: 1140 kg take-off weight: 1825 kg maximum speed: 200 km/h range: 500 km flight time: 3 h power unit: 6-cylinder FIAT A.12 bis inline engine with a power of 235 kW (320 HP) armament: 4 7.70 mm machine guns, bombs total weight 190 kg.

In 1925, Teofil Emeryk Laśkiewicz died at the age of only 54. He was buried in the family tomb in Lublin at Lipowa Street. His death caused unconcealed sadness in almost all of Lublin. His son Roman Laśkiewicz, then only 22, inherited his father’s shares in the company.As a result of the above-mentioned report, the factory improved its control system and introduced a number of changes in the production process. Modern machine tools were also purchased. The company’s activities and its achievements resulted in the factory easily obtaining an order in 1924 for the license production of French Potez XV airliners, 100 of which were produced in 1925-1926. A group of French technicians and engineers stayed on site in Lublin during the production of these aircraft. These planes were simultaneously produced in Biała Podlaska at the PWS – Podlaska Wytwórnia Samolotów plant. This was the first and not the only case in Poland when the same aircraft was produced in two factories. In this way, factories competed with each other in terms of the quality of their products.

The Potez XV plane was a relatively young and successful aircraft, but structurally rather outdated. Correct in piloting. However, it could not stay in aviation for long, because metal-wooden or completely metal structures were already appearing.

Technical data of the Potez XV reconnaissance and bomber aircraft, 1923. number of seats: 2 (pilot, observer) type: single-engine biplane construction: wooden structure, plywood and canvas covering span: 11.24 m length: 8.75 m height: 2.97 m empty weight: 1140 kg take-off weight: 1825 kg maximum speed: 200 km/h range: 500 km flight time: 3 h power unit: 6-cylinder FIAT A.12 bis inline engine with a power of 235 kW (320 HP) armament: 4 7.70 mm machine guns, bombs total weight 190 kg.

In 1925, Teofil Emeryk Laśkiewicz died at the age of only 54. He was buried in the family tomb in Lublin at Lipowa Street. His death caused unconcealed sadness in almost all of Lublin. His son Roman Laśkiewicz, then only 22, inherited his father’s shares in the company.

During this period, the plant launched two more important programs for the plant. The first was to organize his own aircraft design office. The owners of aviation factories, not only in Lublin, but also in Poznań and Biała Podlaska, painfully felt that they could not function solely by counting on government orders for licensed production. Aircraft production was still specific. The sales market in Poland was limited, and only those with their own aircraft structures could look for buyers abroad. Serial construction of airplanes in small quantities was not very profitable, because the plane for sale had to be expensive and few could afford it. With mass production, it was possible to calculate a lower price, find more people willing to buy, and at the same time beat competitors. In 1924, the Ministry of Military Affairs announced a competition for a heavy multi-engine bomber for the Polish Army. An employee of the design office, Jerzy Rudnicki, designed a twin-engine, biplane bomber, designated Lublin R-VII Odwet. The design of the aircraft was mixed. The plant had two in-line 6-cylinder FIAT A.12 bis engines with a power of 235 kW (320 HP) as the drive. The crew was to consist of a pilot and three or four observers-gunners. The project was sent by post to Warsaw and was lost. Ultimately, none of the projects even entered the model construction phase.

The second initiative was to start the production of bodies for passenger cars, buses and trucks. Please note that the production capacity of the factory in Lublin was 10 aircraft per month. These abilities were not used. Therefore, going into the automotive sector was a good move. In the period 1924-1933, "Zakłady Metalowe Plage i Laśkiewicz in Lublinie" produced bodies of Somua and Ursus AW buses and Ursus A trucks. Then, in the period 1925-1931, passenger cars were also built on imported chassis; "Chrysler", "Buick", "Hotchkiss", "Auburu", described as luxurious. The plant purchased complete chassis with running gear and engines and built bodies on them. The production of steam boilers for steam locomotives, ships and boiler houses also continued. The boilers were installed mainly in steam locomotives and narrow-gauge railways.

After the end of production of Potez XV aircraft, the factory received another order for the license production of Potez XXV airliners, 150 of which were produced in the period 1928-1931. This type was also produced in parallel in Lublin and Biała Podlaska at the PWS – Podlaska Wytwórnia Samolotów plant.

In 1927, engineer Jerzy Rudlicki, as a talented aircraft designer, was appointed chief designer of the office in Lublin. Jerzy Rudlicki was a graduate of the aviation school in Paris. From then on, the era of Lublin construction began. In mid-1927, a plan was created for the aircraft, which was designated Lublin R.VIII. Engineers Jerzy Dąbrowski and Antoni Uszacki also worked on the plane. The plane was to meet the requirements of a reconnaissance and bomber, which in Poland was also called an airliner. The project was presented to the Ministry of Military Affairs. On December 14, 1927, the factory signed an agreement to build three prototypes. The first prototype was ready on February 8, 1928, but due to delays in deliveries of French Farman 12 WE engines with a power of 404 kW (550 HP), the first flight was performed on March 15, 1928. Then the plane flew to Warsaw for tests at the Aviation Technical Research Institute. The machine received a positive opinion with the recommendation to install a more powerful drive unit. Lorraine-Dietrich engines with a power of 478 kW (650 HP) were purchased in France. The second prototype, marked Lublin R.VIII/2, was equipped with these engines and first flew in July 1928. This aircraft became a model for production machines. At this time, similar Hispano-Suiza aircraft engines were acquired, also with a power of 478 kW (650 hp). On March 13, 1929, the plant signed a contract to build the first series of 4 machines. All machines were built by mid-1930. At that time, the army began to question the sense of building more planes and spending state money when the army had a sufficient number of reconnaissance and bomber (linear) planes. Even the ability of the structure to meet the requirements began to be questioned. The company owners did not give up their weapons. In April 1930, the Navy command was approached with an offer to convert four Lublin R.VIII aircraft into water planes with a float landing gear. The final agreement was concluded on February 26, 1932. These aircraft were sometimes called Lublin R.VIII hydro. Including prototypes, 9 Lublin R.VIII aircraft of all varieties were produced. In October 2015, a well-preserved propeller of the Lublin R.VIII hydro plane and its 12-cylinder engine were found in the Bay of Puck.

Technical data of the Lublin R.VIII 1928 reconnaissance and bomber aircraft. number of seats: 2 (pilot, observer) type: single-engine biplane construction: mixed structure with predominance of wood, covered with plywood and canvas. The landing gear was classic fixed with a tail skid. In the water version there were two multi-bulk metal floats from Short attached to the lower wing. Each float had a profiled bottom and a water rudder. span: 17.00 m length: 11.12 m (with floats 13.20 m) height: 4.50 m (with floats 5.33 m) empty weight: 2,200 kg (with floats 2,800 kg) take-off weight: 4,200 kg maximum speed: 220 km/h (with floats 200 km/h) range: 1,500 km flight time: 7.5 h power unit: Lorraine-Dietrich 12-cylinder in-line engine with a power of 478 kW (650 HP) or Hispano-Suiza also with a power of 478 kW (650 HP) armament: 3 7.69 mm machine guns, bombs with a total weight of 300 kg.

In 1929, the prototype of the Lublin R.IX passenger plane was flown, which was based on the R.VIII design. The plane was designed by Jerzy Rudlicki at the end of 1928. At that time, the airlines, as well as the Air and Gas Defense League, were looking for a passenger plane. The conversion of combat aircraft into transport aircraft (passenger and cargo) is a common trend all over the world. Designs proven in the military were much more willingly accepted by passengers as they were very safe. Especially since transport planes do not have to perform higher pilotage figures. In the Lublin R.IX plane, the pilot’s cabin was left uncovered. The passenger cabin was placed inside the raised fuselage. However, the cabin was not high enough to allow a standing position. Six seats were installed in pairs in the interior, and doors and windows were placed in the sides. The drive was powered by a Gnôme-Rhône Jupiter 9A radial engine with a power of 353 kW (480 HP). The prototype first flew on April 18, 1929. The plane was shown at the General National Exhibition in Poznań in June 1929. However, the design did not gain recognition among potential buyers. The authorities of LOT Polish Airlines automatically compared the Lublin R.IX aircraft to the Fokker F-VIIA/1m and Junkers F-13 aircraft. Attention was drawn to lower performance (max speed 175 km/h, range 700 km) and more labor-intensive operation. The plane was placed in an airship hangar at the Ławica airport, and after a few years it was deleted.

In the period 1929-1930, the plant produced, under license from Fokker, 11 Fokker F-VIIB/3m passenger aircraft and another 20 units in the independently developed bomber version. There were probably 9-10 more machines built for France and Belgium. These planes were delivered to LOT Polish Airlines and the Polish Army, where they were used, among other things, to perform parachute landings. The factory in Lublin offered the military a version of the Fokker F-VIIB/3m on a float chassis, armed with an 800 kg aircraft torpedo. The node for attaching and dropping the torpedo was developed by engineer W. Świątecki. However, the Navy did not place an order.

Technical data of the Fokker F-VII/3m multi-role aircraft from 1929. number of seats: 2-3 pilots type: single-engine high-wing monoplane construction: mixed structure, wooden wings, fuselage made of steel pipes span: 21.71 m length: 14.56 m height: 3.90 m empty weight: 2,600 kg take-off weight: 4,500 kg maximum speed: 185 km/h range: 1240 km flight time: 5 h power unit: 3 9-cylinder Wright J5B Whirlwind radial engines with a power of 3 x 162 kW (3 x 220 HP) armament: 1 7.70 caliber machine gun mm on the back of the hull, bombs with a total weight of 1000 kg, in the passenger version 10 people.

However, the plant in Lublin did not give up developing its own passenger aircraft. In 1930, the design was developed into the Lublin R.XI passenger aircraft. The plane was created for a competition of the Ministry of Communication. The competitor was the plane of Podlaska Wytwornia Samolotów PWS-21 bis. The Lublin R.XI aircraft used the solutions used in the Fokker F-VIIB aircraft. The airframe primarily received a single lobe with an elliptical outline. The panel was made of a wooden structure. The hull was also enlarged and was made of welded chrome-molybdenum pipes. The pilot’s cabin was moved forward and placed between the engine and the wings. The cockpit was completely glazed. There were dual controls in the cockpit, so the plane could be piloted by two pilots. The passenger cabin had only 4 seats. One radial engine was used for propulsion, surrounded by a Townend ring. The prototype received the registration marks SP-ACC and made its first flight on February 8, 1930. After factory tests, the plane was transferred to PLL LOT at the Mokotów airport in June 1930. Unfortunately, after a few flights the plane was damaged. The renovation was completed only in 1931. A few more flights were made on it and in July 1931 it crashed again. The structure was not ordered by the airline.

However, based on the conclusions obtained from the tests of the Lublin R.XI passenger aircraft, in 1931, the Ministry of Communication ordered a new prototype from the factory, marked Lublin R.XVI. The plane first flew in February 1932 and, after factory tests, was sent to the Aviation Technical Research Institute (IBTL) in May of that year. The plane entered the competition together with the PWS-24 plane, which was a development of the PWS-21. Both planes were comparable and similar in performance. The competition was won by the PWS-24 aircraft, and the Lublin R.XVI aircraft was returned to Lublin to strengthen the structure and install a more powerful 365 HP Wright engine. The factory did not modernize the existing machine, but built a new prototype, marked R.XVI a/2. Construction began in November 1932, but the first flight took place only on November 9, 1933. The plane successfully passed tests at IBTL in 1934 and was sent for trial operation at LOT Polish Airlines. The tests lasted until 1935, after which the aircraft was not accepted and was canceled in 1936. The fact is that already in 1935, LOT Polish Airlines was conducting serious talks with Lockheed regarding the purchase of Lockheed L-10 Electra aircraft. A twin-engine, all-metal machine with good navigation equipment.

Engineer Jerzy Rudlicki, using the Lublin R.XVI airframe, developed a sanitary version with the letter "b" in its name. The plane was carrying a pilot, a doctor and two patients on stretchers. The prototype first flew in May 1933 and was handed over to the army to check its suitability. On June 1-4, 1933, the plane was demonstrated in Madrid during the 7th International Congress of Aeronautical Medicine, where the Polish design was a huge success, winning first place. The following designs were defeated: the French Potez 29, the American Ford Trimotor and the English Avro 564. This success resulted in the Polish Army ordering 5 Lublin R.XVI b machines, which were delivered in March 1935.

In December 1927, at its own risk, the factory began to develop a liaison aircraft, rightly suspecting that the army would soon announce a competition for this type of machine. The project was led by Eng. Jerzy Rudlicki. In 1928, two prototypes were made; one for static tests, the other for flight tests. In December 1928, the prototype underwent static tests. The Ministry of Military Affairs became interested in the aircraft and on February 1, 1929, the second prototype, designated Lublin R.XIII, was flown with military markings on the fuselage. Because it was winter, take-off and landing tests were also performed with ski landing gear. The plane had good flight characteristics, high maneuverability, responded correctly to the controls, and had a short take-off and landing roll. The plane had easily foldable and unfolding wings. Thanks to this, the machines could be hidden even in a small barn or transported by road or rail. The tests at the Institute of Technical Research of Aviation (IBTL) in Warsaw at the Mokotów airport were carried out in March 1929. The Lublin R.XIII plane turned out to be capable of performing full aerobatics. On the plane, a muffler was installed on the engine exhaust system, which made the plane flying at an altitude of 300 m almost inaudible on the ground. The army placed an order for five aircraft of the first test series. The planes were designated Lublin R.X-a.

After building a series for the army, in July 1929 the factory built a Lublin R.X plane in a rally version, which received the registration SP-ABW, serial number 52.7. The plane had several significant changes. Each cylinder received its own exhaust. The fuel tank was so large that it allowed for a 15-hour flight. The machine was shown at the General National Exhibition in Poznań. Then the plane received an additional engine enclosed with a Townend ring and a metal propeller. The avionics equipment included an artificial horizon and a gyroscopic compass. The fuel installation has been enlarged once again, allowing the flight time to be extended to 18 hours. The aircraft’s designation was then changed to Lublin R.X-a bis and the name "Srebrny Ptak" was added. This plane made several long-distance flights. Among others, Warsaw-Barcelona without landing, 1,800 km long. In 1931, the plane flew to around Poland without landing. Distance 1650 km. Then, in 1932, the Lublin R.X bis "Srebrny Ptak" plane flew to Herad in Afghanistan, covering a distance of 14,390 km. In the fall of 1933, the plane was damaged. Already in April 1933, a similar aircraft was built, marked Lublin R.XXIII (R.XIII Dr), although it is better known as Lublin R.XIII Dr and had its own name "Blue Bird". It was a typical rally plane based on the Lublin R.XIII-b airframe. The plane was registered SP-AJT. On October 21-November 10, 1935, the crew; S. Karpiński, W. Rogalski performed a flight on the Warsaw – Istanbul – Baghdad – Karachi – Kolkata – Bangkok – Preczubab route. In the latter town, the plane was damaged during take-off on a muddy landing field and the planned flight to Melbourne did not take place. The Blue Bird was transported to the country by ship and canceled the following year.

The machines transferred to the army were equipped with a movable machine gun located on a turntable in the rear cabin. The planes were tested in the 2nd Aviation Regiment at the Rakowice-Kraków airport. In December 1929, the army conducted comparative tests of three aircraft: PWS-5, PZL Ł-2 and Lublin R.X-a. Equal first place was taken by PZL Ł-2 and Lublin R.X. According to other opinions, Lublin R.X was clearly better. The fact is that the army placed an order for a plane from Lublin. However, this order was canceled because the modernized Lublin R.XIV appeared. A total of 7 Lublin R.X. aircraft were built. All of them served in the Polish Army, mainly as liaison and dispatch aircraft. They were equipped with radio stations and a device for receiving reports from the ground during flight.

Technical data of the Lublin R.X liaison aircraft, 1929; number of seats: 2 type: single-engine monoplane high-wing monoplane design: mixed structure, wooden wings, foldable, fuselage made of steel pipes span: 13.50 m length: 8.30 m height: 2.98 m empty weight: 900 kg take-off weight: 1370 kg maximum speed: 170 km/h range: 750 km (bis version 2,700 km) flight time: 18 h power unit: 9-cylinder Wright J5B Whirlwind radial engine with a power of 3 x 162 kW (3 x 220 HP) armament: 1 gun machine gun caliber 7.70 mm.

The Lublin R.X variant of the aircraft was mass-produced under the Lublin R.XIII designation from 1930 and was a huge success. The plane was adopted by the Polish Army as an accompanying (liaison) machine. Initially, the plane was produced under the designation Lublin R.XIV, because the factory avoided giving the number 13 due to superstitions among the crew. In the period 1930-1931, 15 machines were built. Later, the plane was slightly modernized and was marked Lublin R.XIII. The decision on this numbering was made personally by engineer Jerzy Rudnicki. In the years 1932-1935, another 273 machines were built in 11 series, differing in equipment.

In 1930, at the request of Ligia (LOPiP), a single sports plane was created, with a layout referring to the Lublin R.X. The plane was marked Lublin R.XII and received civilian registration. It is equipped with a small 5-cylinder Armstrong-Siddeley Genet radial engine with a power of 80 HP. The plane made its first flight in the fall of 1930. LOPiP did not take delivery of the plane, arguing that the design did not meet their needs. The plane stood in a hangar for several years and then was written off.

The factory in Lublin had its own test pilots who conducted their own factory tests. State tests were carried out at the Aviation Technical Research Institute in Warsaw at the Mokotów airport. The plant in Lublin not only produced ready-made aircraft, but also repaired them and supplied spare parts to users. The factory ran its own vocational school, which prepared specialists in aviation professions (aircraft carpenters, welders, wood and metal machine operators). The management promoted sports. There was a volleyball sports club that played in the Polish league.

Continued in the next chapter.

Written by Karol Placha Hetman