Kraków 2020-11-01

The history of the Iwczenko AI-25 turbojet engine

The history of Ivchenko’s aircraft engines began in 1945, at the Ukrainian CCCP in Zaporizhia. At that time, the OKB-478 design office and experimental plant were organized. The task of the OKB-478 office was to develop aircraft engines for airplanes and helicopters as well as other machines and devices for industry. The office was headed by Alexander Grigoryevich Ivchenko (Олександр Георгійович Івченко 1903-1968), who held this position until 1968, when he died. Later, the plant changed its name to Ivchenko Lotarev. Vladimir Lotariev managed the office in 1968-1989. The design office and the plant operate to this day under the name Ivchenko-Progress ZMKB ЗМКБ «Прогрес» ім. О. Г. Івченка. The engines constructed in Zaporizhia propel the world’s largest aircraft, An-225, as well as the world’s largest helicopter, the Mi-26. For many years, the office cooperated with Poland and Czechoslovakia within the Comecon (Mutual Economic Assistance Council). At CCCP, the design offices have always been separate from the production facilities, unlike in the West. Therefore, the typical production of engines was carried out by the Motor Sich plant (Motor Sich) located at the airport in Zaporizhia.

In the office, they developed the AI-14 (200 kW) and AI-26 (400 kW) piston engines, the AI-20 (3,000 kW) and AI-24 (1,900 kW) turboprop engines and the AI-25 dual-flow engine. The engines were used in AntonoW, Iliuszyn, Jakowlew airplanes, Kamow and Mila helicopters and foreign constructions. The AI-14 and AI-26 engines were also produced under license in Poland.

Initially, piston engines with the designation AI were designed in OKB-478. Later, turbine engines, both turboprop and turbojet, began to be designed. The first was the TS-12 engine, on which work began in 1953. At the beginning of the 60’s, the design of two-flow engines began. In 1971, Vladimir Lotarev developed the first Russian engine of the Lotariev D-36 turbofan class.

The AI-25 engine was the first OKB-478 two-flow turbojet engine. It belongs to the low thrust engines. It was installed in the Aero L-39 Albatros training and training planes, the Jak-40 transport, and the agricultural PZL M-15 Belfegor aircraft and was planned for the training and training Yak-30. The works started at the beginning of 1965. The first engine start-up took place in 1966, and production was started in 1967. The AI-25 engine was the most successful powering the Aero L-39 Albatros aircraft. On the other hand, the engine performed very poorly as a drive for the Yak-40 aircraft, mainly due to high fuel consumption. The aircraft equipped with three AI-25 engines with nominal load has a range of only 600-800 km, which was a tragic result compared to Western designs. The engine also went to China.

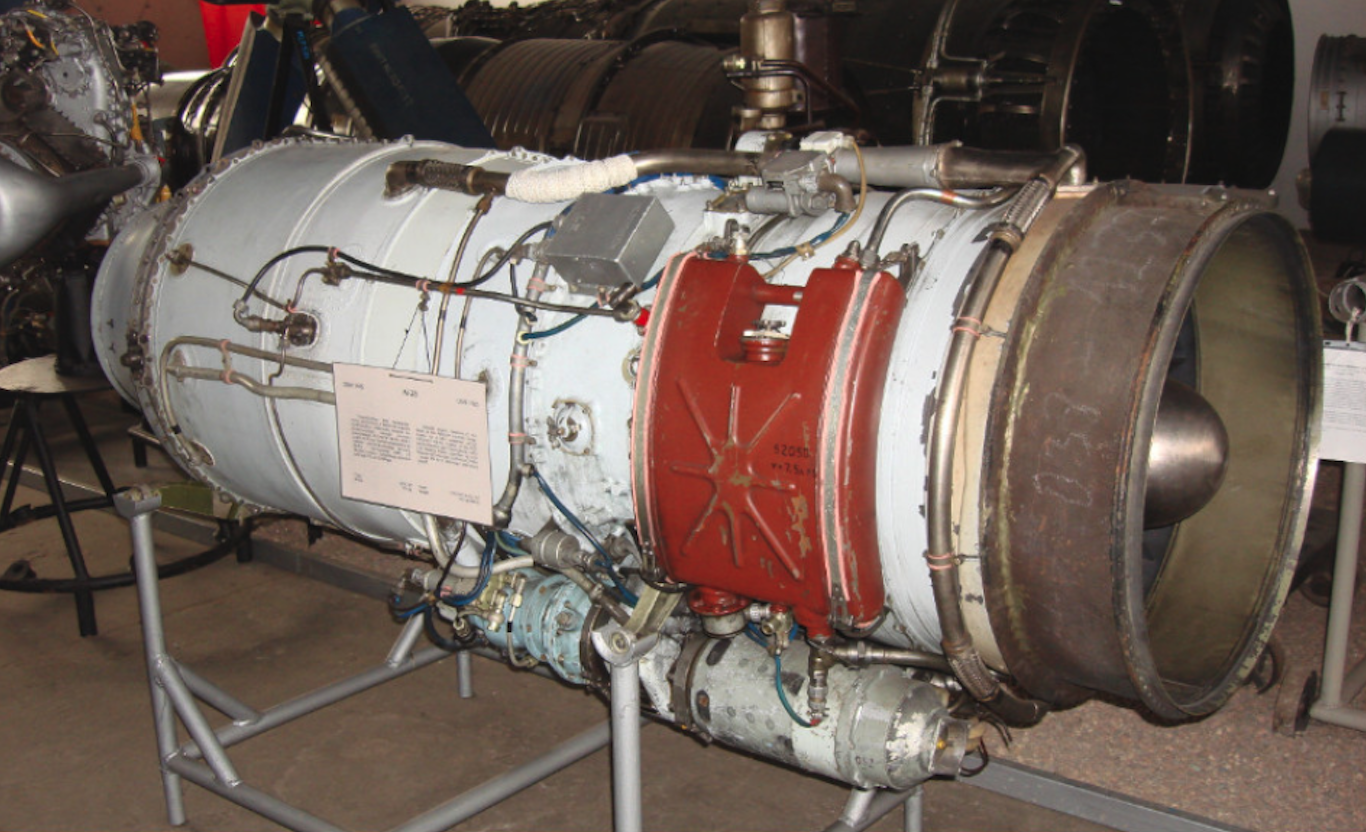

Construction of the AI-25 engine.

The AI-25 engine is a two-flow, single-shaft (single-spool) engine, designed to reach speeds of up to 1,000 km / h. The engine consists of 3-stage low pressure compressor, 8-stage high pressure compressor, annular combustion chamber preceded by 12 blades, single stage high pressure turbine, single stage low pressure turbine. The maximum thrust is 14.7 kN (1,500 kG). Nominal thrust 10.98 kN (1,120 kG). The engine may be fitted with a thrust reverser. Length 3.35 m, diameter> 1.00 m. Engine weight 290 kg and 350 kg with the thrust reverser. The engine has anti-wetness, fire protection and de-iced nacelle air intakes. Each of the engines has an individual oil installation. The oil is cooled in the heat exchanger by the fuel flowing to the engine. For its construction, titanium, aluminum and magnesium were used. In the Yak-40, an APU type AI-9 start-up turbine engine is used to start the engines, installed above the fuselage in the air intake fairing for the middle engine. Its outlet is located on the right side of the vertical tail.

Basic data of the AI-25 engine:

The engine was produced in Ukraine at the time of the CCCP. The maximum thrust is 14.7 kN (1,500 kG). The engine weight is 312 – 353 kg. Engine length 1.99 m. Engine height 0.896 m. Engine width 0.820 m. Compression ratio is 8: 1. Annular combustion chamber. The maximum temperature of the turbine gases is 630 degrees Celsius.

Written by Karol Placha Hetman